Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo MS&T Process Engineer in the Pharmaceutical Industry: Streamlining Collaboration to Enhance Process Excellence

What do you need to know about this challenge?

In the context of the pharmaceutical industry, an MS&T Process Engineer grapples with the crucial challenge of streamlining collaboration to ensure that process excellence is achieved and maintained. This involves enabling seamless communication and cooperation across various departments to troubleshoot process variances, implement robust quality controls, and innovate for better production efficiency within a strictly regulated sector.

What can you do with KanBo to solve this challenge?

- Increase Process Visibility: Use KanBo’s Kanban view to visualize the entire manufacturing process, providing transparency and allowing for real-time tracking of progress across different process stages.

- Promote Real-Time Communication: Employ user activity stream to enable instant communication among team members, which is essential for coordinating process changes and updates.

- Foster Proactive Problem Solving: Utilize card blocker to identify and manage issues in real-time, preventing delays and fostering a culture of proactive problem solving.

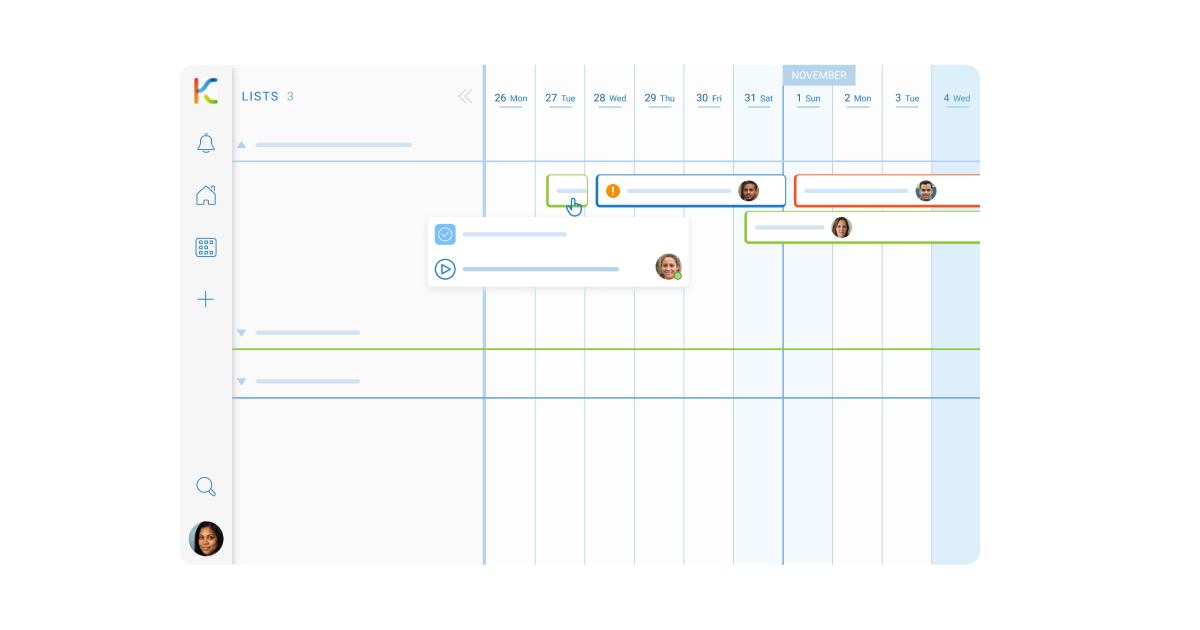

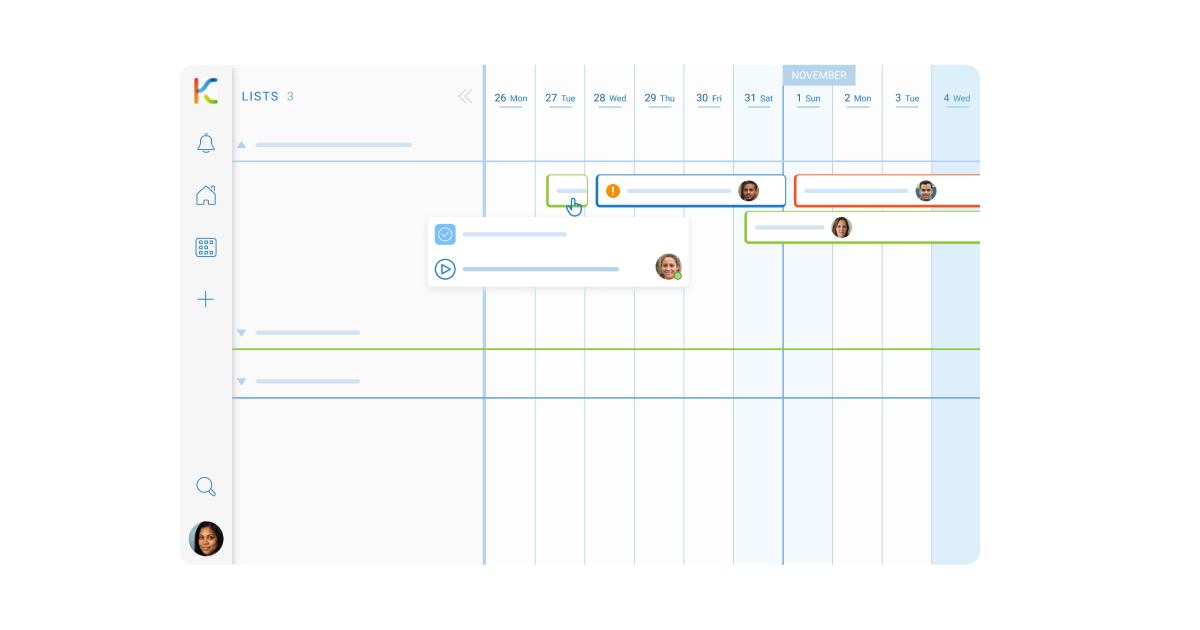

- Facilitate Efficient Scheduling: Leverage the Timeline view to schedule and manage engineering runs effectively, mitigating potential overlaps and ensuring optimal utilization of resources.

- Streamline Documentation: Apply document source to integrate process documents and SOPs directly into KanBo cards, reducing the time needed to access key information and ensuring current practices are easily available for the team.

- Speed Up Information Retrieval: Incorporate filtering cards for quick searching and sorting of critical process information, thus speeding up the process consultation and information retrieval during complex problem-solving.

What can you expect after solving this challenge?

By leveraging KanBo to tackle the collaboration challenge within the realm of MS&T Process Engineering, readers can look forward to a future of enhanced operational harmonization. There will be an improvement in the interdepartmental workflow, leading to greater process stability and compliance. Real-time data will drive decision-making, potentially reducing downtime and hastening response to quality issues. A comprehensive overview of ongoing processes will ensure continuous improvement and drive efficiency. Future enhancements in KanBo features are expected to offer even more refined collaboration tools, steering towards an era of unrivaled precision in the orchestration of pharmaceutical engineering processes.

Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo MS&T Process Engineer in the Pharmaceutical Industry: Streamlining Collaboration to Enhance Process Excellence

What do you need to know about this challenge?

In the context of the pharmaceutical industry, an MS&T Process Engineer grapples with the crucial challenge of streamlining collaboration to ensure that process excellence is achieved and maintained. This involves enabling seamless communication and cooperation across various departments to troubleshoot process variances, implement robust quality controls, and innovate for better production efficiency within a strictly regulated sector.

What can you do with KanBo to solve this challenge?

- Increase Process Visibility: Use KanBo’s Kanban view to visualize the entire manufacturing process, providing transparency and allowing for real-time tracking of progress across different process stages.

- Promote Real-Time Communication: Employ user activity stream to enable instant communication among team members, which is essential for coordinating process changes and updates.

- Foster Proactive Problem Solving: Utilize card blocker to identify and manage issues in real-time, preventing delays and fostering a culture of proactive problem solving.

- Facilitate Efficient Scheduling: Leverage the Timeline view to schedule and manage engineering runs effectively, mitigating potential overlaps and ensuring optimal utilization of resources.

- Streamline Documentation: Apply document source to integrate process documents and SOPs directly into KanBo cards, reducing the time needed to access key information and ensuring current practices are easily available for the team.

- Speed Up Information Retrieval: Incorporate filtering cards for quick searching and sorting of critical process information, thus speeding up the process consultation and information retrieval during complex problem-solving.

What can you expect after solving this challenge?

By leveraging KanBo to tackle the collaboration challenge within the realm of MS&T Process Engineering, readers can look forward to a future of enhanced operational harmonization. There will be an improvement in the interdepartmental workflow, leading to greater process stability and compliance. Real-time data will drive decision-making, potentially reducing downtime and hastening response to quality issues. A comprehensive overview of ongoing processes will ensure continuous improvement and drive efficiency. Future enhancements in KanBo features are expected to offer even more refined collaboration tools, steering towards an era of unrivaled precision in the orchestration of pharmaceutical engineering processes.