Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Manufacturing Systems Expert in the Pharmaceutical Industry: Tackling the Digital Collaboration Challenge

What do you need to know about this challenge?

In the pharmaceutical industry, a Manufacturing Systems Expert is often tasked with the complex challenge of effectively digitizing collaboration in a highly regulated GxP environment. This includes transitioning paper-based processes to electronic ones, increasing automation, ensuring documentation compliance, and continuous systemic improvement – all while collaborating with various department experts.

What can you do with KanBo to solve this challenge?

KanBo is equipped with features designed to assist in overcoming the challenges of digital collaboration:

- Digital Documentation: Use KanBo's card system to manage electronic documentation effectively, replacing paper-based processes and ensuring GxP compliance.

- System Integration: Employ the document source feature to integrate various IT systems and process controls into the digital documentation workflow, enhancing accessibility and reliability of information.

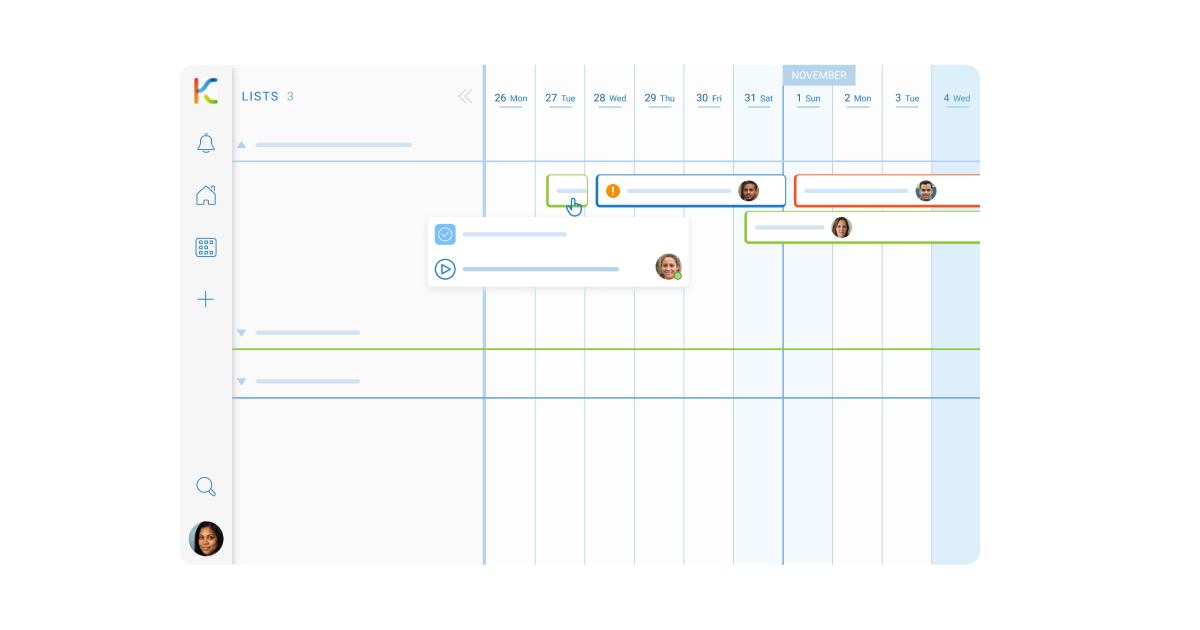

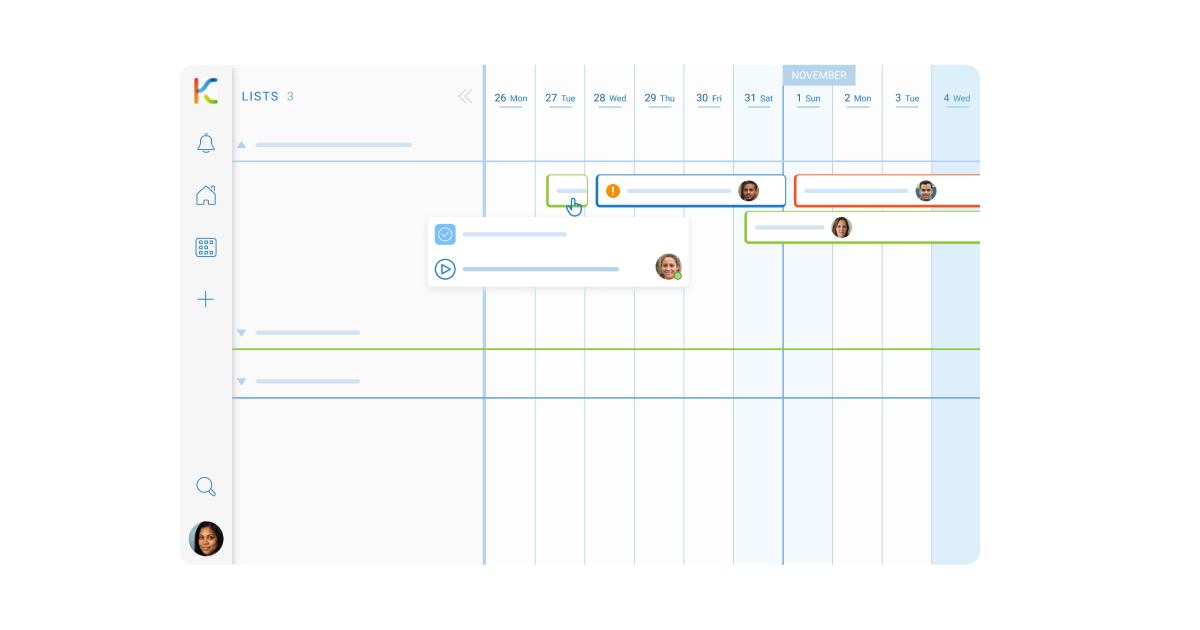

- Continuous Improvement: Utilize the timeline and Gantt Chart view to plan, track, and analyze the process of transitioning to a new eBR system, identifying opportunities for improvement and streamlining implementation phases.

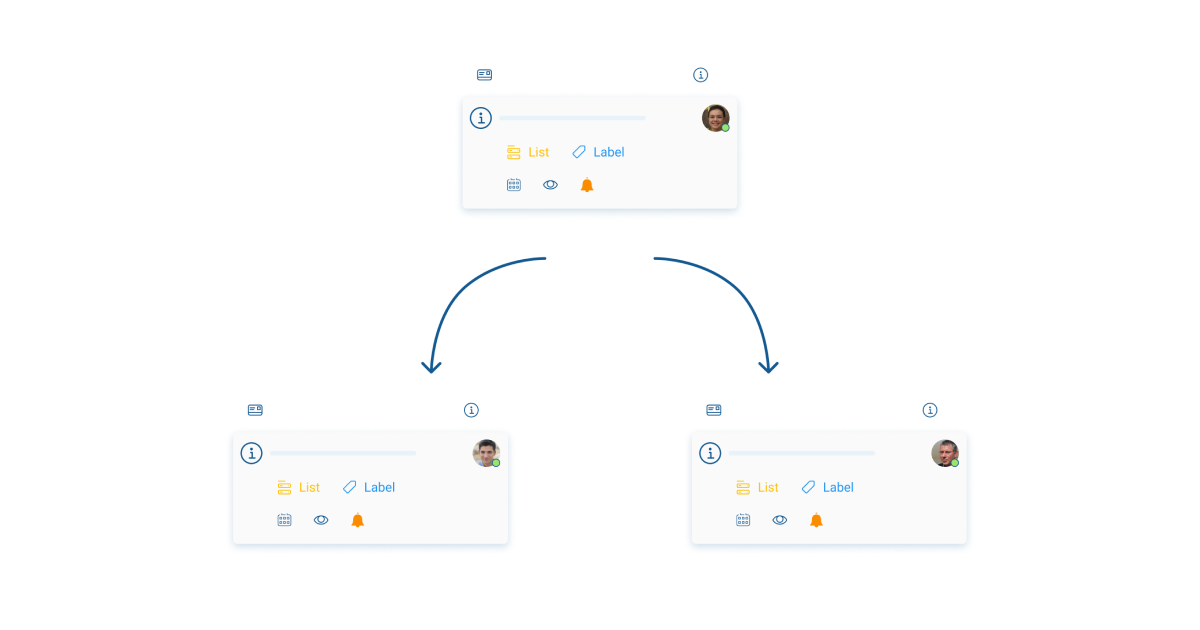

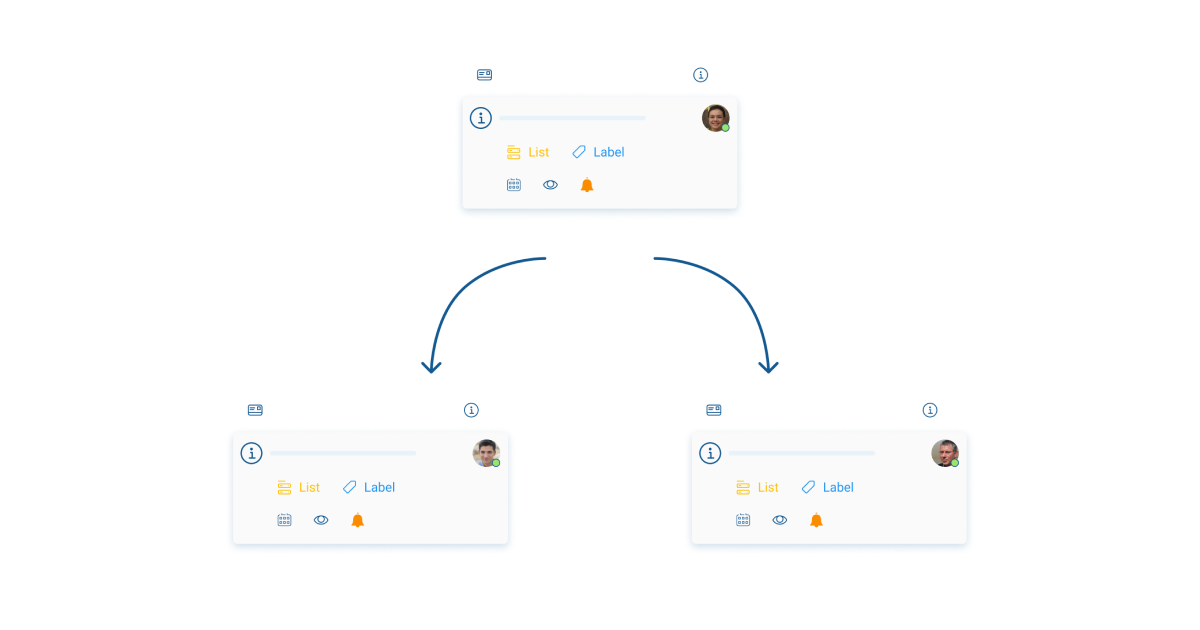

- Automated Information Processing: Set up card relations to link related processes and automate the flow of information, ensuring data consistency across the manufacturing system.

- Troubleshooting Transparency: Leverage the card activity stream for real-time monitoring of updates and changes, facilitating efficient troubleshooting and cross-departmental communication.

- Effective Process Management: Apply Kanban view to visualize stages of digital transformation and track the progress of integrated systems, supporting better management of process changes.

What can you expect after solving this challenge?

After successfully incorporating KanBo to tackle the digital collaboration challenge, you can expect substantial long-term benefits within the pharmaceutical industry. Enhanced digital integration leads to improved compliance with regulatory standards, increased operational efficiency, and a significant reduction in process errors. Moreover, the increased transparency and communication facilitated by KanBo's features such as card activity streams contribute to a culture of continuous improvement. As digital needs evolve, the adaptability and scalability of KanBo's tools will enable further enhancement of collaboration strategies, securing its role as a crucial asset for any Manufacturing Systems Expert.

Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Manufacturing Systems Expert in the Pharmaceutical Industry: Tackling the Digital Collaboration Challenge

What do you need to know about this challenge?

In the pharmaceutical industry, a Manufacturing Systems Expert is often tasked with the complex challenge of effectively digitizing collaboration in a highly regulated GxP environment. This includes transitioning paper-based processes to electronic ones, increasing automation, ensuring documentation compliance, and continuous systemic improvement – all while collaborating with various department experts.

What can you do with KanBo to solve this challenge?

KanBo is equipped with features designed to assist in overcoming the challenges of digital collaboration:

- Digital Documentation: Use KanBo's card system to manage electronic documentation effectively, replacing paper-based processes and ensuring GxP compliance.

- System Integration: Employ the document source feature to integrate various IT systems and process controls into the digital documentation workflow, enhancing accessibility and reliability of information.

- Continuous Improvement: Utilize the timeline and Gantt Chart view to plan, track, and analyze the process of transitioning to a new eBR system, identifying opportunities for improvement and streamlining implementation phases.

- Automated Information Processing: Set up card relations to link related processes and automate the flow of information, ensuring data consistency across the manufacturing system.

- Troubleshooting Transparency: Leverage the card activity stream for real-time monitoring of updates and changes, facilitating efficient troubleshooting and cross-departmental communication.

- Effective Process Management: Apply Kanban view to visualize stages of digital transformation and track the progress of integrated systems, supporting better management of process changes.

What can you expect after solving this challenge?

After successfully incorporating KanBo to tackle the digital collaboration challenge, you can expect substantial long-term benefits within the pharmaceutical industry. Enhanced digital integration leads to improved compliance with regulatory standards, increased operational efficiency, and a significant reduction in process errors. Moreover, the increased transparency and communication facilitated by KanBo's features such as card activity streams contribute to a culture of continuous improvement. As digital needs evolve, the adaptability and scalability of KanBo's tools will enable further enhancement of collaboration strategies, securing its role as a crucial asset for any Manufacturing Systems Expert.