Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Maintenance Technician (Electrical) in the Pharmaceutical Industry: Streamlining Collaboration in Complex Technical Environments

What do you need to know about this challenge?

In the pharmaceutical industry, the role of a Maintenance Technician (Electrical) is pivotal in maintaining the functionality and performance of automated systems. These technicians face the complex challenge of ensuring operational efficiency and minimizing downtime. Collaborative efforts are essential in troubleshooting, performing maintenance tasks, and optimizing processes within a multidisciplinary team.

What can you do with KanBo to solve this challenge?

KanBo is equipped with a variety of features that can be leveraged to surmount the collaboration challenges faced by Maintenance Technicians (Electrical). Here’s how:

- Centralized Communication: Utilize the user activity stream to keep all conversations, decisions, and updates in one accessible place, which boosts collaborative problem-solving efforts among maintenance teams.

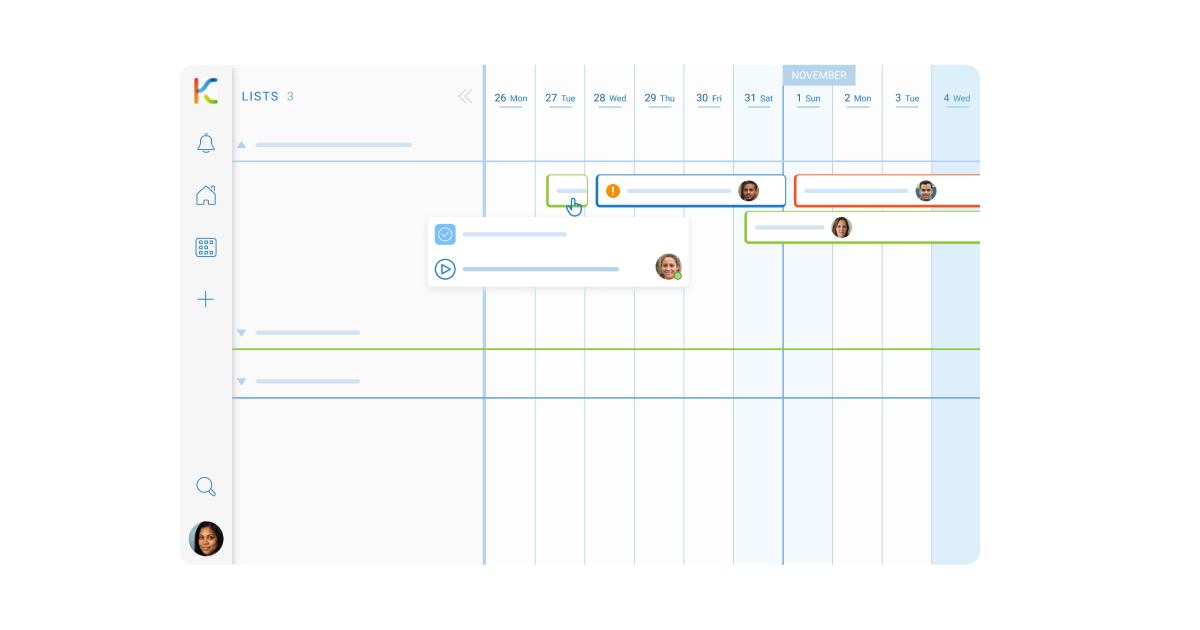

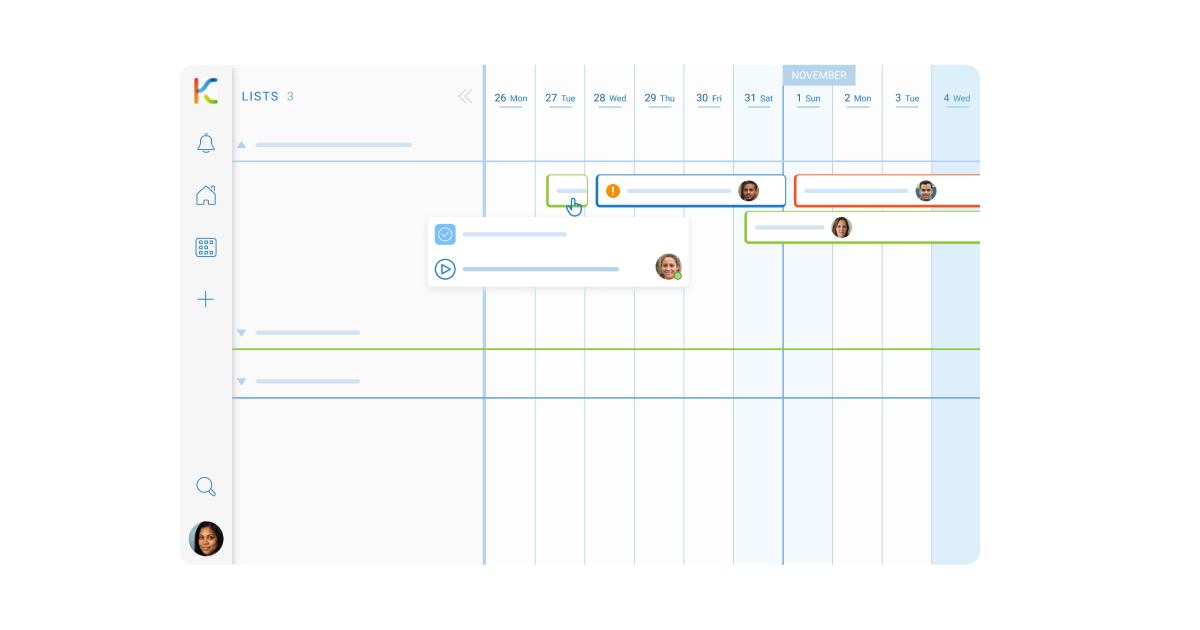

- Scheduling and Planning: Use the Timeline view to align maintenance activities and repairs, avoiding scheduling conflicts while maximizing equipment uptime.

- Task Management: Implement the Kanban view to organize tasks according to their status, streamlining the workflow from diagnosis to resolution in a highly visual format.

- Troubleshooting Tracking: Employ card activity stream to record and track the history of all technical issues, ensuring a comprehensive understanding of maintenance challenges and their solutions.

- Efficient Documentation: Keep essential electrical schematics and technical documents easily accessible through document source integration, simplifying information sharing and reference.

- Organized Task Assessment: Apply filtering cards to quickly sort through and find maintenance tasks or issues, which is crucial in time-sensitive situations.

- Blocked Task Highlighting: Identify and signal any obstacles in the repair or maintenance process by setting card blockers, allowing the team to focus on resolving the issues preventing progress.

What can you expect after solving this challenge?

Following the implementation of KanBo features to tackle the collaboration challenge, Maintenance Technicians (Electrical) in the pharmaceutical industry can expect enhanced operational effectiveness. There will be a sustainable increase in maintenance response times and reduced system downtime, thanks to KanBo's capacity to streamline communication and organize workflows. Long-term, the integration of KanBo's tools into daily operations can lead to better predictive maintenance strategies, increased visibility into recurrent issues, and more strategic resource deployment. The continuous refinement of KanBo’s features will likely boost data-driven decision-making and enable the adoption of more intuitive collaboration practices. Overall, KanBo serves as an indispensable ally in the quest for maintenance excellence.

Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Maintenance Technician (Electrical) in the Pharmaceutical Industry: Streamlining Collaboration in Complex Technical Environments

What do you need to know about this challenge?

In the pharmaceutical industry, the role of a Maintenance Technician (Electrical) is pivotal in maintaining the functionality and performance of automated systems. These technicians face the complex challenge of ensuring operational efficiency and minimizing downtime. Collaborative efforts are essential in troubleshooting, performing maintenance tasks, and optimizing processes within a multidisciplinary team.

What can you do with KanBo to solve this challenge?

KanBo is equipped with a variety of features that can be leveraged to surmount the collaboration challenges faced by Maintenance Technicians (Electrical). Here’s how:

- Centralized Communication: Utilize the user activity stream to keep all conversations, decisions, and updates in one accessible place, which boosts collaborative problem-solving efforts among maintenance teams.

- Scheduling and Planning: Use the Timeline view to align maintenance activities and repairs, avoiding scheduling conflicts while maximizing equipment uptime.

- Task Management: Implement the Kanban view to organize tasks according to their status, streamlining the workflow from diagnosis to resolution in a highly visual format.

- Troubleshooting Tracking: Employ card activity stream to record and track the history of all technical issues, ensuring a comprehensive understanding of maintenance challenges and their solutions.

- Efficient Documentation: Keep essential electrical schematics and technical documents easily accessible through document source integration, simplifying information sharing and reference.

- Organized Task Assessment: Apply filtering cards to quickly sort through and find maintenance tasks or issues, which is crucial in time-sensitive situations.

- Blocked Task Highlighting: Identify and signal any obstacles in the repair or maintenance process by setting card blockers, allowing the team to focus on resolving the issues preventing progress.

What can you expect after solving this challenge?

Following the implementation of KanBo features to tackle the collaboration challenge, Maintenance Technicians (Electrical) in the pharmaceutical industry can expect enhanced operational effectiveness. There will be a sustainable increase in maintenance response times and reduced system downtime, thanks to KanBo's capacity to streamline communication and organize workflows. Long-term, the integration of KanBo's tools into daily operations can lead to better predictive maintenance strategies, increased visibility into recurrent issues, and more strategic resource deployment. The continuous refinement of KanBo’s features will likely boost data-driven decision-making and enable the adoption of more intuitive collaboration practices. Overall, KanBo serves as an indispensable ally in the quest for maintenance excellence.