Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Equipment Specialist (Cell Culture Operator) Pharmaceuticals Collaboration Mastery

What do readers need to know about this challenge?

In the pharmaceutical industry, an Equipment Specialist (Cell Culture Operator) must navigate the intricacies of collaboration within a high-stakes GMP compliant manufacturing setting. The foremost challenge lies in carrying out precise cell culture processes, maintaining sterility, and ensuring comprehensive documentation that meets stringent regulatory requirements.

What can readers do with KanBo to solve this challenge?

- Enhancing Process Coordination: Use the KanBo Card to create a detailed map of all cell culture operations, breaking down the process into clear, manageable tasks and ensuring that every step is transparent and traceable.

- Maintaining Documentation Integrity: With KanBo's Document Source feature, ensure all crucial documents are readily accessible and can be updated by team members in real time, preserving GMP compliance at every stage.

- Real-Time Communication: Employ the User Activity Stream feature to keep team members informed of any actions taken, ensuring that the entire team stays aligned and proactive in their response to any operational changes.

- Proactive Issue Resolution: Utilize Card Blockers to identify and categorize any obstacles in the cell culture process, facilitating swift action to keep the workflow moving smoothly.

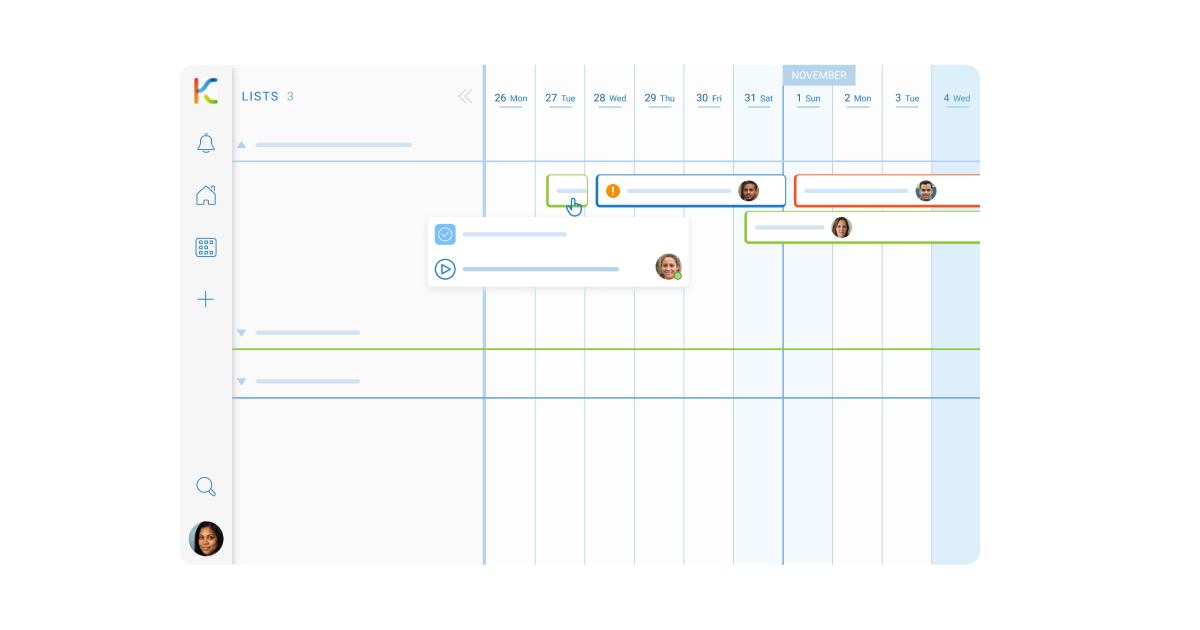

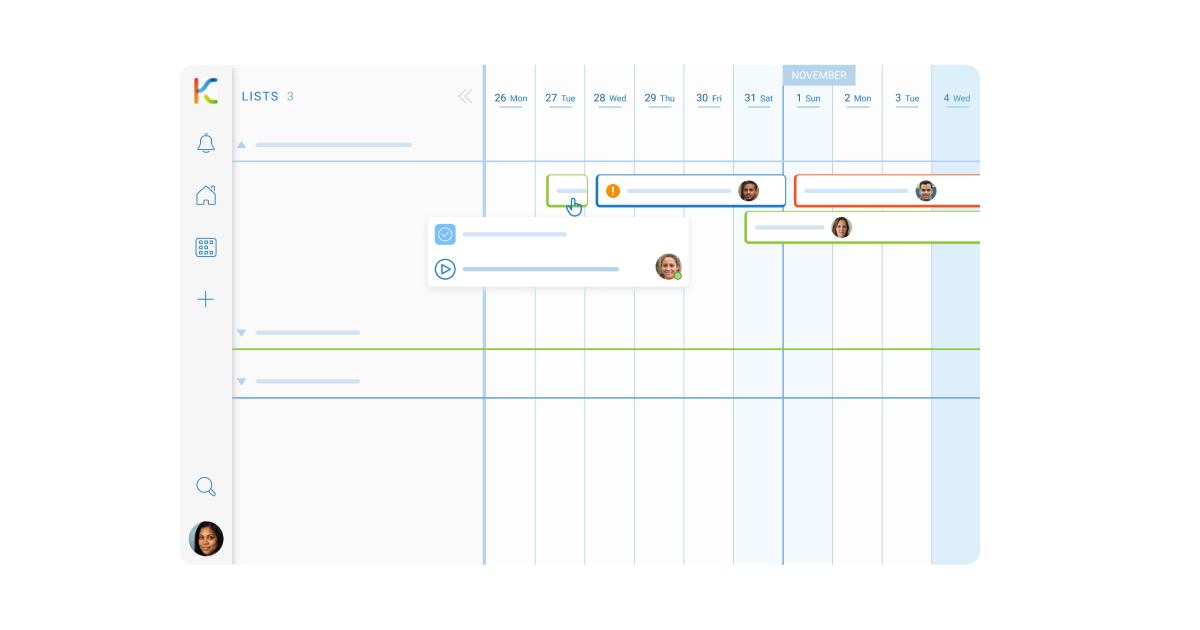

- Scheduling and Forecasting: Leverage the Timeline View to visualize and manage operations schedules, clarifying project timelines and aiding in identifying any potential bottlenecks in advance.

- Effective Task Prioritization: Use Grouping to categorize tasks by their criticality and operational status, ensuring priorities are clear and resources are allocated effectively.

- Seamless Workflow Management: Apply the Gantt Chart View to oversee and adjust the cell culture process workflow, allowing real-time optimization and management of project timelines.

What can readers expect after solving this challenge?

After implementing KanBo as a solution for the collaboration challenge, Equipment Specialists (Cell Culture Operators) in the pharmaceutical industry can expect a fortified production environment where operational transparency and workflow coordination are significantly enhanced. Long-term benefits include a consistent track record of regulatory compliance, a decrease in contamination risks through meticulous process control, and a team that is proficient in using digital tools for real-time collaboration. Future improvements to KanBo might introduce even more sophisticated analytics and AI support, driving proactive problem-solving and predictive scheduling to preemptively address operational concerns, thereby solidifying the role of KanBo as an essential tool for collaboration in this critical field.

Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo Equipment Specialist (Cell Culture Operator) Pharmaceuticals Collaboration Mastery

What do readers need to know about this challenge?

In the pharmaceutical industry, an Equipment Specialist (Cell Culture Operator) must navigate the intricacies of collaboration within a high-stakes GMP compliant manufacturing setting. The foremost challenge lies in carrying out precise cell culture processes, maintaining sterility, and ensuring comprehensive documentation that meets stringent regulatory requirements.

What can readers do with KanBo to solve this challenge?

- Enhancing Process Coordination: Use the KanBo Card to create a detailed map of all cell culture operations, breaking down the process into clear, manageable tasks and ensuring that every step is transparent and traceable.

- Maintaining Documentation Integrity: With KanBo's Document Source feature, ensure all crucial documents are readily accessible and can be updated by team members in real time, preserving GMP compliance at every stage.

- Real-Time Communication: Employ the User Activity Stream feature to keep team members informed of any actions taken, ensuring that the entire team stays aligned and proactive in their response to any operational changes.

- Proactive Issue Resolution: Utilize Card Blockers to identify and categorize any obstacles in the cell culture process, facilitating swift action to keep the workflow moving smoothly.

- Scheduling and Forecasting: Leverage the Timeline View to visualize and manage operations schedules, clarifying project timelines and aiding in identifying any potential bottlenecks in advance.

- Effective Task Prioritization: Use Grouping to categorize tasks by their criticality and operational status, ensuring priorities are clear and resources are allocated effectively.

- Seamless Workflow Management: Apply the Gantt Chart View to oversee and adjust the cell culture process workflow, allowing real-time optimization and management of project timelines.

What can readers expect after solving this challenge?

After implementing KanBo as a solution for the collaboration challenge, Equipment Specialists (Cell Culture Operators) in the pharmaceutical industry can expect a fortified production environment where operational transparency and workflow coordination are significantly enhanced. Long-term benefits include a consistent track record of regulatory compliance, a decrease in contamination risks through meticulous process control, and a team that is proficient in using digital tools for real-time collaboration. Future improvements to KanBo might introduce even more sophisticated analytics and AI support, driving proactive problem-solving and predictive scheduling to preemptively address operational concerns, thereby solidifying the role of KanBo as an essential tool for collaboration in this critical field.