Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo’s Comprehensive Approach to Quality Control Challenges in the Automotive Industry

The Business Challenge:

In the dynamic and demanding environments of automotive manufacturing, maintaining consistent quality in all stages of the production process is a major challenge. This concerns a position such as a CMM Programmer and QC Engineer in Toyota who is responsible for conducting inspections throughout the production process, which includes initial receiving, first article, in-process, and final inspection. They must also implement robust quality control processes and consistently improve quality reporting systems, all whilst navigating a high-pressure, high-volume work environment. Balancing accuracy and thoroughness of inspection with the rapid pace of production creates a complex scenario that needs effective project and process management solutions.

How KanBo Can Help To Overcome The Challenge:

KanBo, a holistic project management and collaboration tool, provides pivotal features that can streamline and simplify these tasks:

- Card: Use KanBo Cards to represent individual components being inspected, each containing pertinent inspection data, notes, and results for clear tracking.

- Document folder: Use Document Folders in Cards to store detailed inspection reports, quality checklists, and component specs related to each unit.

- Space: Create Spaces dedicated to each stage of the inspection, to categorize, and manage the inspection data efficiently.

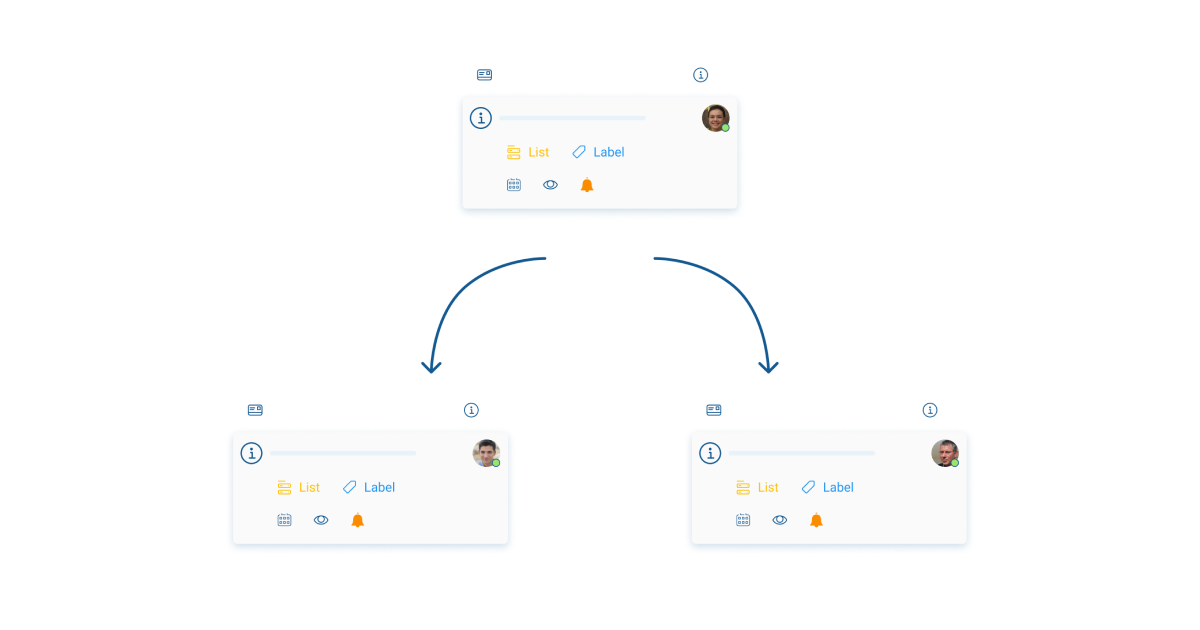

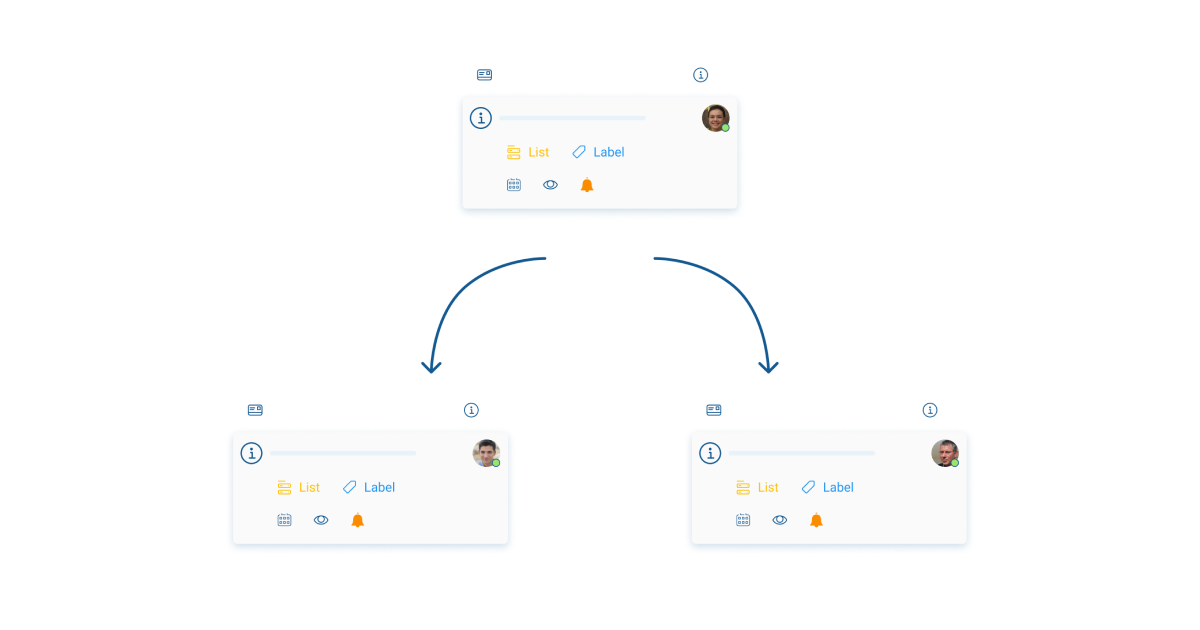

- Card relation: Use Card Relation to create a logical flow of inspection processes as cards move from one inspection stage to the next, creating a clear narrative of progress.

- Activity Streams: Utilize Activity Streams to offer real-time updates and progress, keeping all relevant parties informed and up-to-date throughout the inspection process.

- Reminders: Use Reminders to keep track of inspection schedules and to ensure deadlines are met for every stage of inspection.

- KanBo Search: Utilize KanBo Search feature to quickly locate specific inspection records, quality reports, or component information as needed.

Post-Issue Resolution:

With KanBo in the picture, QC engineers can expect better organization and time-efficiency in the inspection process. The transparent and streamlined nature of communication provided by KanBo bolsters team collaboration, thus reducing the scope of errors and reworks. The detailed activity logs and real-time updates facilitate data-backed decision making, tighter quality control, and continuous improvements in inspection processes.

In the long-run, using KanBo for quality control processes minimizes wastage of resources and promises consistent quality in production, ultimately enhancing customer satisfaction. With future upgrades and integrations, readers can look forward to having intelligent analytics and automated quality notifications for even more precise quality management in their automotive manufacturing endeavors.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo’s Comprehensive Approach to Quality Control Challenges in the Automotive Industry

The Business Challenge:

In the dynamic and demanding environments of automotive manufacturing, maintaining consistent quality in all stages of the production process is a major challenge. This concerns a position such as a CMM Programmer and QC Engineer in Toyota who is responsible for conducting inspections throughout the production process, which includes initial receiving, first article, in-process, and final inspection. They must also implement robust quality control processes and consistently improve quality reporting systems, all whilst navigating a high-pressure, high-volume work environment. Balancing accuracy and thoroughness of inspection with the rapid pace of production creates a complex scenario that needs effective project and process management solutions.

How KanBo Can Help To Overcome The Challenge:

KanBo, a holistic project management and collaboration tool, provides pivotal features that can streamline and simplify these tasks:

- Card: Use KanBo Cards to represent individual components being inspected, each containing pertinent inspection data, notes, and results for clear tracking.

- Document folder: Use Document Folders in Cards to store detailed inspection reports, quality checklists, and component specs related to each unit.

- Space: Create Spaces dedicated to each stage of the inspection, to categorize, and manage the inspection data efficiently.

- Card relation: Use Card Relation to create a logical flow of inspection processes as cards move from one inspection stage to the next, creating a clear narrative of progress.

- Activity Streams: Utilize Activity Streams to offer real-time updates and progress, keeping all relevant parties informed and up-to-date throughout the inspection process.

- Reminders: Use Reminders to keep track of inspection schedules and to ensure deadlines are met for every stage of inspection.

- KanBo Search: Utilize KanBo Search feature to quickly locate specific inspection records, quality reports, or component information as needed.

Post-Issue Resolution:

With KanBo in the picture, QC engineers can expect better organization and time-efficiency in the inspection process. The transparent and streamlined nature of communication provided by KanBo bolsters team collaboration, thus reducing the scope of errors and reworks. The detailed activity logs and real-time updates facilitate data-backed decision making, tighter quality control, and continuous improvements in inspection processes.

In the long-run, using KanBo for quality control processes minimizes wastage of resources and promises consistent quality in production, ultimately enhancing customer satisfaction. With future upgrades and integrations, readers can look forward to having intelligent analytics and automated quality notifications for even more precise quality management in their automotive manufacturing endeavors.