Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Abstract

This document delves into the transformative impacts of Industry 4.0 on the automotive sector, focusing on work coordination mechanisms. It discusses the role of horizontal and vertical digitization, intelligent logistics, risk management, and the integration of cyber-physical systems in establishing the future of the industry. The text also elaborates on the applications of KanBo, a work management platform, that brings about streamlined work processes, thus strengthening the journey towards digital transformation.

Foreword

The digital revolution, cast under the umbrella term of 'Industry 4.0', has permeated countless sectors, perhaps none more profoundly than the automotive industry. This document seeks to explore and elucidate the intricate application of Industry 4.0 principles within the automotive sector, focusing particularly on work coordination. Herein, readers can delve into an in-depth analysis of the changing dynamics of automotive production processes and understand how adopting digital transformation strategies can effectively enhance operational efficiency and productivity.

In the tide of digital transformation washing over the globe, horizontal and vertical digitization in the automotive sector is more than just a catchphrase; it is a crucial driver for enhanced work coordination and efficient process management. Horizontal digitization, with its focus on inter-departmental collaboration, and vertical digitization, aimed at improved process management, are fundamental to the realization of Industry 4.0 in the automotive sector.

The Role of KanBo in Automotive Industry 4.0

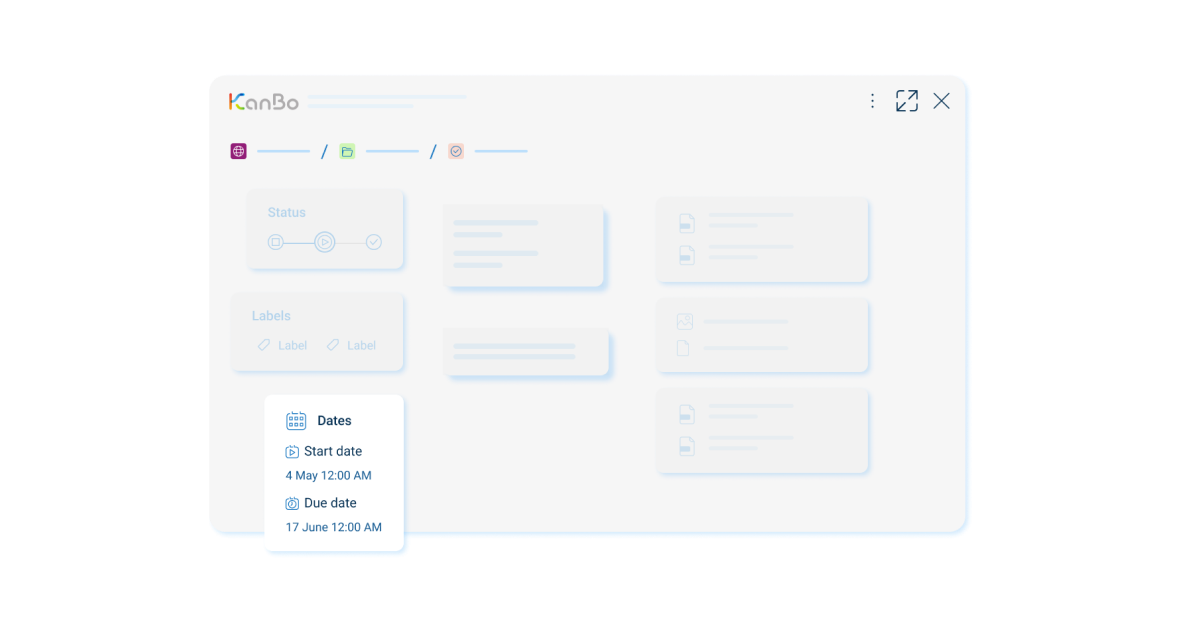

Let's take a look at how KanBo, a versatile, no-training solution, has poised itself as an ally in this journey towards digital restructuring. By streamlining collaboration, KanBo work coordination fits seamlessly into the context of Automotive Industry 4.0. Here are five key ways in which KanBo can guide your organization on the path to a digital future:

- 360-Degree Overview: KanBo's Space provides a holistic picture of ongoing projects, aiding in better decision making and alignment of inter-departmental objectives.

- Real-Time Collaboration: Facilitate instantaneous feedback by creating a common virtual platform for your team, thereby enhancing collaborative work.

- Document Management: KanBo’s document source feature centralizes important project-related information, crucial for efficient teamwork and collaboration in industry 4.

- Project Tracking: Track the progress of individual tasks and the project as a whole with KanBo's built-in tracking and monitoring tools.

- Automated Workflow: Achieve a seamless flow of work by automating and coordinating repetitive tasks.

Unleashing the potential of smart factories and a digitally competent workforce will require combining technology with a robust coordination strategy. Use these tips to augment your automotive industry 4.0 journey:

- Democratize Data Access: Encourage transparency by granting appropriate departmental access to necessary data.

- Promote Cross-Functional Collaboration: Foster an environment conducive to collaborative work and creative problem-solving.

- Embrace Automation: Seek out platforms and solutions that will help streamline your workflows and reduce redundancy.

- Prioritize Training: Ensure your workforce is well-equipped to handle the transition to a workplace collaborative digital ecosystem.

- Continuous Improvement: Regularly seek feedback and actively make improvements to adapt and evolve on your digital journey.

At the intersection of digital transformation and the automotive industry, teamwork and collaboration bolstered by tools like KanBo, not only enhance work coordination but also usher in a new era of smart factories and enhanced productivity. This comprehensive guide serves as a stepping stone on your path to a digitally empowered, collaborative future in Automotive Industry 4.0.

Networking the Future: The Advent of 360-Degree Networking in Industry 4.0

With the digital transformation of the automotive industry brewing towards Industry 4.0, a paramount pillar that has ascended to the forefront is 360-degree networking. It becomes the axle around which the wheel of work coordination rotates, connecting various facets of the manufacturing process to enhance operational fluidity and encourage seamless collaboration.

360-degree networking in Industry 4.0 context discusses the unison of multiple departments and teams throughout the length and breadth of the manufacturing sector. It is akin to an invisible yet robust yarn interweaving different threads to weave a sturdy fabric of an efficient workflow.

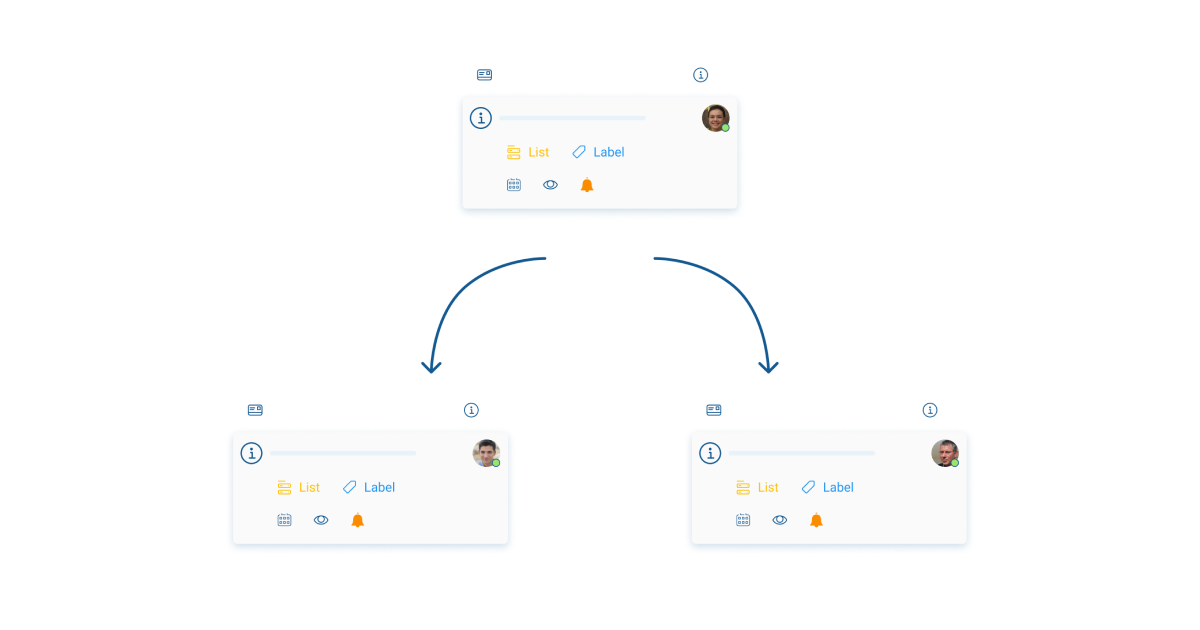

An adaptable tool like the KanBo platform can tremendously streamline this process. As a versatile and no-training solution, KanBo offers effortless coordination, which is crucial for organizations' shareholders looking to maximize productivity. For example, through precise task management features, project timelines, and real-time communication tools, stakeholders can maintain optimal workflow and visibility across all departments.

In the backdrop of the digital transformation, six easy-to-adopt tips using KanBo can enhance inter-departmental collaboration and thus, work coordination:

Use the ‘Activity Stream’ feature to analyze work patterns and bottlenecks

Implement ‘Card’ in ‘Space’ features to assign, track, and manage tasks throughout different teams

Utilize the ‘Chat’ feature to facilitate real-time collaboration and discussion

Leverage the ‘Calendar View’ to manage schedules across all departments

Utilize the ‘Document Source’ feature to centralize project-related documents

Use the 'Search Filters' and 'Search Sorting' to quickly find and organize information.

Integrating Safety & Security are intrinsic to this seamless networking

Let's break down the implementation of Industry 4.0 into five pivotal levels:

1. Level - Basic Digitization

Here, the company hasn't fully embraced Industry 4.0, with requirements either unmet or partially fulfilled.

2. Level - Inter-Department Digitization

At this level, the company actively pursues Industry 4.0. Digitization is implemented across various departments, laying the foundation for a fully integrated digital system.

3. Level - Horizontal and Vertical Digitization

This level implies complete digitization across the company, including information flows, and signals the full implementation of Industry 4.0 requirements.

4. Level - Full Digitization

At this level, the company has been entirely digitized beyond enterprise limits and integrated into value networks.

5. Level - Optimized Full Digitization

This level represents a standard-bearer for Industry 4.0. The company collaborates with its business partners, optimizing its value networks and making it fully future-ready.

Embedded within these evolutionary stages of digitization, platforms like KanBo play a pivotal role in enabling businesses to transition smoothly across these levels. With the right combination of digital tools and strategic foresight, automotive industry players can gear up to embrace the full spectrum of Industry 4.0 and achieve collaborative excellence within their organizations.

Autonomous Machines & Humans: Steering the Future of Automotive Industry

In a world where industrial processes are increasingly automated, the automotive industry is leading the charge. One of the most significant shifts in this landscape is the emergence of autonomous robots and machines as collaborative partners for humans. The integration of these technologies into the production environment is revolutionizing the way work coordination is perceived and executed, subsequently steering the industry towards Automotive Industry 4.0.

Autonomous robots are capable of performing complex tasks with precision and speed, making them invaluable assets on the shop floor. From assembling car parts to assisting in quality control and managing inventory, these robots enhance operational efficiency while reducing errors.

However, the key to unlocking the full potential of these autonomous machines lies in the effective coordination of processes between humans and machines. Accomplishing this requires a versatile and no-training solution that aids in creating a constructive human-machine-human communication model, and that's where KanBo technology steps in.

KanBo, a comprehensive work management and collaboration platform, can act as a pivotal tool for work coordination in an environment teeming with advanced machines. It enables the management of tasks, tracking of project progress, and enhances team collaboration, thereby fostering an environment of optimized production.

Here are some tips on how KanBo can be utilized for effective work coordination in Automotive Industry 4.0 context

Top 5 tips for effective work coordination:

1. Create and assign tasks for autonomous robots directly from the KanBo.

2. Track the progress and status of tasks executed by machines in real-time.

3. Enable seamless communication between team members and robots through KanBo’s integrated messaging and notification features.

4. Leverage the document management capabilities of KanBo to maintain machine manuals, guidelines, and related documents for quick accessibility.

5. Make use of KanBo's rich integration possibilities, including with Outlook, Microsoft Teams, SharePoint Document Libraries, Microsoft Power Automate, and others, to centralize and streamline communications, documents, processes, and workflows.

As a forward-looking step, employing rich integrations from KanBo can foster seamless, real-time communication between humans and machines. For example, by integrating the KanBo platform with a machine’s operational system, alerts, updates, and instructions can be instantly shared between the machine and a human operator or analyst. This not only optimises the production process, but also creates a digital feedback loop, an essential component of the digital transformation success.

The 'Smart Factory' Revolution: Streamlining Work Coordination in Automotive Industry 4.0

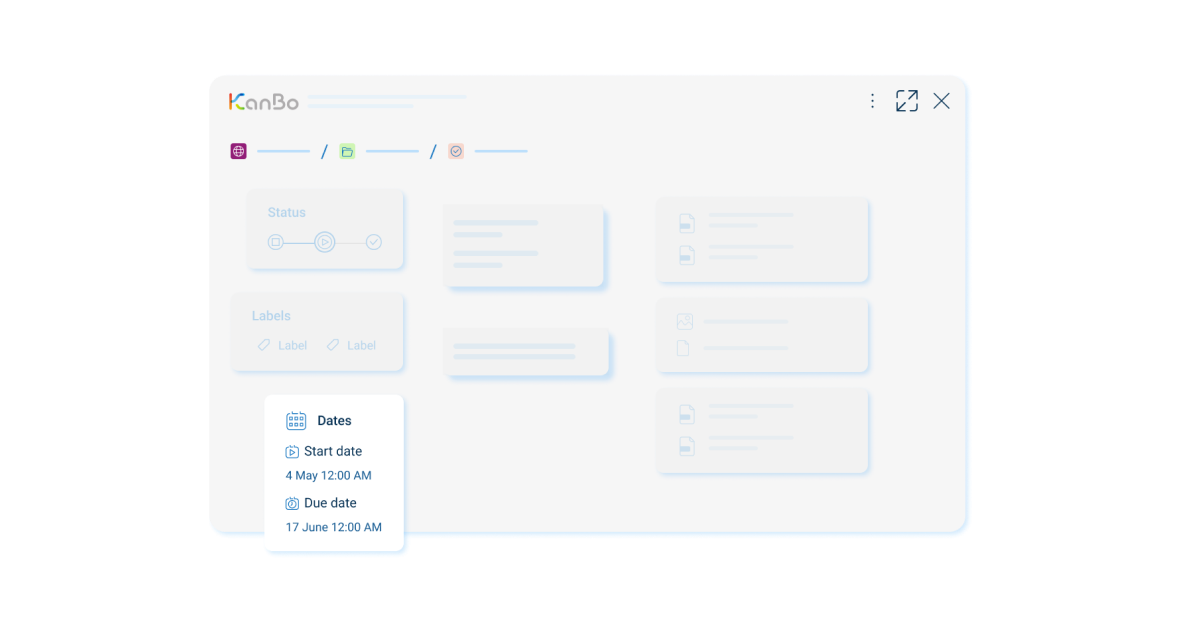

Industry 4.0 has literally brought about a revolution in the automotive industry, especially with the introduction of the concept of 'Smart Factory.' Underpinned by digital transformation, a 'Smart Factory' is an advanced form of manufacturing setup where everything is connected. Automotive 4.0 and the smart factory concepts have changed the game by introducing digital twins that can dramatically streamline work coordination.

A 'Digital Twin' is essentially a digital duplicate of the physical manufacturing process. It provides real-time visibility into processes, systems, and an entire production facility, thus supercharging operational efficiency and productivity. The enhanced visibility also ensures that teams across the organization are always aware of production statuses and potential bottlenecks. In addition, it allows organizations to simulate different scenarios and accurately predict outputs and process optimization without disrupting ongoing operations – a complete game-changer in terms of collaborative work and coordination.

KanBo, a comprehensive digital platform, is primed to support organizations in this transition towards smart factories. The platform is built to bridge the gaps in coordination, ensuring seamless teamwork and collaboration. Since its features mirror the characteristics of Industry 4.0, it allows for real-time task and project management, information sharing, advanced search functionalities, and much more.

As an expert advises, here are top ways to use KanBo to propel your organization's journey towards Automotive Industry 4.0

5 Top way to use KanBo:

1. Utilize KanBo's digital space feature to visually manage work processes in real-time. This encourages improved coordination among team members and provides a clear view of ongoing tasks

2. Enable the 'Card Relations' feature for managing complex tasks. This allows you to break down large tasks into smaller, manageable ones, promoting comprehensive work understanding, transparency, and better collaboration.

3. Use KanBo's task assignment and deadlines features to create a highly coordinated and time-efficient workflow.

4. KanBo's advanced Search Filters can be used to rapidly locate files, tasks, or team members' inputs, significantly improving work coordination.

5. Utilize the document management capability to create, store, share, and retrieve critical documents in real-time, thereby enhancing collaborative work.

The integration of KanBo in the automotive industry is indeed a game-changing move, contributing to enhanced workplace collaborative and coordination, thereby paving the way for the successful realization of Industry 4.0 and Smart factories. It's not only a tactful approach for organizations to embrace digital transformation but also an adaptable, intuitive solution for all stakeholders. Hence, KanBo and Automotive Industry 4.0 go hand in hand, driving synergistic efficiency and growth.

Intelligent Logistics: The Fuel for Efficiency and Customer Satisfaction in Automotive Industry 4.0

Logistics in the world of automotive industry 4.0 has taken a quantum leap with the advent of intelligent logistics systems. These systems leverage the power of real-time data, predictive analytics, and cyber-physical systems, making them a vital cog in the wheel of work coordination mechanism.

Intelligent Logistics systems significantly bridge the gap between the customers and manufacturers, commencing right from the intricate process of vehicle configuration to the multi-faceted stages of manufacturing, and ultimately, its timely shipping. The customer takes the driver’s seat, customizing their vehicle configurations as per their preferences. This is where intelligent logistics steps in, coordinating the information flow seamlessly into the manufacturing unit, gathering necessary components, and activating the needed manufacturing processes.

Integrating digital technologies into the logistics realm induces robust transformation, allowing automotive manufacturers to align their production schedules closer to market demands, thus ensuring efficient production and delivery. The automotive industry is complex and is integrated with numerous suppliers and partners. An intelligent logistics system can optimally manage inventory, track and trace components, manage warehousing and transport resources, hence effectively coordinating production and supply-chain operations in the field of automotive industry 4.0.

A platform like KanBo can significantly aid this process of work coordination within intelligent logistics. Recognized for its proficiency as a work coordination platform, KanBo offers a comprehensive suite that enables organizations to streamline their work processes and enhances collaborative efforts in an IoT-enabled ecosystem.

Here are some ways how KanBo can accelerate work coordination in intelligent logistics within the automotive sector

1. Real-Time Monitoring

With KanBo’s feature to create and manage tasks in real-time, organizations can effortlessly track the progress of logistics operations, right from procurement, warehousing till shipping.

2. Document Collaboration

Storing and managing documents related with logistics operations becomes easier with KanBo, ensuring that everyone is aligned with the latest information.

3. Enhanced Communication

The seamless communication on KanBo’s platform means that any changes in orders or configurations can be quickly communicated across teams, ensuring a smooth logistical operation.

4. Risk Management

Using KanBo’s card feature, organizations can assign risk levels to specific operations, ensuring that every process within the logistics chain is monitored and controlled effectively.

Intelligent logistics has become a cornerstone in the pursuit of digital transformation in the automotive industry 4.0. An effective work coordination platform like KanBo can significantly amplify the benefits of intelligent logistics, fostering an environment of workplace collaboration and efficiency in smart factories. The emphasis now, more than ever, is on teamwork and collaboration in Industry 4.0, and this is where KanBo shines, making every facet of work coordination in the automotive industry more seamless and effective.

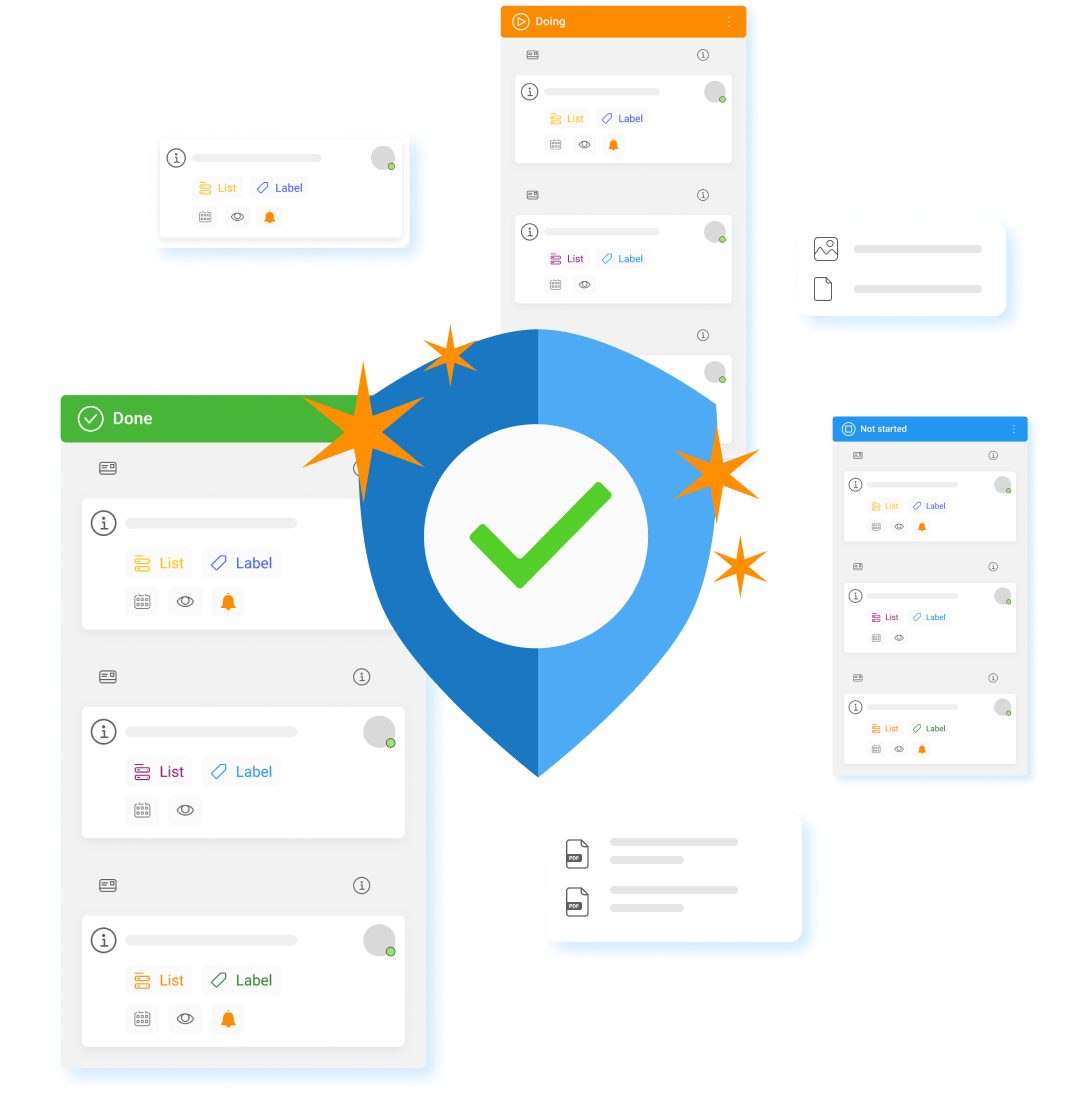

Risk Management in Automotive Industry 4.0: The Importance of Mediating Emerging Risks

Automotive Industry 4.0 has brought forth a massive revolution, with digital transformation and smart factories becoming the new norms. This paradigm shift has, however, brought about new forms of risk in their wake. These threats, which range from cybersecurity issues to process failures, necessitate secure and strategic risk management.

KanBo, a leading platform in project and process management, has surfaced as an essential tool in the automotive industry, assisting work coordination efforts, and fostering collaborative work. Its versatility spans offering a comprehensive view of project processes, promoting seamless teamwork and collaboration, and mitigating potential risks.

KanBo's exceptional Card Blockers feature is instrumental in risk management within Industry 4.0. This dedicated feature enables users to identify and manage potential impediments proactively. Users can create several card blockers to pinpoint standstill reasons explicitly, leading to a clear categorization of problematic work.

A range of card blockers can be utilized depending upon the degree of visibility required. Local blockers are confined to one space, utility perfect for smaller teams, and allow in-space users to be apprised about the blocker. Global and on-demand blockers, however, offer a higher level of visibility and can be monitored from a wider perspective; this proves to be beneficial for larger, more complex project environments.

These features equip stakeholders with necessary visibility into potential roadblocks, facilitating the activation of remedial measures promptly. For instance, a card cannot change its status while it's blocked, signaling a clear pause in the process flow. This smart mechanism ensures that potential issues are tackled before progressing further into the workflow.

The pivotal notion is - RISKS in Industry 4.0

Risks can be proactively managed with an effective work coordination solution like KanBo, to ensure a smooth implementation.

4 tips for effective Risks management with KanBo

1. Maintain clear communication

Keep team members updated on the status of tasks, blockers, and remedial steps taken. Transparency fosters collaboration and swift rectification of issues.

2. Utilize KanBo's Card Blockers wisely

Card blockers are powerful tools for flagging and managing risks. Use different blockers for different scenarios and monitor them using My Blockers, conveniently located on the Navigation Panel.

3. Leverage 360-degree networking

Link teams together for real-time communication and collaboration. Feedback is instantaneous, and problem-solving becomes a quicker, more efficient process.

4. Reinforce cybersecurity

As collaboration moves onto digital platforms, reinforce your team's awareness about cybersecurity and secure coding practices to mitigate related risks.

The digital transformation in the automotive industry, characterized by the shift to Industry 4.0, has necessitated a rethink of work coordination strategies. For sustaining growth in this dynamics, a tool as comprehensive and sophisticated as KanBo becomes paramount. It allows teams to embrace an interconnected digitalized work environment, create smart factories, and leverage industry 4.0's strengths while simultaneously managing its inherent risks. A strategic approach to risk management, backed by KanBo's robust features, will be a significant driving force in the journey towards a safe, digitally-enabled Automotive Industry 4.0.

Automotive Industry 4.0: Strategies and Implementation

Automotive companies are strategically positioning themselves to meet the challenges and opportunities of Automotive 4.0. Key trends in their approach include automation, data analytics, robotics, artificial intelligence, and connected networks. These strategies are designed to enhance productivity, reduce costs, and improve customer satisfaction by delivering highly customized and quick solutions.

1. Automation and Digital Transformation 1

Companies like Volkswagen and Renault Group are investing significantly in automation technologies. Complex tasks, such as the installation of headliners in vehicles, are now being carried out by robots in some plants. The testing and implementation of automation technologies are conducted during active production periods, hence merging real-world experiences with high-tech solutions.

2. Data Analytics 2

Real-time supply management is a crucial aspect of Industry 4.0 for automotive companies. As soon as customer orders are received, suppliers are informed, raw materials are prepared, and logistics chains are established. Industry 4.0 is about complete transparency and the ability to manage data in real-time. For example, Mercedes-Benz is working with Google Cloud to create industrial solutions based on shared knowledge and expertise.

3. Robotics and Artificial Intelligence 3

Companies are leveraging technology to create a collaborative environment where humans and robots can work together in the production process. Teams comprising of people and cobots (collaborative robots) are becoming commonplace. Cobots provide heavy lifting, while humans provide expertise, therefore improving workers' environments, and enhancing productivity.

4. Connected Networks 4

The automotive industry 4.0 aims to build connected networks encompassing suppliers, employees, machines, and the products themselves. Each product is tracked from the assembly line to delivery, ensuring continuous traceability. This helps customers follow their orders in real-time and guarantees quality control.

5. Virtual Reality 5

Automotive companies are using VR for training operators, visualizing production lines, and optimizing workstation layouts. VR is transforming the learning process and providing safe and efficient methods to learn new techniques.

Final Summary

The future of the automotive industry lies within the realm of Industry 4.0, where digital transformation shapes every facet of work coordination. This integration requires the harmonization of diverse elements – from evolving communication platforms to improved data management strategies and risk mitigation tactics. The incorporation of KanBo as a project and process management tool stands out as a transformative player central to these endeavours. The objective that remains constant throughout this evolutionary journey is the need to enhance productivity, efficiency, and drive innovation while prioritizing safety and risk management.

About article

In conclusion, the coordination of work in the context of Automotive 4.0 and Industry 4.0 is a complex and constantly evolving process. This article, written by a team of contributors with extensive knowledge and experience, provides an in-depth exploration of the topic. By drawing on information from leading automotive companies such as VW, Renault, and Mercedes Benz, as well as the research conducted by Juraj Sinay and Zuzana Kotianová, this article sheds light on the emerging trends and challenges in the automotive industry. The implementation of Industry 4.0 principles, including the integration of cyber-physical systems, sensor technologies, and intelligent data management, has become crucial for automotive businesses to adapt to the changing landscape and maintain their competitiveness. With the ongoing development of technologies and the increasing automation of processes, it is essential for companies to prioritize safety measures and risk management. By embracing the principles of Industry 4.0, the automotive industry will continue to drive innovation and economic growth while ensuring the safety and efficiency of its operations.

Links and resources

- https://www.renaultgroup.com/en/innovation-2/industry-4-0-production-plants-shaped-by-the-future/

- https://group.mercedes-benz.com/innovation/case/connectivity/industry-4-0.html

- https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-40-the-production-systems-of-tomorrow-are-being-developed-in-the-glaeserne-manufaktur-in-dresden-4753

- https://www.researchgate.net/publication/331507570_Automotive_Industry_in_the_Context_of_Industry_40_Strategy

- https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-digital-twin-technology

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Abstract

This document delves into the transformative impacts of Industry 4.0 on the automotive sector, focusing on work coordination mechanisms. It discusses the role of horizontal and vertical digitization, intelligent logistics, risk management, and the integration of cyber-physical systems in establishing the future of the industry. The text also elaborates on the applications of KanBo, a work management platform, that brings about streamlined work processes, thus strengthening the journey towards digital transformation.

Foreword

The digital revolution, cast under the umbrella term of 'Industry 4.0', has permeated countless sectors, perhaps none more profoundly than the automotive industry. This document seeks to explore and elucidate the intricate application of Industry 4.0 principles within the automotive sector, focusing particularly on work coordination. Herein, readers can delve into an in-depth analysis of the changing dynamics of automotive production processes and understand how adopting digital transformation strategies can effectively enhance operational efficiency and productivity.

In the tide of digital transformation washing over the globe, horizontal and vertical digitization in the automotive sector is more than just a catchphrase; it is a crucial driver for enhanced work coordination and efficient process management. Horizontal digitization, with its focus on inter-departmental collaboration, and vertical digitization, aimed at improved process management, are fundamental to the realization of Industry 4.0 in the automotive sector.

The Role of KanBo in Automotive Industry 4.0

Let's take a look at how KanBo, a versatile, no-training solution, has poised itself as an ally in this journey towards digital restructuring. By streamlining collaboration, KanBo work coordination fits seamlessly into the context of Automotive Industry 4.0. Here are five key ways in which KanBo can guide your organization on the path to a digital future:

- 360-Degree Overview: KanBo's Space provides a holistic picture of ongoing projects, aiding in better decision making and alignment of inter-departmental objectives.

- Real-Time Collaboration: Facilitate instantaneous feedback by creating a common virtual platform for your team, thereby enhancing collaborative work.

- Document Management: KanBo’s document source feature centralizes important project-related information, crucial for efficient teamwork and collaboration in industry 4.

- Project Tracking: Track the progress of individual tasks and the project as a whole with KanBo's built-in tracking and monitoring tools.

- Automated Workflow: Achieve a seamless flow of work by automating and coordinating repetitive tasks.

Unleashing the potential of smart factories and a digitally competent workforce will require combining technology with a robust coordination strategy. Use these tips to augment your automotive industry 4.0 journey:

- Democratize Data Access: Encourage transparency by granting appropriate departmental access to necessary data.

- Promote Cross-Functional Collaboration: Foster an environment conducive to collaborative work and creative problem-solving.

- Embrace Automation: Seek out platforms and solutions that will help streamline your workflows and reduce redundancy.

- Prioritize Training: Ensure your workforce is well-equipped to handle the transition to a workplace collaborative digital ecosystem.

- Continuous Improvement: Regularly seek feedback and actively make improvements to adapt and evolve on your digital journey.

At the intersection of digital transformation and the automotive industry, teamwork and collaboration bolstered by tools like KanBo, not only enhance work coordination but also usher in a new era of smart factories and enhanced productivity. This comprehensive guide serves as a stepping stone on your path to a digitally empowered, collaborative future in Automotive Industry 4.0.

Networking the Future: The Advent of 360-Degree Networking in Industry 4.0

With the digital transformation of the automotive industry brewing towards Industry 4.0, a paramount pillar that has ascended to the forefront is 360-degree networking. It becomes the axle around which the wheel of work coordination rotates, connecting various facets of the manufacturing process to enhance operational fluidity and encourage seamless collaboration.

360-degree networking in Industry 4.0 context discusses the unison of multiple departments and teams throughout the length and breadth of the manufacturing sector. It is akin to an invisible yet robust yarn interweaving different threads to weave a sturdy fabric of an efficient workflow.

An adaptable tool like the KanBo platform can tremendously streamline this process. As a versatile and no-training solution, KanBo offers effortless coordination, which is crucial for organizations' shareholders looking to maximize productivity. For example, through precise task management features, project timelines, and real-time communication tools, stakeholders can maintain optimal workflow and visibility across all departments.

In the backdrop of the digital transformation, six easy-to-adopt tips using KanBo can enhance inter-departmental collaboration and thus, work coordination:

Use the ‘Activity Stream’ feature to analyze work patterns and bottlenecks

Implement ‘Card’ in ‘Space’ features to assign, track, and manage tasks throughout different teams

Utilize the ‘Chat’ feature to facilitate real-time collaboration and discussion

Leverage the ‘Calendar View’ to manage schedules across all departments

Utilize the ‘Document Source’ feature to centralize project-related documents

Use the 'Search Filters' and 'Search Sorting' to quickly find and organize information

Integrating Safety & Security are intrinsic to this seamless networking

Let's break down the implementation of Industry 4.0 into five pivotal levels:

1. Level - Basic Digitization

Here, the company hasn't fully embraced Industry 4.0, with requirements either unmet or partially fulfilled.

2. Level - Inter-Department Digitization

At this level, the company actively pursues Industry 4.0. Digitization is implemented across various departments, laying the foundation for a fully integrated digital system.

3. Level - Horizontal and Vertical Digitization

This level implies complete digitization across the company, including information flows, and signals the full implementation of Industry 4.0 requirements.

4. Level - Full Digitization

At this level, the company has been entirely digitized beyond enterprise limits and integrated into value networks.

5. Level - Optimized Full Digitization

This level represents a standard-bearer for Industry 4.0. The company collaborates with its business partners, optimizing its value networks and making it fully future-ready.

Embedded within these evolutionary stages of digitization, platforms like KanBo play a pivotal role in enabling businesses to transition smoothly across these levels. With the right combination of digital tools and strategic foresight, automotive industry players can gear up to embrace the full spectrum of Industry 4.0 and achieve collaborative excellence within their organizations.

Autonomous Machines & Humans: Steering the Future of Automotive Industry

In a world where industrial processes are increasingly automated, the automotive industry is leading the charge. One of the most significant shifts in this landscape is the emergence of autonomous robots and machines as collaborative partners for humans. The integration of these technologies into the production environment is revolutionizing the way work coordination is perceived and executed, subsequently steering the industry towards Automotive Industry 4.0.

Autonomous robots are capable of performing complex tasks with precision and speed, making them invaluable assets on the shop floor. From assembling car parts to assisting in quality control and managing inventory, these robots enhance operational efficiency while reducing errors.

However, the key to unlocking the full potential of these autonomous machines lies in the effective coordination of processes between humans and machines. Accomplishing this requires a versatile and no-training solution that aids in creating a constructive human-machine-human communication model, and that's where KanBo technology steps in.

KanBo, a comprehensive work management and collaboration platform, can act as a pivotal tool for work coordination in an environment teeming with advanced machines. It enables the management of tasks, tracking of project progress, and enhances team collaboration, thereby fostering an environment of optimized production.

Here are some tips on how KanBo can be utilized for effective work coordination in Automotive Industry 4.0 context

Top 5 tips for effective work coordination:

1. Create and assign tasks for autonomous robots directly from the KanBo.

2. Track the progress and status of tasks executed by machines in real-time.

3. Enable seamless communication between team members and robots through KanBo’s integrated messaging and notification features.

4. Leverage the document management capabilities of KanBo to maintain machine manuals, guidelines, and related documents for quick accessibility.

5. Make use of KanBo's rich integration possibilities, including with Outlook, Microsoft Teams, SharePoint Document Libraries, Microsoft Power Automate, and others, to centralize and streamline communications, documents, processes, and workflows.

As a forward-looking step, employing rich integrations from KanBo can foster seamless, real-time communication between humans and machines. For example, by integrating the KanBo platform with a machine’s operational system, alerts, updates, and instructions can be instantly shared between the machine and a human operator or analyst. This not only optimises the production process, but also creates a digital feedback loop, an essential component of the digital transformation success.

The 'Smart Factory' Revolution: Streamlining Work Coordination in Automotive Industry 4.0

Industry 4.0 has literally brought about a revolution in the automotive industry, especially with the introduction of the concept of 'Smart Factory.' Underpinned by digital transformation, a 'Smart Factory' is an advanced form of manufacturing setup where everything is connected. Automotive 4.0 and the smart factory concepts have changed the game by introducing digital twins that can dramatically streamline work coordination.

A 'Digital Twin' is essentially a digital duplicate of the physical manufacturing process. It provides real-time visibility into processes, systems, and an entire production facility, thus supercharging operational efficiency and productivity. The enhanced visibility also ensures that teams across the organization are always aware of production statuses and potential bottlenecks. In addition, it allows organizations to simulate different scenarios and accurately predict outputs and process optimization without disrupting ongoing operations – a complete game-changer in terms of collaborative work and coordination.

KanBo, a comprehensive digital platform, is primed to support organizations in this transition towards smart factories. The platform is built to bridge the gaps in coordination, ensuring seamless teamwork and collaboration. Since its features mirror the characteristics of Industry 4.0, it allows for real-time task and project management, information sharing, advanced search functionalities, and much more.

As an expert advises, here are top ways to use KanBo to propel your organization's journey towards Automotive Industry 4.0

5 Top way to use KanBo:

1. Utilize KanBo's digital space feature to visually manage work processes in real-time. This encourages improved coordination among team members and provides a clear view of ongoing tasks

2. Enable the 'Card Relations' feature for managing complex tasks. This allows you to break down large tasks into smaller, manageable ones, promoting comprehensive work understanding, transparency, and better collaboration.

3. Use KanBo's task assignment and deadlines features to create a highly coordinated and time-efficient workflow.

4. KanBo's advanced Search Filters can be used to rapidly locate files, tasks, or team members' inputs, significantly improving work coordination.

5. Utilize the document management capability to create, store, share, and retrieve critical documents in real-time, thereby enhancing collaborative work.

The integration of KanBo in the automotive industry is indeed a game-changing move, contributing to enhanced workplace collaborative and coordination, thereby paving the way for the successful realization of Industry 4.0 and Smart factories. It's not only a tactful approach for organizations to embrace digital transformation but also an adaptable, intuitive solution for all stakeholders. Hence, KanBo and Automotive Industry 4.0 go hand in hand, driving synergistic efficiency and growth.

Intelligent Logistics: The Fuel for Efficiency and Customer Satisfaction in Automotive Industry 4.0

Logistics in the world of automotive industry 4.0 has taken a quantum leap with the advent of intelligent logistics systems. These systems leverage the power of real-time data, predictive analytics, and cyber-physical systems, making them a vital cog in the wheel of work coordination mechanism.

Intelligent Logistics systems significantly bridge the gap between the customers and manufacturers, commencing right from the intricate process of vehicle configuration to the multi-faceted stages of manufacturing, and ultimately, its timely shipping. The customer takes the driver’s seat, customizing their vehicle configurations as per their preferences. This is where intelligent logistics steps in, coordinating the information flow seamlessly into the manufacturing unit, gathering necessary components, and activating the needed manufacturing processes.

Integrating digital technologies into the logistics realm induces robust transformation, allowing automotive manufacturers to align their production schedules closer to market demands, thus ensuring efficient production and delivery. The automotive industry is complex and is integrated with numerous suppliers and partners. An intelligent logistics system can optimally manage inventory, track and trace components, manage warehousing and transport resources, hence effectively coordinating production and supply-chain operations in the field of automotive industry 4.0.

A platform like KanBo can significantly aid this process of work coordination within intelligent logistics. Recognized for its proficiency as a work coordination platform, KanBo offers a comprehensive suite that enables organizations to streamline their work processes and enhances collaborative efforts in an IoT-enabled ecosystem.

Here are some ways how KanBo can accelerate work coordination in intelligent logistics within the automotive sector

1. Real-Time Monitoring

With KanBo’s feature to create and manage tasks in real-time, organizations can effortlessly track the progress of logistics operations, right from procurement, warehousing till shipping.

2. Document Collaboration

Storing and managing documents related with logistics operations becomes easier with KanBo, ensuring that everyone is aligned with the latest information.

3. Enhanced Communication

The seamless communication on KanBo’s platform means that any changes in orders or configurations can be quickly communicated across teams, ensuring a smooth logistical operation.

4. Risk Management

Using KanBo’s card feature, organizations can assign risk levels to specific operations, ensuring that every process within the logistics chain is monitored and controlled effectively.

Intelligent logistics has become a cornerstone in the pursuit of digital transformation in the automotive industry 4.0. An effective work coordination platform like KanBo can significantly amplify the benefits of intelligent logistics, fostering an environment of workplace collaboration and efficiency in smart factories. The emphasis now, more than ever, is on teamwork and collaboration in Industry 4.0, and this is where KanBo shines, making every facet of work coordination in the automotive industry more seamless and effective.

Risk Management in Automotive Industry 4.0: The Importance of Mediating Emerging Risks

Automotive Industry 4.0 has brought forth a massive revolution, with digital transformation and smart factories becoming the new norms. This paradigm shift has, however, brought about new forms of risk in their wake. These threats, which range from cybersecurity issues to process failures, necessitate secure and strategic risk management.

KanBo, a leading platform in project and process management, has surfaced as an essential tool in the automotive industry, assisting work coordination efforts, and fostering collaborative work. Its versatility spans offering a comprehensive view of project processes, promoting seamless teamwork and collaboration, and mitigating potential risks.

KanBo's exceptional Card Blockers feature is instrumental in risk management within Industry 4.0. This dedicated feature enables users to identify and manage potential impediments proactively. Users can create several card blockers to pinpoint standstill reasons explicitly, leading to a clear categorization of problematic work.

A range of card blockers can be utilized depending upon the degree of visibility required. Local blockers are confined to one space, utility perfect for smaller teams, and allow in-space users to be apprised about the blocker. Global and on-demand blockers, however, offer a higher level of visibility and can be monitored from a wider perspective; this proves to be beneficial for larger, more complex project environments.

These features equip stakeholders with necessary visibility into potential roadblocks, facilitating the activation of remedial measures promptly. For instance, a card cannot change its status while it's blocked, signaling a clear pause in the process flow. This smart mechanism ensures that potential issues are tackled before progressing further into the workflow.

The pivotal notion is - RISKS in Industry 4.0

Risks can be proactively managed with an effective work coordination solution like KanBo, to ensure a smooth implementation.

4 tips for effective Risks management with KanBo

1. Maintain clear communication

Keep team members updated on the status of tasks, blockers, and remedial steps taken. Transparency fosters collaboration and swift rectification of issues.

2. Utilize KanBo's Card Blockers wisely

Card blockers are powerful tools for flagging and managing risks. Use different blockers for different scenarios and monitor them using My Blockers, conveniently located on the Navigation Panel.

3. Leverage 360-degree networking

Link teams together for real-time communication and collaboration. Feedback is instantaneous, and problem-solving becomes a quicker, more efficient process.

4. Reinforce cybersecurity

As collaboration moves onto digital platforms, reinforce your team's awareness about cybersecurity and secure coding practices to mitigate related risks.

The digital transformation in the automotive industry, characterized by the shift to Industry 4.0, has necessitated a rethink of work coordination strategies. For sustaining growth in this dynamics, a tool as comprehensive and sophisticated as KanBo becomes paramount. It allows teams to embrace an interconnected digitalized work environment, create smart factories, and leverage industry 4.0's strengths while simultaneously managing its inherent risks. A strategic approach to risk management, backed by KanBo's robust features, will be a significant driving force in the journey towards a safe, digitally-enabled Automotive Industry 4.0.

Automotive Industry 4.0: Strategies and Implementation

Automotive companies are strategically positioning themselves to meet the challenges and opportunities of Automotive 4.0. Key trends in their approach include automation, data analytics, robotics, artificial intelligence, and connected networks. These strategies are designed to enhance productivity, reduce costs, and improve customer satisfaction by delivering highly customized and quick solutions.

1. Automation and Digital Transformation 1

Companies like Volkswagen and Renault Group are investing significantly in automation technologies. Complex tasks, such as the installation of headliners in vehicles, are now being carried out by robots in some plants. The testing and implementation of automation technologies are conducted during active production periods, hence merging real-world experiences with high-tech solutions.

2. Data Analytics 2

Real-time supply management is a crucial aspect of Industry 4.0 for automotive companies. As soon as customer orders are received, suppliers are informed, raw materials are prepared, and logistics chains are established. Industry 4.0 is about complete transparency and the ability to manage data in real-time. For example, Mercedes-Benz is working with Google Cloud to create industrial solutions based on shared knowledge and expertise.

3. Robotics and Artificial Intelligence 3

Companies are leveraging technology to create a collaborative environment where humans and robots can work together in the production process. Teams comprising of people and cobots (collaborative robots) are becoming commonplace. Cobots provide heavy lifting, while humans provide expertise, therefore improving workers' environments, and enhancing productivity.

4. Connected Networks 4

The automotive industry 4.0 aims to build connected networks encompassing suppliers, employees, machines, and the products themselves. Each product is tracked from the assembly line to delivery, ensuring continuous traceability. This helps customers follow their orders in real-time and guarantees quality control.

5. Virtual Reality 5

Automotive companies are using VR for training operators, visualizing production lines, and optimizing workstation layouts. VR is transforming the learning process and providing safe and efficient methods to learn new techniques.

Final Summary

The future of the automotive industry lies within the realm of Industry 4.0, where digital transformation shapes every facet of work coordination. This integration requires the harmonization of diverse elements – from evolving communication platforms to improved data management strategies and risk mitigation tactics. The incorporation of KanBo as a project and process management tool stands out as a transformative player central to these endeavours. The objective that remains constant throughout this evolutionary journey is the need to enhance productivity, efficiency, and drive innovation while prioritizing safety and risk management.

About article

In conclusion, the coordination of work in the context of Automotive 4.0 and Industry 4.0 is a complex and constantly evolving process. This article, written by a team of contributors with extensive knowledge and experience, provides an in-depth exploration of the topic. By drawing on information from leading automotive companies such as VW, Renault, and Mercedes Benz, as well as the research conducted by Juraj Sinay and Zuzana Kotianová, this article sheds light on the emerging trends and challenges in the automotive industry. The implementation of Industry 4.0 principles, including the integration of cyber-physical systems, sensor technologies, and intelligent data management, has become crucial for automotive businesses to adapt to the changing landscape and maintain their competitiveness. With the ongoing development of technologies and the increasing automation of processes, it is essential for companies to prioritize safety measures and risk management. By embracing the principles of Industry 4.0, the automotive industry will continue to drive innovation and economic growth while ensuring the safety and efficiency of its operations.

Links and resources

- https://www.renaultgroup.com/en/innovation-2/industry-4-0-production-plants-shaped-by-the-future/

- https://group.mercedes-benz.com/innovation/case/connectivity/industry-4-0.html

- https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-40-the-production-systems-of-tomorrow-are-being-developed-in-the-glaeserne-manufaktur-in-dresden-4753

- https://www.researchgate.net/publication/331507570_Automotive_Industry_in_the_Context_of_Industry_40_Strategy

- https://www.mckinsey.com/featured-insights/mckinsey-explainers/what-is-digital-twin-technology