Table of Contents

Streamlining Processes and Enhancing Collaboration in the Automotive Industry

Efficient project management in the automotive industry relies on methodologies like Lean Manufacturing and tools like KanBo to enhance collaboration, streamline workflows, and boost efficiency, ensuring quality and innovation in a competitive market.

KanBo Work Coordination Platform

Designed for the Automotive Industry

Discover KanBo – the ultimate platform for seamless team collaboration, efficient task management, and optimized workflows. See how KanBo revolutionizes teamwork, empowering your team to accomplish more effortlessly.

Abstract

Effective project management is crucial for success in the automotive industry, where complex initiatives span multiple departments and require coordination across various stakeholders. This article explores the use of a systematic approach to enhance project management practices in the automotive industry. It examines the implementation of various methodologies such as Collaborative Project Scorecard, World Class Manufacturing, Total Quality Management, Advanced Product Quality Planning, Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standards. The article discusses how integrating these methodologies into project management processes can improve collaboration, coordination, resource management, and communication. Additionally, it highlights the benefits of leveraging a work coordination platform like KanBo for seamless integration and efficient project tracking. The findings suggest that utilizing a systematic approach can optimize project outcomes, streamline processes, enhance quality, and increase overall efficiency in the automotive industry.

Foreword

As the Director of Sales and Marketing at KanBo, I have come to recognize the eclectic nature and broad scope of project management. Much like the journey of automotive industry itself, which has travelled a long road from the age of carriage wheels and draft animals to eye-catching hybrids and self-driving vehicles, the concept of project management has evolved over the years.

The automotive industry, with its more than 100-year-old legacy, is a testament to human innovation, resilience, and relentless pursuit of progress. It is a domain that inherently espouses the core principles of project management: the ability to coordinate tasks, human resources, and technology to attain a common goal. Whether it's delivering superior comfort and safety or pushing the envelope with cutting-edge technology.

To me, project management is about giving people the means to execute an objective efficiently, rather than loading them with multiple certifications and orthodox methodologies. Within the manifold processes and structures of the automotive industry, we cannot lose sight of the simple yet powerful impetus driving every individual - the desire to contribute to a larger goal and the satisfaction of seeing it accomplished.

The aim of this article is not to add to the plethora of methodologies and best practices, but rather to underline the potential already alive within our companies' structure, our teams, and our people. This potential could be harnessed, not by inundating our personnel with certificate-driven training, but by instilling a culture of collaboration, trust, and transparency.

After all, it's not the certifications that drive innovation and success but the environment in which these skills are allowed to flourish. In this regard, a project management platform that promotes efficient coordination, transparency, and trust can truly be a gamechanger. This is the thought process that steers us in the narrative of this article.

I invite you to explore our research findings, to challenge the status quo, and to recognise the immense untapped potential within your teams. The future of project management in the automotive industry beckons new approaches and novel perspectives as we continue to evolve in an ever-changing landscape.

Arkadiusz Gos

Director of Sales and Marketing at KanBo

Introduction

Efficient project management has emerged as a pivotal fulcrum of success within the automotive industry. Recent analysis of 1108 job advertisements from this sector revealed the mention of project management skills in 256 postings. This involved outlining both job responsibilities and required skills for diverse roles, including Programme Managers, Technical Project Managers, Senior Project Managers, Software Programme Managers, and Project Managers dealing with connected products and vehicle motion integration. Implicit project management positions were also identified, encompassing roles such as Vehicle Cyber Security Managers, Manufacturing Supervisors, and Assembly Department Managers.

Given this widespread footprint, it's clear that project management is integral to the automotive sector, spanning finance transformation, engineering coordination, product development, software management, cyber security, and manufacturing supervision. But despite the existence of numerous methods and tools for project management, such as Collaborative Scorecard, World Class Manufacturing, Total Quality Management (TQM), Advanced Product Quality Management (APQP), Lean Manufacturing, Matrix Organization, Simultaneous Engineering, ISO-Technical Standards, the question arises: Can we approach this critical field in a new way?

Indeed, it's time to shift our focus from adopting new tools to harnessing existing knowledge and resources within organizations. This article proposes a shift from certification-driven training towards fostering a culture of collaboration and coordination as fundamental cornerstones of project management.

This is not an attempt to reinvent well-established paradigms but to utilize existing organizational knowledge and resources more effectively. Herein, we present a strategy of project management in Automotive based on enhanced collaboration, efficient work coordination, transparency and trust. By harnessing these values and skills that already exist within the team, we can galvanize our approach to project management, fuel innovation, and drive successful project implementation in the automotive industry.

Project Management named roles in the Automotive Industry: A Comprehensive Overview

Within the automotive industry, project management plays a critical role in overseeing and implementing various initiatives. Through our analysis of 256 job descriptions from a sample of 1108 automotive industry ads, we have identified a range of positions that are explicitly or implicitly related to project management. This summary provides an overview of the positions and areas within the automotive industry that involve project management responsibilities.

Explicit Project Management Positions:

1. Programme Manager - Finance Transformation: Responsible for leading and delivering finance transformation projects.

2. Technical Project Manager: Collaborates with engineering teams to ensure successful achievement of engineering project deliverables.

3. Senior Project Manager: Oversees multiple projects, coordinates resources, and ensures the timely completion of project objectives.

4. Programme Manager - Vehicle Motion Integration: Manages the integration of vehicle functionality across departments for powertrain, chassis, and driver assistance systems.

5. Project Leader: Provides technical leadership through all phases of project development, including design, development, certification, and production for ice and rain protection systems.

6. Software Programme Manager: Manages all software work products for vehicle projects and collaborates with various teams to ensure successful project implementation.

7. Project Manager - Connected Product: Leads the delivery of connected and digital consumer-facing products, ensuring high quality and customer satisfaction.

8. Project Buyer: Manages procurement processes for aircraft components, assemblies, and systems.

Implicit Project Management Positions:

1. Vehicle Cyber Security Manager: Responsible for establishing the product security team and developing security cases for all projects.

2. Compensation Team Lead: Provides strategic direction for designing and developing compensation programs across the organization.

3. Manufacturing Supervisor: Manages systems, procedures, and reporting related to quality management systems, ensuring daily readiness for production.

4. Technical Manager - Vehicle Motion Integration: Project manages the integration of powertrain, chassis, and driver assistance functions.

5. Assembly Department Manager: Oversees the assembly departments, tracking and reporting results to ensure high-quality production.

Areas Related to Project Management:

1. Engineering and Product Development: Positions involved in the development, integration, and testing of various vehicle components and systems.

2. Finance and Accounting: Positions responsible for financial transformation, program management, and cost analysis.

3. Supply Chain and Procurement: Positions involved in supplier management, procurement, and material planning to support project requirements.

4. Quality and Compliance: Positions responsible for ensuring compliance with regulations, managing quality analysis, and implementing improvements.

5. Corporate Strategy and Development: Positions focused on shaping the future of the organization through strategic planning and coordination of projects.

Please note that this is not an exhaustive list, as project management roles may vary across organizations within the automotive industry.

Project management is pivotal in the automotive industry, facilitating effective coordination and implementation of various initiatives across departments. Key explicit project management roles such as Programme Managers, Technical Project Managers, and Project Leaders play vital roles in leading and delivering finance and engineering projects, vehicle motion integration, software work, connected products and procurement processes.

Implicit project management roles can include positions like Vehicle Cyber Security Manager, Compensation Team Lead, and Manufacturing Supervisor which, though not directly titled as such, inherently entail management of projects focused on cybersecurity, compensation programs and manufacturing readiness respectively.

Project management is deeply ingrained in the areas of engineering and product development, finance and accounting, supply chain and procurement, quality and compliance, and corporate strategy and development. It thus aids in the efficient development and integration of vehicle components, financial transformation, supplier management, compliance with regulations, and strategic planning.

This means that project management in an automotive setting is a robust system that ensures not only the effective execution but also the strategic planning of projects across all areas of a company. Regardless of the explicitly mentioned roles, there can be a need for project management competencies in almost any position, hence the inclusion of implicitly related positions as well.

Being aware of these roles and areas can assist decision-makers in understanding where project management efforts are needed and in staffing those positions suitably. For instance, a greater emphasis may need to be placed on developing project management skills among those in roles that aren't explicitly categorised under project management but require the same skill set.

Roles with inherent project management responsibilities emphasize that anyone in your organisation, regardless of title, may drive successful projects proving that project management skills aren't exclusive to those with 'project management' in their title.

Therefore, recognising and understanding these roles and areas can help you make informed decisions about recruitment, training, and development, as well as resource allocation, to fully leverage the power of project management in your organisation.

Project Management and job responsibility in the Automotive Industry

The automotive industry relies heavily on project management to ensure the successful execution of various initiatives. From new model launches to process improvements, project management plays a crucial role in delivering high-quality products and achieving business objectives. In this analysis of job responsibilities, we identified explicit and implicit project management positions, as well as the areas these roles come from.

Explicit Project Management Positions:

1. Project Manager:

- Leads and coordinates cross-functional and cross-departmental projects.

- Develops project plans, sets timelines, and manages budgets.

- Ensures deliverables are met and project goals are achieved.

- Responsible for effective communication and stakeholder engagement.

2. Program Manager:

- Manages multiple projects and initiatives within a program.

- Provides overall strategic direction and oversight for projects.

- Collaborates with cross-functional teams to align project objectives.

- Ensures successful delivery of program outcomes.

3. PMO (Project Management Office) Lead (Project Management Office):

- Sets up and maintains project management processes and standards.

- Supports project managers by supplying guidance and resources.

- Monitors project performance and provides regular updates to stakeholders.

- Conducts project reviews and finds areas for improvement.

Implicit Project Management Positions:

1. Supply Chain Manager:

- Manages and coordinates the supply chain for new model launches.

- Ensures timely delivery of components and materials to support production.

- Collaborates with suppliers and internal teams to resolve issues and optimize processes.

- Tracks and reports on key performance indicators related to supply chain management.

2. Quality Control Manager:

- Integrates quality management principles into project planning and execution.

- Defines quality standards and monitors adherence throughout the project lifecycle.

- Implements corrective actions to address quality issues and prevent recurrence.

- Conducts audits and assessments to evaluate project performance against quality goals.

Areas from Which Project Management Roles Come:

1. Engineering:

- Project managers in this area oversee the development and implementation of new technologies and vehicle features.

- They collaborate with design and development teams to ensure projects meet technical requirements and are delivered on time.

2. Procurement:

- Supply chain managers play a critical role in project management by ensuring the timely and cost-effective delivery of parts and components.

- They collaborate with suppliers and internal stakeholders to optimize supply chain processes and mitigate risks.

3. Manufacturing:

- Project managers in manufacturing are responsible for coordinating and implementing process improvements and production line changes.

- They work closely with cross-functional teams to minimize disruptions and ensure efficient operations during project execution.

4. Quality Assurance:

- Quality control managers contribute to project management by ensuring that quality standards are met throughout the project lifecycle.

- They collaborate with project teams to identify and address quality issues, ensuring the final product meets customer expectations.

Cross Functional and Cross Departmental Projects:

Many of the project management roles in the automotive industry involve leading cross-functional and cross-departmental projects. These projects require collaboration and coordination between engineering, procurement, manufacturing, quality assurance, and other departments to ensure successful outcomes. Project managers in these roles need to facilitate effective communication, manage interdependencies, and align project goals across multiple functions and departments.

Project management roles play a pivotal role in the automotive industry, ensuring the successful realization of various initiatives. These roles are comprehensively outlined in both explicit and implicit job functions.

Explicit roles like project managers, program managers and PMO Leads take charge of organizing and executing cross-functional projects, managing multiple projects within a program, setting strategic directions, and overseeing the overall project management processes respectively.

Implicit roles like supply chain managers and quality control managers ensure a smooth supply of components for production and integrate quality management principles into project execution.

The origin of these roles can be traced back to different areas such as engineering, procurement, manufacturing, and quality assurance. Project managers in engineering help in the development of new technologies, supply chain managers in procurement ensure effective delivery of components, those in manufacturing coordinate process improvements, while quality control managers in quality assurance ensure that quality standards are adhered to.

Most importantly, project management in the automotive industry often involves managing cross-functional and cross-departmental projects. This requires collaboration and coordination across various departments like engineering, procurement, manufacturing, and quality assurance. For successful outcomes, project managers need to facilitate effective interdepartmental communication, manage dependencies and align project objectives across different functions.

Effective project management is central to the successful operation of a large automotive company. It ensures timely launches, process improvements, and high-quality standards that meet customer expectations and business goals. It is therefore crucial for decision-makers in the automotive industry to understand the importance of these roles and ensure they are properly filled and supported.

Analyzing Project Management Skills in the Automotive Industry

In the automotive industry, project management plays a crucial role in ensuring successful product development, manufacturing, and delivery. By analyzing job postings from the industry, we can identify the skills and positions that are closely related to project management. This analysis will provide insights into the explicit and implicit skills required for effective project management in the automotive sector.

Explicit Skills Related to Project Management:

1. Planning and Scheduling: Positions such as "Project Manager" and "Program Manager" explicitly mention the responsibility of creating and managing project plans, timelines, and schedules.

2. Budget Management: Many positions require skills in budget development, use tracking, and analysis to ensure projects are delivered within the allocated financial resources.

3. Stakeholder and Change Management: Job responsibilities often include collaborating with cross-functional teams, departments, and stakeholders to ensure smooth project execution and manage any changes that may arise.

Implicit Skills Related to Project Management:

1. Problem-Solving: While not explicitly mentioned in job descriptions, project managers in the automotive industry are expected to have strong problem-solving skills to identify issues, develop solutions, and implement corrective actions.

2. Leadership and Communication: Effective project management requires excellent leadership skills to motivate and guide teams. Effective communication skills are necessary to clearly convey project goals, objectives, and progress to stakeholders.

3. Risk Assessment and Mitigation: Project managers are responsible for identifying potential risks and developing strategies to mitigate them. This skill is important in the automotive industry to address uncertainties related to product development and manufacturing.

Areas from which Project Management Positions Come:

1. Operations: Positions related to project management often come from areas such as manufacturing, supply chain, and logistics, where project coordination and integration are essential.

2. Research and Development: Project management positions can also be found in R&D (Research & Development) departments to oversee new product development and innovation projects.

Cross-Functional and Cross-Departmental Projects:

Project managers in the automotive industry are often involved in cross-functional and cross-departmental projects. These projects require collaboration and coordination between various teams, including engineering, manufacturing, quality, procurement, and finance, to ensure the successful delivery of products.

Skills Not Obvious for Project Management but Important:

1. Technical Knowledge: While project management skills are vital, understanding technical aspects, such as automotive engineering and manufacturing processes, can enhance a project manager's effectiveness in decision-making and problem-solving.

2. Change Management: Given the dynamic nature of the automotive industry, project managers must possess skills in change management to adapt to evolving market conditions, regulations, and customer demands.

3. Quality Management: Understanding and implementing quality management principles and processes are crucial in ensuring that projects meet the required quality standards.

Project management in the automotive industry requires a combination of explicit skills such as planning, scheduling, and budget management, along with implicit skills like problem-solving, leadership, and risk assessment. Project managers often come from operations and R&D departments, and they are involved in cross-functional and cross-departmental projects. Technical knowledge, change management, and quality management are also essential skills for effective project management in the automotive sector.

Project management in the automotive industry is paramount, encompassing both explicit and implicit skills to ensure productive outcomes.

Explicit skills such as planning and scheduling, budget management, and stakeholder/change management are fundamental. As project managers, you must be adept at developing project plans, managing timelines, and staying within a budget. You will also work with various teams and stakeholders and manage any changes that occur during the project lifecycle.

Implicit skills also hold significant value. Problem-solving, for instance, is critical in identifying, addressing, and resolving project challenges. Leadership and communication are necessary in guiding teams and conveying project objectives effectively. Identifying potential risks and developing right mitigation strategies is also implicit in project management.

Project management roles typically emerge from operations (like manufacturing, supply chain) and Research and Development (R&D), requiring you to have a good understanding of these areas. Handling cross-functional and cross-departmental projects is common, involving coordination with teams like engineering, manufacturing, procurement, and finance.

Apart from these, some core skills do not typically stand out in project management but are incredibly important. Technical knowledge is one such skill; understanding automotive engineering and manufacturing processes is crucial to informed decision-making and problem-solving. Change management is another important skill due to the evolving nature of the automotive industry. Moreover, knowledge of quality management principles and processes is essential to ensure that projects meet specific quality standards.

Excellence in project management requires the right blend of explicit and implicit skills, technical knowledge, and adaptability, making it an integral part of the automotive industry’s success.

Project management is essential in the automotive industry for successful product development and delivery. Explicit project management positions include Project Managers, Program Managers, and PMO Leads, who are responsible for planning, budget management, stakeholder management, and change management. Implicit skills include problem-solving, leadership, communication, and risk assessment. Project management positions often originate from operations and R&D departments, and cross-functional and cross-departmental projects are common. Additional skills like technical knowledge, change management, and quality management are also important. Overall, project management is crucial to achieving business objectives in the automotive industry.

Analysis of Project Management Practices in the Automotive Industry

This section provides a comprehensive review and summary of a scientific publication. The focus is on the evaluation of Project Management (PM) implementations in the Original Equipment Manufacturing (OEM) sector of the automotive industry. The PM practices within various industries like aerospace and construction have proven to be effective in project success. These practices have led to better resource management and has resulted in increased concentration on strategic objectives. Despite such success, the implementation within the automotive industry, specifically within the OEM suppliers who are mostly small to medium-sized companies, is surprisingly low. As a result, the paper aims to explore the status of this PM implementation within the automotive

OEM industry, particularly in Italy. The methodology involved a survey sent to participants in this industry, from which gathered data was analyzed.

Redefining Project Management in the Automotive Industry with KanBo

In an analysis of advertisements published by companies in the automotive industry, it was revealed that Project Management was a significant theme, appearing in approximately 23% of the 1108 advertisements reviewed. The importance of this area cannot be emphasized enough - with Project Management entailing a broad range of tasks needing specific skill sets, it is centred on collaboration and coordination. As saw, a variety of methodologies and tools are employed within the sector to manage projects effectively. These include the Collaborative Scorecard, World Class Manufacturing, Total Quality Management (TQM), Advanced Product Quality Management (APQP), Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standard, among others.

However, a significant enhancement in project management can be achieved when companies in the automotive industry integrate the KanBo work coordination platform into their operations. The platform's versatility allows for seamless integration with the above-mentioned methodologies, translating to improved efficiency.

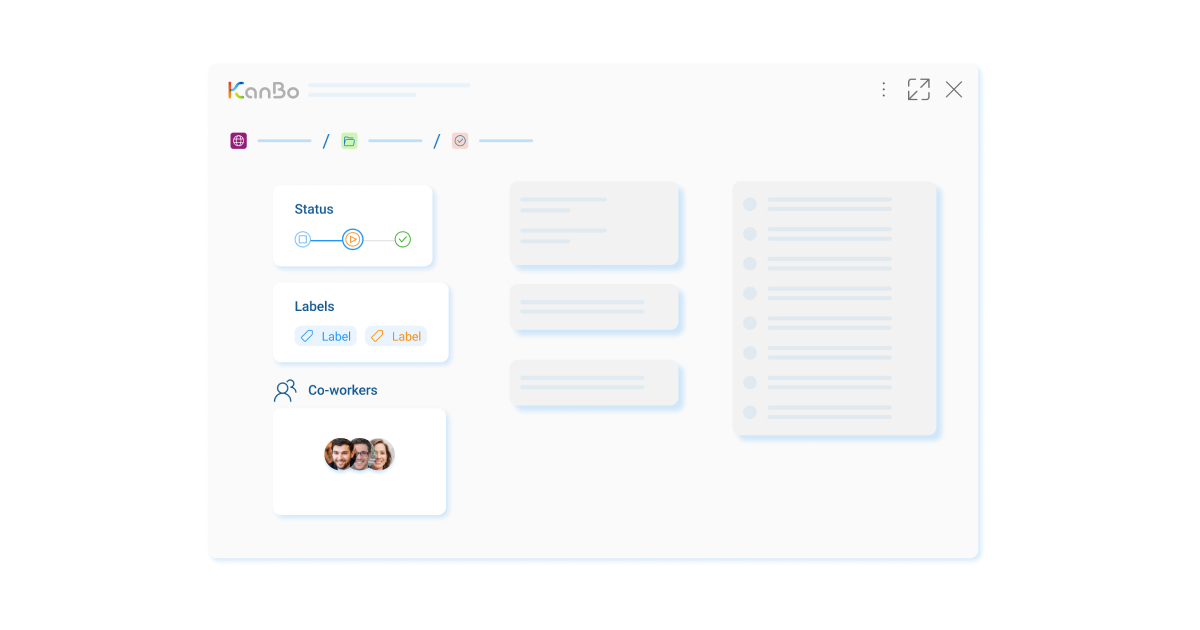

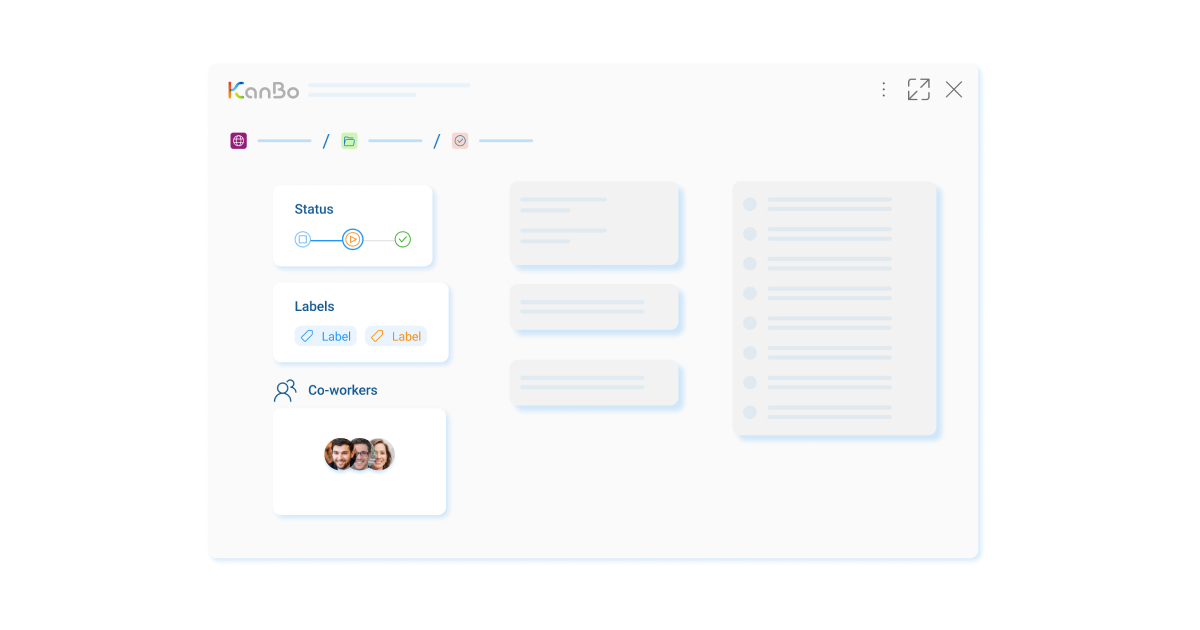

KanBo offers a collection of cards, or tasks, arranged in a highly customizable space, representing the workflow. With its in-built activity stream, you get a chronological list of all activities and updates related to a specific project. Its three-view feature allows you to switch between the Kanban, Gantt, and Timeline view basing on your needs at a particular moment. This, alongside KanBo's search and filter functions, allows for easy tracking and management of progress.

KanBo's feature of collaborative document editing, note-making, and bookmarking means all necessary project information is readily available, fostering efficient communication within teams. With the adoption of KanBo, project management within the automotive industry undergoes a transformation, becoming more streamlined, organized, and productive.

Harnessing Collaboration through the Collaborative Project Scorecard and KanBo in the Automotive Industry

The Collaborative Project Scorecard (CPS) is a project-focused modification of the Balanced Scorecard, devised to align project goals with business strategies whilst facilitating system integration management through a common vision and processes. The structure of CPS comprises three elements - levels, cause and effect relationships, and indicators, building upon the fundamentals of continuous communication, compliance, improvement, and cooperation. This scorecard has proven particularly effective in the automotive industry, where the dynamism of identifying significant Key Performance Indicators (KPIs) and project objectives correspond with cross-organizational strategies.

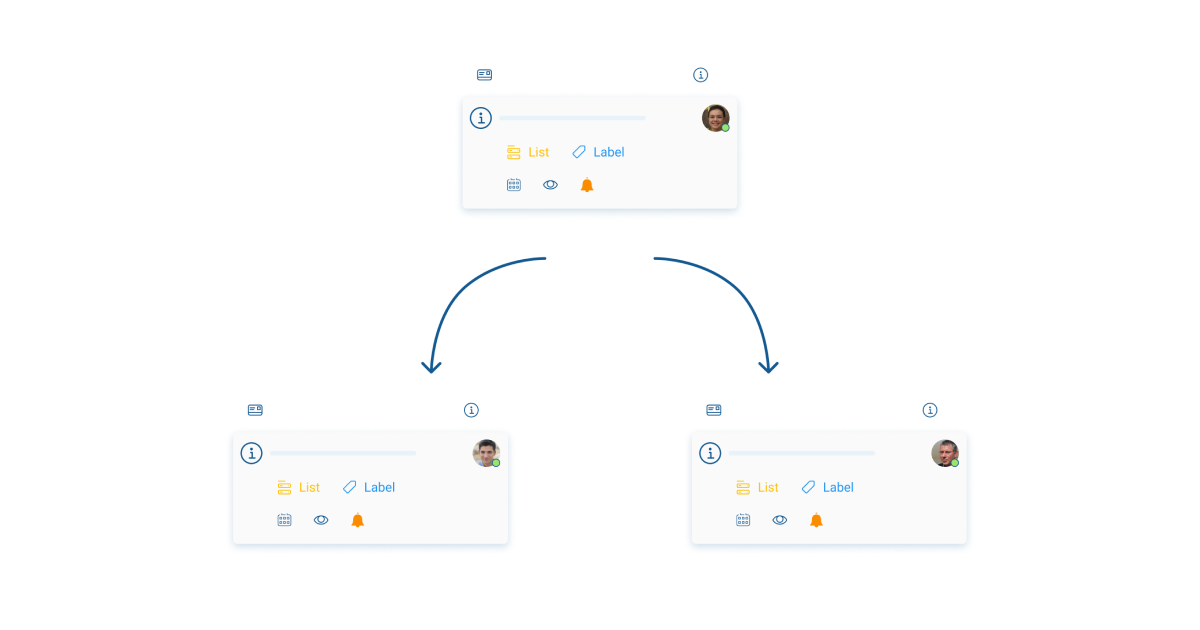

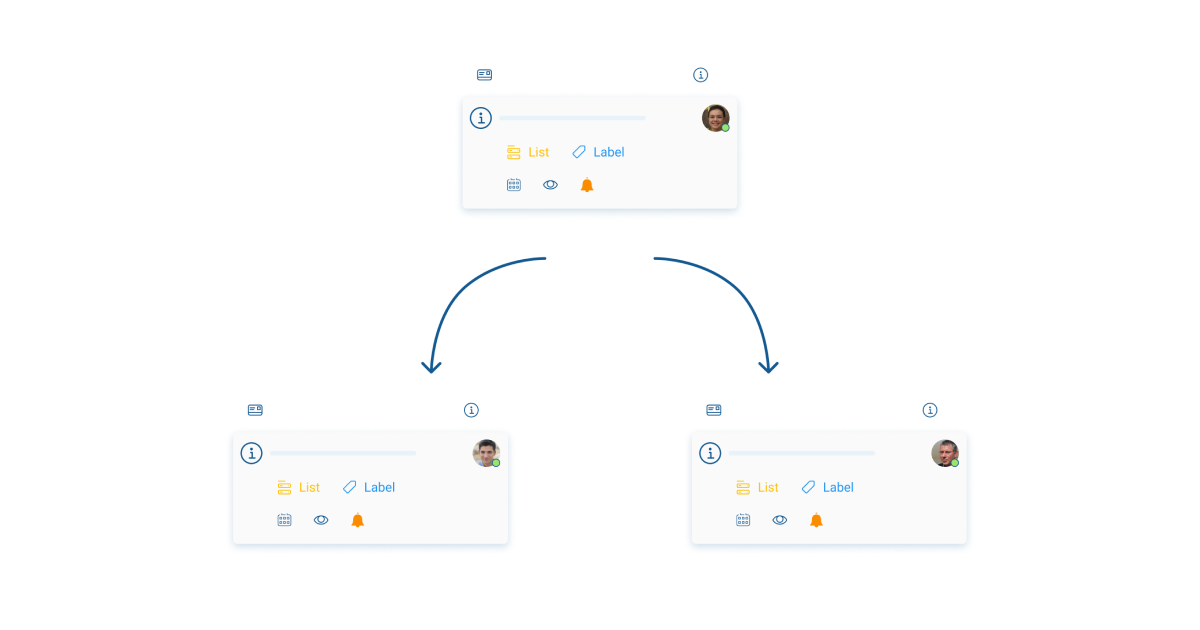

Incorporating the KanBo work coordination platform into CPS implementation offers several promising advantages in automotive project management. With features such as the activity stream, card details, and card activity stream, KanBo allows for comprehensive task tracking, efficient information logging, and easy access to project updates, respectively. A more personalized management approach can be created for each team member using the personal space view, granting them an individualized overview of their tasks within the project.

With the card user feature, delegation and assignment of tasks can be effectively managed as project leaders can see who is responsible for each task. Paired with the card status feature, project managers can also track the progress of each task. KanBo's notification feature further supports communication in the project, alerting team members of significant updates or changes in project status.

By merging the organization and clarity of the Collaborative Project Scorecard with the dynamic and interactive features of KanBo, automotive companies can significantly enhance their approach to project management.

Implementing World Class Manufacturing in the Automotive Industry with KanBo

World Class Manufacturing (WCM) is a holistic and systematic approach aimed at continuous improvement of processes and systems to reach optimal production standards. It integrates key methodologies such as Lean Manufacturing, Six Sigma, and Total Productive Maintenance, striving towards better, faster, and cheaper production while promoting agility in operations. In the automotive industry, WCM becomes an instrumental tool facilitating incessant communication and collaboration with both customers and suppliers.

Incorporating KanBo, a work coordination platform, into the WCM approach, can significantly boost project management standards in the automotive sector. With KanBo cards, tasks or projects can be managed effectively since they contain essential information such as notes, files, comments, dates, and checklists. These cards can then be grouped according to different criteria such as due dates or status, aiding in the organization of tasks.

The Kanban View feature allows visualization of a space divided into columns, reflecting the various stages of work in the project, characteristic of the lean approach in WCM. Additionally, the Mind Map view offers a graphical representation of relations between different tasks for better comprehension of project dependencies.

KanBo’s space activity stream offers users real-time logs of all activities, updates related to tasks providing transparency, and enhancing project management. Furthermore, enabling the use of card statuses can complement the WCM implementation by facilitating identification of the current stage or condition of tasks. The flexibility and vast functionality of KanBo make it an ideal project management platform in the path to World Class Manufacturing.

Total Quality Management (TQM) and KanBo: Enhancing Project Management in the Automotive Industry

Total Quality Management (TQM) has been widely adopted in the automotive industry and has proven beneficial for quality and corporate performance. This approach is rooted in the organizational management strategy aimed at improving customers’ satisfaction by examining the intrinsic basic processes of all business operations. It falls under the tenets of the World Class Manufacturing (WCM) approach which encourages interaction with both customers and suppliers. This is where the use of KanBo, an advanced work coordination platform, becomes crucial.

In the context of automotive industry project management, KanBo facilitates effective communication and collaboration among everyone involved in the process. It integrates seamlessly with the TQM approach by enhancing the quality management procedures, particularly in product development, realization, and launch phases. Through its advanced features such as activity stream, card details, card relations, Kanban view, and space user among others, KanBo allows for the efficient planning and management of tasks.

For instance, the card details feature can encapsulate vital information about a task, including time frame, responsible persons, and related tasks. Additionally, the card relations feature can show the interconnectedness between tasks. It helps to set up a clear workflow and shows the dependencies between tasks, where each card represents a task or a project that needs to be tracked. Kanban view is especially helpful in visualizing the progression of tasks, keeping the record of the completion status of each task and facilitating the timely completion of projects.

Thus, integrating Total Quality Management (TQM) practices with the KanBo platform can significantly streamline project management in the automotive industry, leading to better coordination, improved quality, and increased overall efficiency.

Advanced Product Quality Planning (APQP) Enhanced by KanBo in Automotive Industry Project Management

Advanced Product Quality Planning (APQP) is a standardized process in the automotive industry that facilitates communication between all stakeholders involved in the project, starting from team organization to involvement of customers and suppliers. It primarily focuses on quality management procedures and is extensively benefited in all phases of product development, realization, and product launch.

APQP with KanBo becomes a dynamic workforce, as KanBo optimizes project management with its various features. Begin with a well-organized "space", where every task and requirement can be arranged into separate "cards". Each "card" can represent the various stages of APQP, beginning from market research to production, with the flexibility to add detailed instructions, specific actions, or additional task-related documents.

Moreover, "card user" features allow each member of the team, including stakeholders, suppliers, and customers, to be assigned a specific responsibility, thereby building a cross-functional team aimed at achieving the common goal. "Card date" functions can be used to schedule and highlight important milestones, ensuring everyone is up to date with the project deadlines. The "activity stream" on each card keeps everyone informed about the project's real-time status and progress.

KanBo’s "bookmark" feature can be used for tagging and referencing crucial discussions for future decisions. Additionally, the "card relation" feature would deliver clear hierarchical and dependency between tasks showing cause-effective relationships.

APQP implementation becomes more transparent and efficient when mapped with KanBo, providing a clear quality planning business process in automotive project management. The simultaneous engineering or concurrent engineering that APQP encourages can be effortlessly coordinated within the KanBo platform making it a wise choice for Automotive Industry Project Management.

Utilizing KanBo for Lean Manufacturing in Automotive Project Management

Lean Manufacturing is a systematic method aimed at reducing waste within the manufacturing process, enhancing productivity, and increasing overall customer value. This principle plays a vital role in automotive project management, with the automotive industry constantly striving for optimization and cost-efficiency. Implementing Lean Manufacturing principles not only ensures continuous improvement but also plays a significant role in enhancing product quality and customer satisfaction.

In practice, Lean Manufacturing principles often require effective coordination, real-time communication, and constant progress tracking. This is where a work coordination platform like KanBo comes into play. Automobile companies can leverage and seamlessly integrate KanBo's capabilities into their Lean Manufacturing practices.

Among KanBo's multifaceted features, its activity stream offers real-time logs to monitor progress, while its card feature facilitates task representation and management. With card statuses showing the current stage of a task, KanBo brings to light Lean Manufacturing value of visual management and real-time status tracking. Also, KanBo's automated reminders can help ensure tasks are completed on time and product specifications are met, which aligns with Lean Manufacturing’s emphasis on timeliness and product quality.

The platform's 'space view' feature, which presents visual representations of project contents, complements Lean Manufacturing's concept of visual control, enabling project managers to arrange tasks efficiently. Furthermore, the application of KanBo’s document source feature aids in seamless integration and effective organization of project-relevant documents.

To sum up, KanBo's features, and Lean Manufacturing principles can work in symbiosis to enhance project management practices in automotive companies, leading to streamlined processes, reduced waste, and improved overall productivity.

Matrix Organization in Automotive Industry - Efficient Coordination using KanBo

Matrix Organization, a management practice prevalent in the automotive sector, involves the arrangement of team members with similar skills for project work where they report to multiple superiors. This structure bolsters project management by empowering Project Managers with control over resources and the project's course while Functional Managers offer necessary auxiliary advice.

In enhancing project management, the adoption of KanBo as a tool for work coordination seamlessly aligns with the Matrix organizational structure in the automotive industry. By employing essential KanBo features, the streamlined project management process can be realized.

With KanBo's 'Activity Stream', each project's progression is documented in real-time, providing an exact and chronological log of updates. 'Space', another notable feature, allows the organization of work into categorized projects, making management more straightforward. KanBo's 'Card' feature serves as a task tracking tool, with all essential information like notes, files, deadlines, and checklists attached, ensuring no details are missed out.

Additionally, the 'Personal Space View' customization provides individual users with a personalized work management approach. Coordination and communication are further enhanced using 'Chat', providing a real-time messaging system within projects, and 'Comments' that allow team discussion and information sharing.

For an efficient Matrix Organization workflow in the automotive industry, adopting KanBo as a key project management tool proves vital. The platform's user-friendly, intuitive interface and efficient features optimize work coordination, ensuring project success.

Enhancing Simultaneous Engineering with KanBo for Automotive Project Management

Simultaneous Engineering (SE) is a critical practice within the automotive industry for project development. It intricately maps out the process to be followed in project development. Adopting SE allows companies to develop various solutions in parallel, ensuring the streamlined execution of the project without resorting to working with a single scenario at a time. In this modern, multilayered approach, the development of products is conducted alongside the functions of other departments, such as logistics networks and production systems.

Implementing the SE approach with KanBo as a platform for project management can significantly boost efficiency. KanBo features like collaborative platform and Matrix Organization work hand in hand with SE principles. The collaborative platform ensures that project documents and relevant information are well-structured and easily accessible to all stakeholders. On the other hand, the Matrix Organization allows pooling of employees with similar skill sets, who report to multiple managers, ensuring every aspect of the project is well accounted for by experts in the field.

KanBo's 'Card' feature can serve as a representation of the myriad of tasks that need to be executed in the SE. These tasks can be easily managed, tracked, and updated in real-time, ensuring project milestones are achieved promptly. The 'Card Relation' feature allows for breaking down the large tasks into manageable units, thereby improving organization and task sequencing.

Employing KanBo as the platform for project management will not only facilitate the implementation of Simultaneous Engineering but will also significantly enhance the collaborative work environment, leading to the successful completion of automotive projects.

Adopting KanBo for Effective Project Management in Accordance with ISO-Technical Standards in the Automotive Industry

ISO-Technical Standards are international guidelines that provide a detailed understanding of best practices and industry standards relevant to any sector, including the automotive industry. They show specific requirements for quality planning, approval processes, failure modes and effect analysis, statistical process control, and measurement systems. The guidelines provided can help in process design/development and are highly effective in ensuring an organization's products or services meet customer requirements, while simultaneously reducing variation and waste in the supply chain.

Applying these standards allows automotive companies to employ the work coordination platform KanBo effectively. KanBo offers an array of features designed to enhance project management such as activity stream, card templates, space views, GraphQL APIs (Application Programming Interfaces) among others. For instance, the card system in KanBo can be used to align with the ISO/TS 1649 requirements by providing a standardized way of managing tasks and tracking their progress. Also, a balanced scorecard or a performance metric used in strategic management can be implemented through the KanBo software to align business activities to the vision and strategy of the organization, improve internal and external communications, and check organization performance against strategic goals. Utilizing these features in conformance with the ISO standards notably bolsters the project management approach in the automotive industry, leading to much-improved quality and efficiency.

The adoption of project management (PM) strategies is surprisingly low in the Original Equipment Manufacturing (OEM) sector of the automotive industry. To address this, this comprehensive review explores project management practices used within the industry, specifically amongst smaller OEM suppliers in Italy. Several methodologies and tools were highlighted, including the Collaborative Scorecard, World Class Manufacturing, and Total Quality Management.

KanBo, a work coordination platform, can significantly enhance project management practices if integrated into these strategies used in the automotive industry. Its array of features allows for efficient communication, better organization, task tracking, and overall project management improvement. The review further explores how KanBo can enhance methodologies like Advanced Product Quality Planning (APQP), Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standards within the sector, leading to better project outcomes and improved efficiency.

Best Practices for Effective Project Management in the Automotive Industry Using KanBo

Streamlining project management in the automotive industry involves several universal issues that can be solved by leveraging KanBo. These include practical application, information sharing, production control, process management, and handling complex projects.

Practical application

Practical application refers to how a theoretical plan is applied to the real project. Through features like card and space templates, KanBo aids in turning ideas into practical step-by-step tasks. A more efficient practical implementation can significantly increase the project's efficiency.

The sharing of information

The sharing of information, which entails effective communication, collaboration, and information dissemination among stakeholders, is a key part of project management. With KanBo, project members can use its built-in comment and mention feature for direct communication or use activity streams and status on cards to update others about progress.

Control of production

Control of production and services primarily revolves around managing the flow and quality of output. Lean manufacturing principles, coupled with its APQP (Advanced Product Quality Planning) tool, helps in continual monitoring, leading to better control over production and services.

Processes

Processes involve a series of sequential tasks to be done within a project. KanBo leverages features like card relations, which allow users to establish connections between different tasks, making it easier to manage and track complex processes.

Complex projects

Handling complex projects, especially in the automotive industry, can be quite challenging. Here, KanBo offers unique solutions like Gantt Chart, Kanban, and Mind Map view, which helps visually organize project tasks, keeping track of a project's timelines, and ensuring that all components of the project are closely interlinked and organized.

Clearly defined KanBo features equip automotive companies with the necessary tools to effectively manage projects, streamline processes, and boost productivity.

Final Word

The implementation of effective project management practices in the automotive industry is crucial for successful product development, manufacturing, and delivery. By integrating methodologies like KanBo, Collaborative Project Scorecard, World Class Manufacturing, Total Quality Management, Advanced Product Quality Planning, Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standards, automotive companies can enhance collaboration, coordination, and resource management. KanBo, as a work coordination platform, provides a seamless integration of these methodologies, offering features that facilitate task tracking, communication, document management, and progress monitoring. By adopting a systematic approach and leveraging the power of KanBo, the automotive industry can optimize project outcomes, streamline processes, enhance quality, and drive overall efficiency.

Links and resources

- https://www.sciencedirect.com/science/article/pii/S1877050921001915

- https://kanboapp.com/en/industries/automotive/

- https://en.wikipedia.org/wiki/Total_quality_management

- https://en.wikipedia.org/wiki/Advanced_product_quality_planning

- https://en.wikipedia.org/wiki/Lean_manufacturing

- https://en.wikipedia.org/wiki/Matrix_management

- https://www.linkedin.com/pulse/instant-team-collaboration-possible-discover-how-kanbo-arkadiusz-gos

- https://help.kanboapp.com/en/hc/

- https://kanboapp.com/en/blog/project-management-made-easy-with-kanbo/

Table of Contents

Streamlining Processes and Enhancing Collaboration in the Automotive Industry

Efficient project management in the automotive industry relies on methodologies like Lean Manufacturing and tools like KanBo to enhance collaboration, streamline workflows, and boost efficiency, ensuring quality and innovation in a competitive market.

Abstract

Effective project management is crucial for success in the automotive industry, where complex initiatives span multiple departments and require coordination across various stakeholders. This article explores the use of a systematic approach to enhance project management practices in the automotive industry. It examines the implementation of various methodologies such as Collaborative Project Scorecard, World Class Manufacturing, Total Quality Management, Advanced Product Quality Planning, Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standards. The article discusses how integrating these methodologies into project management processes can improve collaboration, coordination, resource management, and communication. Additionally, it highlights the benefits of leveraging a work coordination platform like KanBo for seamless integration and efficient project tracking. The findings suggest that utilizing a systematic approach can optimize project outcomes, streamline processes, enhance quality, and increase overall efficiency in the automotive industry.

KanBo Work Coordination Platform

Designed for the Automotive Industry

Discover KanBo – the ultimate platform for seamless team collaboration, efficient task management, and optimized workflows. See how KanBo revolutionizes teamwork, empowering your team to accomplish more effortlessly.

Foreword

As the Director of Sales and Marketing at KanBo, I have come to recognize the eclectic nature and broad scope of project management. Much like the journey of automotive industry itself, which has travelled a long road from the age of carriage wheels and draft animals to eye-catching hybrids and self-driving vehicles, the concept of project management has evolved over the years.

The automotive industry, with its more than 100-year-old legacy, is a testament to human innovation, resilience, and relentless pursuit of progress. It is a domain that inherently espouses the core principles of project management: the ability to coordinate tasks, human resources, and technology to attain a common goal. Whether it's delivering superior comfort and safety or pushing the envelope with cutting-edge technology.

To me, project management is about giving people the means to execute an objective efficiently, rather than loading them with multiple certifications and orthodox methodologies. Within the manifold processes and structures of the automotive industry, we cannot lose sight of the simple yet powerful impetus driving every individual - the desire to contribute to a larger goal and the satisfaction of seeing it accomplished.

The aim of this article is not to add to the plethora of methodologies and best practices, but rather to underline the potential already alive within our companies' structure, our teams, and our people. This potential could be harnessed, not by inundating our personnel with certificate-driven training, but by instilling a culture of collaboration, trust, and transparency.

After all, it's not the certifications that drive innovation and success but the environment in which these skills are allowed to flourish. In this regard, a project management platform that promotes efficient coordination, transparency, and trust can truly be a gamechanger. This is the thought process that steers us in the narrative of this article.

I invite you to explore our research findings, to challenge the status quo, and to recognise the immense untapped potential within your teams. The future of project management in the automotive industry beckons new approaches and novel perspectives as we continue to evolve in an ever-changing landscape.

Arkadiusz Gos

Director of Sales and Marketing at KanBo

Introduction

Efficient project management has emerged as a pivotal fulcrum of success within the automotive industry. Recent analysis of 1108 job advertisements from this sector revealed the mention of project management skills in 256 postings. This involved outlining both job responsibilities and required skills for diverse roles, including Programme Managers, Technical Project Managers, Senior Project Managers, Software Programme Managers, and Project Managers dealing with connected products and vehicle motion integration. Implicit project management positions were also identified, encompassing roles such as Vehicle Cyber Security Managers, Manufacturing Supervisors, and Assembly Department Managers.

Given this widespread footprint, it's clear that project management is integral to the automotive sector, spanning finance transformation, engineering coordination, product development, software management, cyber security, and manufacturing supervision. But despite the existence of numerous methods and tools for project management, such as Collaborative Scorecard, World Class Manufacturing, Total Quality Management (TQM), Advanced Product Quality Management (APQP), Lean Manufacturing, Matrix Organization, Simultaneous Engineering, ISO-Technical Standards, the question arises: Can we approach this critical field in a new way?

Indeed, it's time to shift our focus from adopting new tools to harnessing existing knowledge and resources within organizations. This article proposes a shift from certification-driven training towards fostering a culture of collaboration and coordination as fundamental cornerstones of project management.

This is not an attempt to reinvent well-established paradigms but to utilize existing organizational knowledge and resources more effectively. Herein, we present a strategy of project management in Automotive based on enhanced collaboration, efficient work coordination, transparency and trust. By harnessing these values and skills that already exist within the team, we can galvanize our approach to project management, fuel innovation, and drive successful project implementation in the automotive industry.

Project Management named roles in the Automotive Industry: A Comprehensive Overview

Within the automotive industry, project management plays a critical role in overseeing and implementing various initiatives. Through our analysis of 256 job descriptions from a sample of 1108 automotive industry ads, we have identified a range of positions that are explicitly or implicitly related to project management. This summary provides an overview of the positions and areas within the automotive industry that involve project management responsibilities.

Explicit Project Management Positions:

1. Programme Manager - Finance Transformation: Responsible for leading and delivering finance transformation projects.

2. Technical Project Manager: Collaborates with engineering teams to ensure successful achievement of engineering project deliverables.

3. Senior Project Manager: Oversees multiple projects, coordinates resources, and ensures the timely completion of project objectives.

4. Programme Manager - Vehicle Motion Integration: Manages the integration of vehicle functionality across departments for powertrain, chassis, and driver assistance systems.

5. Project Leader: Provides technical leadership through all phases of project development, including design, development, certification, and production for ice and rain protection systems.

6. Software Programme Manager: Manages all software work products for vehicle projects and collaborates with various teams to ensure successful project implementation.

7. Project Manager - Connected Product: Leads the delivery of connected and digital consumer-facing products, ensuring high quality and customer satisfaction.

8. Project Buyer: Manages procurement processes for aircraft components, assemblies, and systems.

Implicit Project Management Positions:

1. Vehicle Cyber Security Manager: Responsible for establishing the product security team and developing security cases for all projects.

2. Compensation Team Lead: Provides strategic direction for designing and developing compensation programs across the organization.

3. Manufacturing Supervisor: Manages systems, procedures, and reporting related to quality management systems, ensuring daily readiness for production.

4. Technical Manager - Vehicle Motion Integration: Project manages the integration of powertrain, chassis, and driver assistance functions.

5. Assembly Department Manager: Oversees the assembly departments, tracking and reporting results to ensure high-quality production.

Areas Related to Project Management:

1. Engineering and Product Development: Positions involved in the development, integration, and testing of various vehicle components and systems.

2. Finance and Accounting: Positions responsible for financial transformation, program management, and cost analysis.

3. Supply Chain and Procurement: Positions involved in supplier management, procurement, and material planning to support project requirements.

4. Quality and Compliance: Positions responsible for ensuring compliance with regulations, managing quality analysis, and implementing improvements.

5. Corporate Strategy and Development: Positions focused on shaping the future of the organization through strategic planning and coordination of projects.

Please note that this is not an exhaustive list, as project management roles may vary across organizations within the automotive industry.

Project management is pivotal in the automotive industry, facilitating effective coordination and implementation of various initiatives across departments. Key explicit project management roles such as Programme Managers, Technical Project Managers, and Project Leaders play vital roles in leading and delivering finance and engineering projects, vehicle motion integration, software work, connected products and procurement processes.

Implicit project management roles can include positions like Vehicle Cyber Security Manager, Compensation Team Lead, and Manufacturing Supervisor which, though not directly titled as such, inherently entail management of projects focused on cybersecurity, compensation programs and manufacturing readiness respectively.

Project management is deeply ingrained in the areas of engineering and product development, finance and accounting, supply chain and procurement, quality and compliance, and corporate strategy and development. It thus aids in the efficient development and integration of vehicle components, financial transformation, supplier management, compliance with regulations, and strategic planning.

This means that project management in an automotive setting is a robust system that ensures not only the effective execution but also the strategic planning of projects across all areas of a company. Regardless of the explicitly mentioned roles, there can be a need for project management competencies in almost any position, hence the inclusion of implicitly related positions as well.

Being aware of these roles and areas can assist decision-makers in understanding where project management efforts are needed and in staffing those positions suitably. For instance, a greater emphasis may need to be placed on developing project management skills among those in roles that aren't explicitly categorised under project management but require the same skill set.

Roles with inherent project management responsibilities emphasize that anyone in your organisation, regardless of title, may drive successful projects proving that project management skills aren't exclusive to those with 'project management' in their title.

Therefore, recognising and understanding these roles and areas can help you make informed decisions about recruitment, training, and development, as well as resource allocation, to fully leverage the power of project management in your organisation.

Project Management and job responsibility in the Automotive Industry

The automotive industry relies heavily on project management to ensure the successful execution of various initiatives. From new model launches to process improvements, project management plays a crucial role in delivering high-quality products and achieving business objectives. In this analysis of job responsibilities, we identified explicit and implicit project management positions, as well as the areas these roles come from.

Explicit Project Management Positions:

1. Project Manager:

- Leads and coordinates cross-functional and cross-departmental projects.

- Develops project plans, sets timelines, and manages budgets.

- Ensures deliverables are met and project goals are achieved.

- Responsible for effective communication and stakeholder engagement.

2. Program Manager:

- Manages multiple projects and initiatives within a program.

- Provides overall strategic direction and oversight for projects.

- Collaborates with cross-functional teams to align project objectives.

- Ensures successful delivery of program outcomes.

3. PMO (Project Management Office) Lead (Project Management Office):

- Sets up and maintains project management processes and standards.

- Supports project managers by supplying guidance and resources.

- Monitors project performance and provides regular updates to stakeholders.

- Conducts project reviews and finds areas for improvement.

Implicit Project Management Positions:

1. Supply Chain Manager:

- Manages and coordinates the supply chain for new model launches.

- Ensures timely delivery of components and materials to support production.

- Collaborates with suppliers and internal teams to resolve issues and optimize processes.

- Tracks and reports on key performance indicators related to supply chain management.

2. Quality Control Manager:

- Integrates quality management principles into project planning and execution.

- Defines quality standards and monitors adherence throughout the project lifecycle.

- Implements corrective actions to address quality issues and prevent recurrence.

- Conducts audits and assessments to evaluate project performance against quality goals.

Areas from Which Project Management Roles Come:

1. Engineering:

- Project managers in this area oversee the development and implementation of new technologies and vehicle features.

- They collaborate with design and development teams to ensure projects meet technical requirements and are delivered on time.

2. Procurement:

- Supply chain managers play a critical role in project management by ensuring the timely and cost-effective delivery of parts and components.

- They collaborate with suppliers and internal stakeholders to optimize supply chain processes and mitigate risks.

3. Manufacturing:

- Project managers in manufacturing are responsible for coordinating and implementing process improvements and production line changes.

- They work closely with cross-functional teams to minimize disruptions and ensure efficient operations during project execution.

4. Quality Assurance:

- Quality control managers contribute to project management by ensuring that quality standards are met throughout the project lifecycle.

- They collaborate with project teams to identify and address quality issues, ensuring the final product meets customer expectations.

Cross Functional and Cross Departmental Projects:

Many of the project management roles in the automotive industry involve leading cross-functional and cross-departmental projects. These projects require collaboration and coordination between engineering, procurement, manufacturing, quality assurance, and other departments to ensure successful outcomes. Project managers in these roles need to facilitate effective communication, manage interdependencies, and align project goals across multiple functions and departments.

Project management roles play a pivotal role in the automotive industry, ensuring the successful realization of various initiatives. These roles are comprehensively outlined in both explicit and implicit job functions.

Explicit roles like project managers, program managers and PMO Leads take charge of organizing and executing cross-functional projects, managing multiple projects within a program, setting strategic directions, and overseeing the overall project management processes respectively.

Implicit roles like supply chain managers and quality control managers ensure a smooth supply of components for production and integrate quality management principles into project execution.

The origin of these roles can be traced back to different areas such as engineering, procurement, manufacturing, and quality assurance. Project managers in engineering help in the development of new technologies, supply chain managers in procurement ensure effective delivery of components, those in manufacturing coordinate process improvements, while quality control managers in quality assurance ensure that quality standards are adhered to.

Most importantly, project management in the automotive industry often involves managing cross-functional and cross-departmental projects. This requires collaboration and coordination across various departments like engineering, procurement, manufacturing, and quality assurance. For successful outcomes, project managers need to facilitate effective interdepartmental communication, manage dependencies and align project objectives across different functions.

Effective project management is central to the successful operation of a large automotive company. It ensures timely launches, process improvements, and high-quality standards that meet customer expectations and business goals. It is therefore crucial for decision-makers in the automotive industry to understand the importance of these roles and ensure they are properly filled and supported.

Analyzing Project Management Skills in the Automotive Industry

In the automotive industry, project management plays a crucial role in ensuring successful product development, manufacturing, and delivery. By analyzing job postings from the industry, we can identify the skills and positions that are closely related to project management. This analysis will provide insights into the explicit and implicit skills required for effective project management in the automotive sector.

Explicit Skills Related to Project Management:

1. Planning and Scheduling: Positions such as "Project Manager" and "Program Manager" explicitly mention the responsibility of creating and managing project plans, timelines, and schedules.

2. Budget Management: Many positions require skills in budget development, use tracking, and analysis to ensure projects are delivered within the allocated financial resources.

3. Stakeholder and Change Management: Job responsibilities often include collaborating with cross-functional teams, departments, and stakeholders to ensure smooth project execution and manage any changes that may arise.

Implicit Skills Related to Project Management:

1. Problem-Solving: While not explicitly mentioned in job descriptions, project managers in the automotive industry are expected to have strong problem-solving skills to identify issues, develop solutions, and implement corrective actions.

2. Leadership and Communication: Effective project management requires excellent leadership skills to motivate and guide teams. Effective communication skills are necessary to clearly convey project goals, objectives, and progress to stakeholders.

3. Risk Assessment and Mitigation: Project managers are responsible for identifying potential risks and developing strategies to mitigate them. This skill is important in the automotive industry to address uncertainties related to product development and manufacturing.

Areas from which Project Management Positions Come:

1. Operations: Positions related to project management often come from areas such as manufacturing, supply chain, and logistics, where project coordination and integration are essential.

2. Research and Development: Project management positions can also be found in R&D (Research & Development) departments to oversee new product development and innovation projects.

Cross-Functional and Cross-Departmental Projects:

Project managers in the automotive industry are often involved in cross-functional and cross-departmental projects. These projects require collaboration and coordination between various teams, including engineering, manufacturing, quality, procurement, and finance, to ensure the successful delivery of products.

Skills Not Obvious for Project Management but Important:

1. Technical Knowledge: While project management skills are vital, understanding technical aspects, such as automotive engineering and manufacturing processes, can enhance a project manager's effectiveness in decision-making and problem-solving.

2. Change Management: Given the dynamic nature of the automotive industry, project managers must possess skills in change management to adapt to evolving market conditions, regulations, and customer demands.

3. Quality Management: Understanding and implementing quality management principles and processes are crucial in ensuring that projects meet the required quality standards.

Project management in the automotive industry requires a combination of explicit skills such as planning, scheduling, and budget management, along with implicit skills like problem-solving, leadership, and risk assessment. Project managers often come from operations and R&D departments, and they are involved in cross-functional and cross-departmental projects. Technical knowledge, change management, and quality management are also essential skills for effective project management in the automotive sector.

Project management in the automotive industry is paramount, encompassing both explicit and implicit skills to ensure productive outcomes.

Explicit skills such as planning and scheduling, budget management, and stakeholder/change management are fundamental. As project managers, you must be adept at developing project plans, managing timelines, and staying within a budget. You will also work with various teams and stakeholders and manage any changes that occur during the project lifecycle.

Implicit skills also hold significant value. Problem-solving, for instance, is critical in identifying, addressing, and resolving project challenges. Leadership and communication are necessary in guiding teams and conveying project objectives effectively. Identifying potential risks and developing right mitigation strategies is also implicit in project management.

Project management roles typically emerge from operations (like manufacturing, supply chain) and Research and Development (R&D), requiring you to have a good understanding of these areas. Handling cross-functional and cross-departmental projects is common, involving coordination with teams like engineering, manufacturing, procurement, and finance.

Apart from these, some core skills do not typically stand out in project management but are incredibly important. Technical knowledge is one such skill; understanding automotive engineering and manufacturing processes is crucial to informed decision-making and problem-solving. Change management is another important skill due to the evolving nature of the automotive industry. Moreover, knowledge of quality management principles and processes is essential to ensure that projects meet specific quality standards.

Excellence in project management requires the right blend of explicit and implicit skills, technical knowledge, and adaptability, making it an integral part of the automotive industry’s success.

Project management is essential in the automotive industry for successful product development and delivery. Explicit project management positions include Project Managers, Program Managers, and PMO Leads, who are responsible for planning, budget management, stakeholder management, and change management. Implicit skills include problem-solving, leadership, communication, and risk assessment. Project management positions often originate from operations and R&D departments, and cross-functional and cross-departmental projects are common. Additional skills like technical knowledge, change management, and quality management are also important. Overall, project management is crucial to achieving business objectives in the automotive industry.

Analysis of Project Management Practices in the Automotive Industry

This section provides a comprehensive review and summary of a scientific publication. The focus is on the evaluation of Project Management (PM) implementations in the Original Equipment Manufacturing (OEM) sector of the automotive industry. The PM practices within various industries like aerospace and construction have proven to be effective in project success. These practices have led to better resource management and has resulted in increased concentration on strategic objectives. Despite such success, the implementation within the automotive industry, specifically within the OEM suppliers who are mostly small to medium-sized companies, is surprisingly low. As a result, the paper aims to explore the status of this PM implementation within the automotive

OEM industry, particularly in Italy. The methodology involved a survey sent to participants in this industry, from which gathered data was analyzed.

Redefining Project Management in the Automotive Industry with KanBo

In an analysis of advertisements published by companies in the automotive industry, it was revealed that Project Management was a significant theme, appearing in approximately 23% of the 1108 advertisements reviewed. The importance of this area cannot be emphasized enough - with Project Management entailing a broad range of tasks needing specific skill sets, it is centred on collaboration and coordination. As saw, a variety of methodologies and tools are employed within the sector to manage projects effectively. These include the Collaborative Scorecard, World Class Manufacturing, Total Quality Management (TQM), Advanced Product Quality Management (APQP), Lean Manufacturing, Matrix Organization, Simultaneous Engineering, and ISO-Technical Standard, among others.

However, a significant enhancement in project management can be achieved when companies in the automotive industry integrate the KanBo work coordination platform into their operations. The platform's versatility allows for seamless integration with the above-mentioned methodologies, translating to improved efficiency.

KanBo offers a collection of cards, or tasks, arranged in a highly customizable space, representing the workflow. With its in-built activity stream, you get a chronological list of all activities and updates related to a specific project. Its three-view feature allows you to switch between the Kanban, Gantt, and Timeline view basing on your needs at a particular moment. This, alongside KanBo's search and filter functions, allows for easy tracking and management of progress.

KanBo's feature of collaborative document editing, note-making, and bookmarking means all necessary project information is readily available, fostering efficient communication within teams. With the adoption of KanBo, project management within the automotive industry undergoes a transformation, becoming more streamlined, organized, and productive.

Harnessing Collaboration through the Collaborative Project Scorecard and KanBo in the Automotive Industry

The Collaborative Project Scorecard (CPS) is a project-focused modification of the Balanced Scorecard, devised to align project goals with business strategies whilst facilitating system integration management through a common vision and processes. The structure of CPS comprises three elements - levels, cause and effect relationships, and indicators, building upon the fundamentals of continuous communication, compliance, improvement, and cooperation. This scorecard has proven particularly effective in the automotive industry, where the dynamism of identifying significant Key Performance Indicators (KPIs) and project objectives correspond with cross-organizational strategies.

Incorporating the KanBo work coordination platform into CPS implementation offers several promising advantages in automotive project management. With features such as the activity stream, card details, and card activity stream, KanBo allows for comprehensive task tracking, efficient information logging, and easy access to project updates, respectively. A more personalized management approach can be created for each team member using the personal space view, granting them an individualized overview of their tasks within the project.

With the card user feature, delegation and assignment of tasks can be effectively managed as project leaders can see who is responsible for each task. Paired with the card status feature, project managers can also track the progress of each task. KanBo's notification feature further supports communication in the project, alerting team members of significant updates or changes in project status.

By merging the organization and clarity of the Collaborative Project Scorecard with the dynamic and interactive features of KanBo, automotive companies can significantly enhance their approach to project management.

Implementing World Class Manufacturing in the Automotive Industry with KanBo

World Class Manufacturing (WCM) is a holistic and systematic approach aimed at continuous improvement of processes and systems to reach optimal production standards. It integrates key methodologies such as Lean Manufacturing, Six Sigma, and Total Productive Maintenance, striving towards better, faster, and cheaper production while promoting agility in operations. In the automotive industry, WCM becomes an instrumental tool facilitating incessant communication and collaboration with both customers and suppliers.

Incorporating KanBo, a work coordination platform, into the WCM approach, can significantly boost project management standards in the automotive sector. With KanBo cards, tasks or projects can be managed effectively since they contain essential information such as notes, files, comments, dates, and checklists. These cards can then be grouped according to different criteria such as due dates or status, aiding in the organization of tasks.

The Kanban View feature allows visualization of a space divided into columns, reflecting the various stages of work in the project, characteristic of the lean approach in WCM. Additionally, the Mind Map view offers a graphical representation of relations between different tasks for better comprehension of project dependencies.