Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Implementing KanBo for Enhanced Maintenance Management in Automotive Industries

Best Practice

KanBo's comprehensive work coordination platform offers a robust solution tailored for managing maintenance tasks effectively in automotive industries.

This best practice aims to provide automotive companies with a pathway to leverage KanBo's functions to facilitate regular maintenance tasks on equipment, machinery, and facilities, and ensure they are in optimal working order.

Regular maintenance of equipment, machinery, and facilities is critical for automotive industries. By keeping them in optimal working condition, downtime is minimized, productivity is maximized, and costs are reduced.

Challenge

Despite its importance, managing maintenance tasks can be challenging. It involves scheduling regular checks, monitoring equipment status, addressing issues promptly, and ensuring all tasks are effectively communicated and completed by the right individuals. Traditional means of managing these tasks often lead to inefficiencies and miscommunication.

Solution

The KanBo platform offers several functions highly beneficial for automotive industries:

Activity Stream

Allows tracking of all maintenance activities, updates, and changes in real time.

Calendar View

Offers a clear visualization of scheduled maintenance tasks.

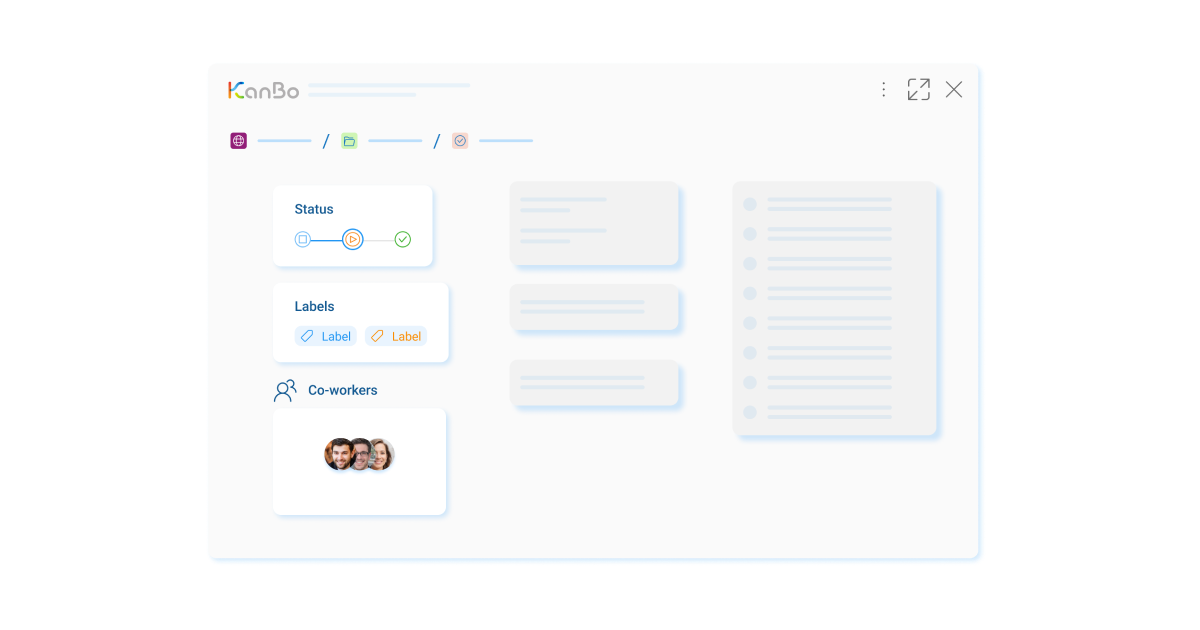

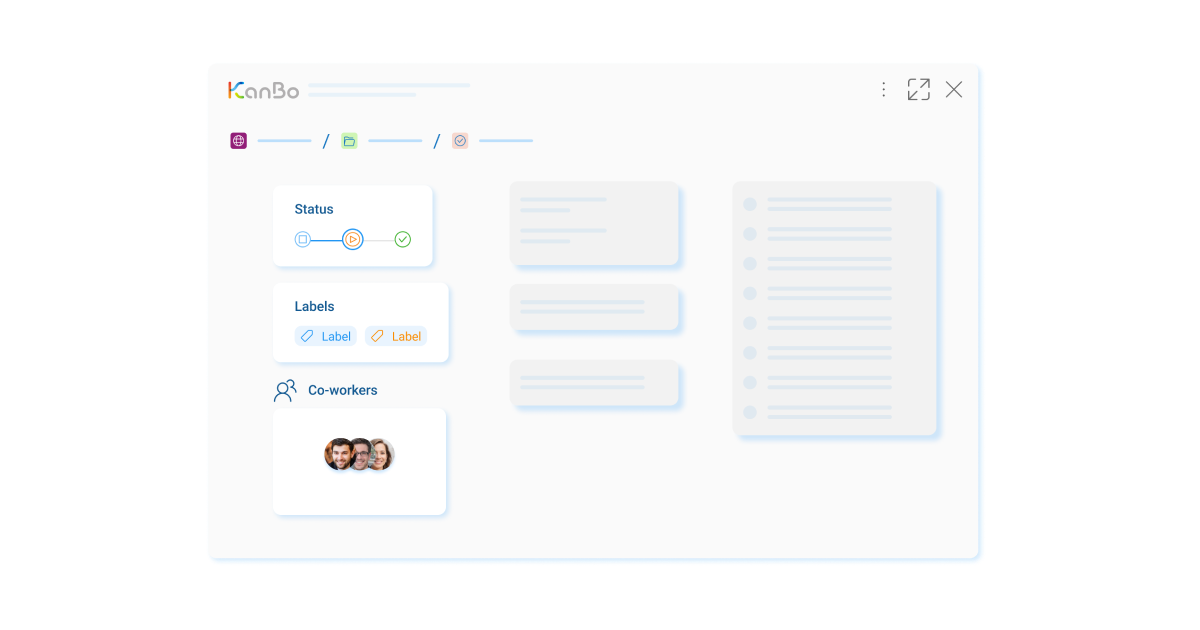

Card features

Create specific cards for each maintenance task, attach necessary documents, and assign them to the responsible individuals.

Notifications

Ensure all stakeholders are updated about task progress and upcoming maintenance schedules in real time.

These features provide automotive industries a comprehensive overview of maintenance activities. They enable real-time tracking, effective task delegation, clear communication, and prompt issue resolution, reducing inefficiencies and costs.

Daily Routine

Maintenance tasks are scheduled in Calendar View and assigned to responsible individuals. Updates and changes are made to the Card and are instantly reflected in the Activity Stream. Notifications ensure that all stakeholders are constantly informed and aligned.

Use Case

Consider an automotive company that experiences frequent machine downtime due to haphazard maintenance schedules. By incorporating KanBo into their daily operations, the company can regulate their maintenance schedule, ensure timely completion of tasks, and drastically reduce machine downtime.

KanBo Tips

Explore the various functionalities of KanBo to customize the platform to best suit your company's needs. Always keep stakeholders informed about maintenance schedules and updates through KanBo's notification function.

Experience how KanBo can revolutionize your maintenance management in the Automotive industry. Start your journey with KanBo for Automotive today!

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Implementing KanBo for Enhanced Maintenance Management in Automotive Industries

Best Practice

KanBo's comprehensive work coordination platform offers a robust solution tailored for managing maintenance tasks effectively in automotive industries.

This best practice aims to provide automotive companies with a pathway to leverage KanBo's functions to facilitate regular maintenance tasks on equipment, machinery, and facilities, and ensure they are in optimal working order.

Regular maintenance of equipment, machinery, and facilities is critical for automotive industries. By keeping them in optimal working condition, downtime is minimized, productivity is maximized, and costs are reduced.

Challenge

Despite its importance, managing maintenance tasks can be challenging. It involves scheduling regular checks, monitoring equipment status, addressing issues promptly, and ensuring all tasks are effectively communicated and completed by the right individuals. Traditional means of managing these tasks often lead to inefficiencies and miscommunication.

Solution

The KanBo platform offers several functions highly beneficial for automotive industries:

Activity Stream

Allows tracking of all maintenance activities, updates, and changes in real time.

Calendar View

Offers a clear visualization of scheduled maintenance tasks.

Card features

Create specific cards for each maintenance task, attach necessary documents, and assign them to the responsible individuals.

Notifications

Ensure all stakeholders are updated about task progress and upcoming maintenance schedules in real time.

These features provide automotive industries a comprehensive overview of maintenance activities. They enable real-time tracking, effective task delegation, clear communication, and prompt issue resolution, reducing inefficiencies and costs.

Daily Routine

Maintenance tasks are scheduled in Calendar View and assigned to responsible individuals. Updates and changes are made to the Card and are instantly reflected in the Activity Stream. Notifications ensure that all stakeholders are constantly informed and aligned.

Use Case

Consider an automotive company that experiences frequent machine downtime due to haphazard maintenance schedules. By incorporating KanBo into their daily operations, the company can regulate their maintenance schedule, ensure timely completion of tasks, and drastically reduce machine downtime.

KanBo Tips

Explore the various functionalities of KanBo to customize the platform to best suit your company's needs. Always keep stakeholders informed about maintenance schedules and updates through KanBo's notification function.

Experience how KanBo can revolutionize your maintenance management in the Automotive industry. Start your journey with KanBo for Automotive today!