Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Streamlining Manufacturing Execution Systems Across Multiple Plants

What do you need to know about this challenge?

A significant challenge in the automotive industry, especially when overseeing multiple manufacturing plants, is the implementation and management of an effective manufacturing execution system, like ActivPlant, across all regional plants. This system should ensure that processes are robust, repeatable, and controlled to maximize business value and enhance plant characteristics. However, maintaining standardization and ensuring diffusion of the system across all plants can be complex and intricate, requiring considerable planning, organizing, and supervision.

What can you do with KanBo to solve this challenge?

KanBo, an all-encompassing project management and real-time collaboration tool, provides multiple features to help you address this challenge:

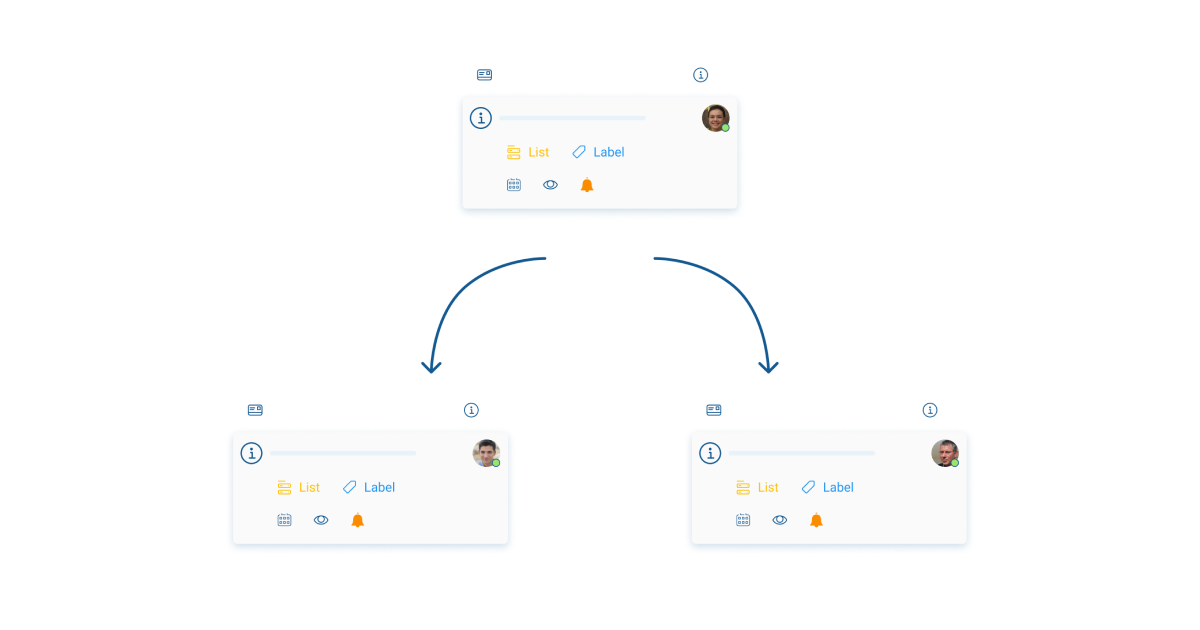

- Space: You can set up individual 'spaces' for each manufacturing plant, enabling efficient tracking and management of their respective execution systems.

- Card: Represent different system tasks or processes using ‘cards’. Cards can help make sense of the complex processes in such systems.

- Card Status: Cards can be assigned statuses to indicate their current stage or condition, providing clarity on progress in different stages of system implementation.

- To-Do Lists: Break down larger tasks into 'to-do lists' within cards, making it easier to manage and track progress.

- Activity Stream: Monitor 'activity streams' to maintain a real-time log of all activities and updates related to a particular task or process.

- Card Blocker: Use the 'card blocker' feature to identify any issues or obstacles preventing progression of a task or process.

- Document Folder: Utilize 'document folders' to attach important files or documents directly to the respective card, making information readily accessible.

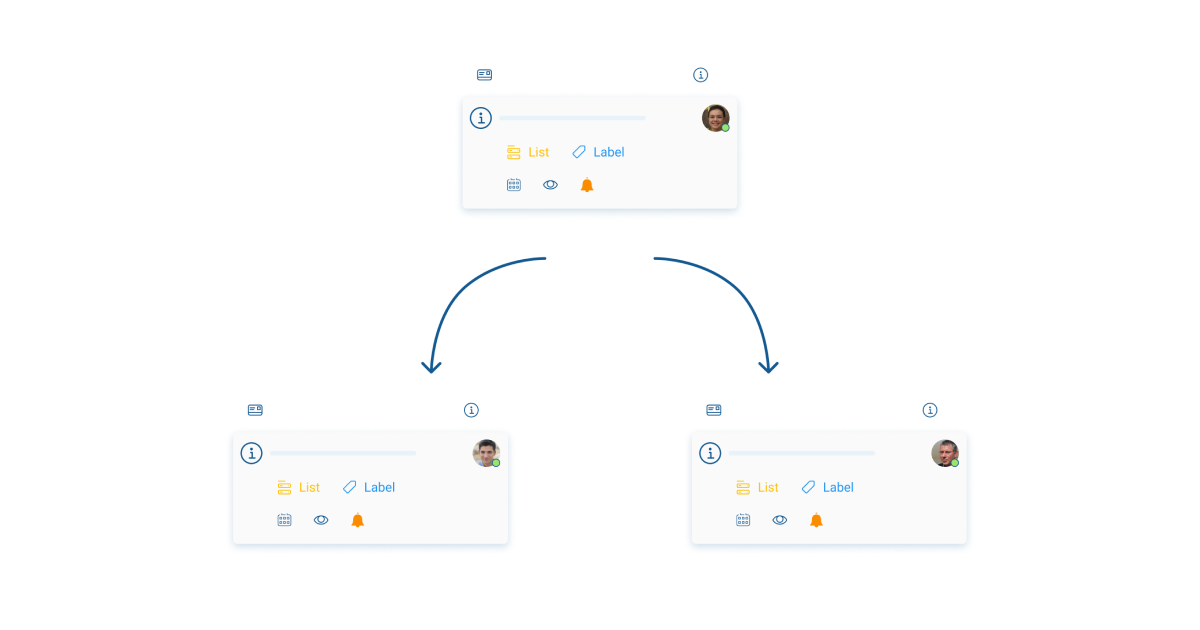

- Card Relation: Outline dependencies and relations between tasks using the ‘card relations’ feature.

What can you expect after solving this challenge?

With KanBo, you can expect a streamlined process for the implementation and management of your manufacturing execution system across different regional plants. This will not only lead to standardized and robust processes but also reduce inefficiencies and miscommunications. Long-term benefits include enhanced visibility into the manufacturing processes, simplified decision-making and improved resource allocation. In the future, KanBo could be integrated with your manufacturing execution system, providing a consolidated and comprehensive solution for managing all aspects of your manufacturing operation. All of this will ultimately contribute to maximizing business value and enhancing the plant's characteristics uniformly across all locations.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Streamlining Manufacturing Execution Systems Across Multiple Plants

What do you need to know about this challenge?

A significant challenge in the automotive industry, especially when overseeing multiple manufacturing plants, is the implementation and management of an effective manufacturing execution system, like ActivPlant, across all regional plants. This system should ensure that processes are robust, repeatable, and controlled to maximize business value and enhance plant characteristics. However, maintaining standardization and ensuring diffusion of the system across all plants can be complex and intricate, requiring considerable planning, organizing, and supervision.

What can you do with KanBo to solve this challenge?

KanBo, an all-encompassing project management and real-time collaboration tool, provides multiple features to help you address this challenge:

- Space: You can set up individual 'spaces' for each manufacturing plant, enabling efficient tracking and management of their respective execution systems.

- Card: Represent different system tasks or processes using ‘cards’. Cards can help make sense of the complex processes in such systems.

- Card Status: Cards can be assigned statuses to indicate their current stage or condition, providing clarity on progress in different stages of system implementation.

- To-Do Lists: Break down larger tasks into 'to-do lists' within cards, making it easier to manage and track progress.

- Activity Stream: Monitor 'activity streams' to maintain a real-time log of all activities and updates related to a particular task or process.

- Card Blocker: Use the 'card blocker' feature to identify any issues or obstacles preventing progression of a task or process.

- Document Folder: Utilize 'document folders' to attach important files or documents directly to the respective card, making information readily accessible.

- Card Relation: Outline dependencies and relations between tasks using the ‘card relations’ feature.

What can you expect after solving this challenge?

With KanBo, you can expect a streamlined process for the implementation and management of your manufacturing execution system across different regional plants. This will not only lead to standardized and robust processes but also reduce inefficiencies and miscommunications. Long-term benefits include enhanced visibility into the manufacturing processes, simplified decision-making and improved resource allocation. In the future, KanBo could be integrated with your manufacturing execution system, providing a consolidated and comprehensive solution for managing all aspects of your manufacturing operation. All of this will ultimately contribute to maximizing business value and enhancing the plant's characteristics uniformly across all locations.