Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Efficient System Standardization and Management

The Challenge: Enhancing Regional Computerized Operation System

In the landscape of modern industrial manufacturing plants, a compelling challenge lies in regional process system management. The industrial leader has to spearhead the steering of regional computerized operation systems, ensure standardization across manufacturing plants and maximize the business value. Balancing the need for both consistency in operations and adaptability to plant-specific attributes forms the core of this task. The objective is to ensure robust, controllable and repeatable processes that enhance the overall effectiveness of the plant operations.

The KanBo Solution: Streamlining Operations and Enhancing System Standardization

To effectively combat this challenge, the comprehensive project management and collaboration tool, KanBo, brings several robust features to the table:

- Spaces: Creating dedicated spaces for different plants or regions facilitates the centralized yet tailored operation standardization.

- Card: By representing different components of the regional process systems with cards, management of individual units becomes seamless and efficient.

- Card Grouping: The ability to categorize and group cards based on requirements helps in classifying different system components effectively.

- Card Status: Tracking the progress of each task becomes effortless with card status. This feature ensures transparent communication and progress tracking.

- Document Folder: Attaching relevant documents and guidelines to the task cards provide easy access to vital information for team members.

- Activity Streams: Real-time updates of every task, its status and recent changes in activity streams smoothen internal communication and boost intra-team collaboration.

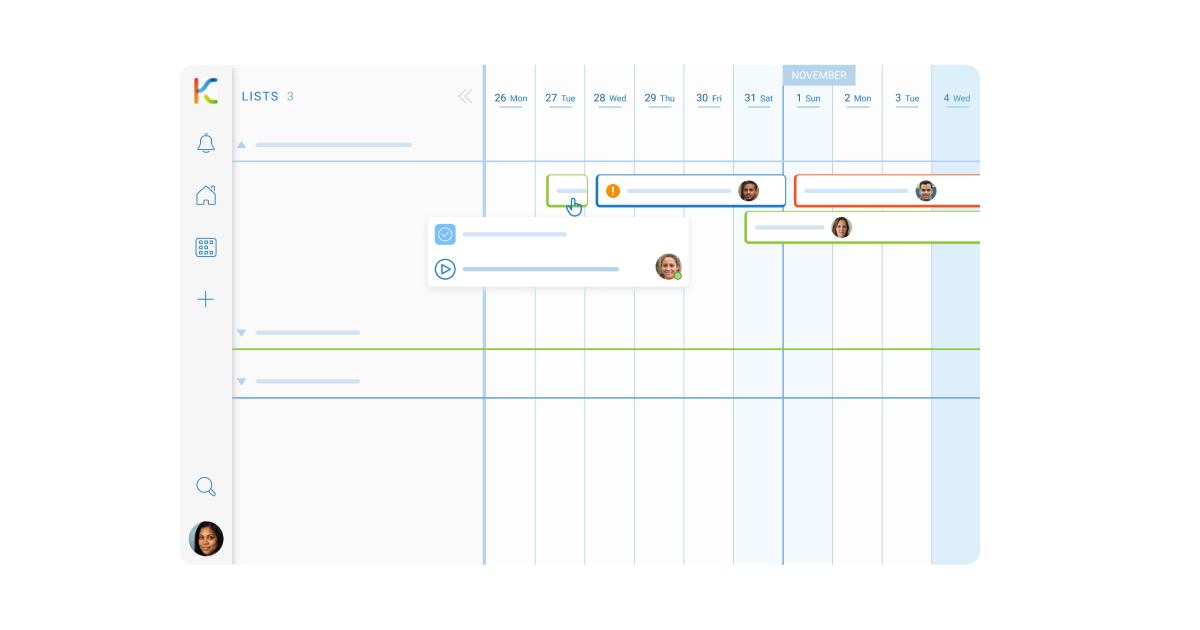

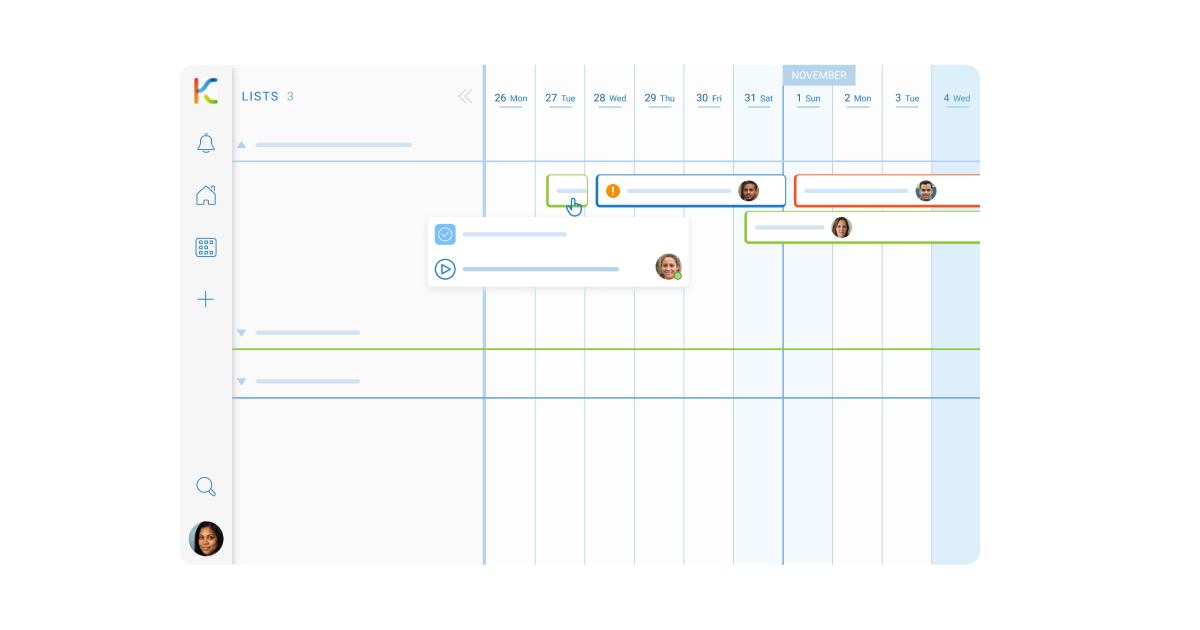

- Timeline View: This feature helps in tracking the progress of tasks over time. It ensures that the entire operation system is in sync with production timelines.

The Result: Streamlined Operations and Enhanced Business Value

By employing the versatile features of KanBo, the challenge of regional process system management can be mitigated effectively. Immediate benefits would be improved standardization, resulting in an efficient operational process and increased business value. Aiding this would be enhanced communication and streamlined collaboration among team members of different plants, further improving the overall operational efficiency.

In the long run, beyond the immediate benefits, the transparency in operation management will foster a healthy work culture and ensure the better performance of every plant unit. Future improvements could involve tightening integration with existing system tools used in plants for a more comprehensive solution.

By implementing KanBo, industry leaders can ensure that regional computerized operation systems remain a source of business value and operational excellence, rather than a challenge.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Efficient System Standardization and Management

The Challenge: Enhancing Regional Computerized Operation System

In the landscape of modern industrial manufacturing plants, a compelling challenge lies in regional process system management. The industrial leader has to spearhead the steering of regional computerized operation systems, ensure standardization across manufacturing plants and maximize the business value. Balancing the need for both consistency in operations and adaptability to plant-specific attributes forms the core of this task. The objective is to ensure robust, controllable and repeatable processes that enhance the overall effectiveness of the plant operations.

The KanBo Solution: Streamlining Operations and Enhancing System Standardization

To effectively combat this challenge, the comprehensive project management and collaboration tool, KanBo, brings several robust features to the table:

- Spaces: Creating dedicated spaces for different plants or regions facilitates the centralized yet tailored operation standardization.

- Card: By representing different components of the regional process systems with cards, management of individual units becomes seamless and efficient.

- Card Grouping: The ability to categorize and group cards based on requirements helps in classifying different system components effectively.

- Card Status: Tracking the progress of each task becomes effortless with card status. This feature ensures transparent communication and progress tracking.

- Document Folder: Attaching relevant documents and guidelines to the task cards provide easy access to vital information for team members.

- Activity Streams: Real-time updates of every task, its status and recent changes in activity streams smoothen internal communication and boost intra-team collaboration.

- Timeline View: This feature helps in tracking the progress of tasks over time. It ensures that the entire operation system is in sync with production timelines.

The Result: Streamlined Operations and Enhanced Business Value

By employing the versatile features of KanBo, the challenge of regional process system management can be mitigated effectively. Immediate benefits would be improved standardization, resulting in an efficient operational process and increased business value. Aiding this would be enhanced communication and streamlined collaboration among team members of different plants, further improving the overall operational efficiency.

In the long run, beyond the immediate benefits, the transparency in operation management will foster a healthy work culture and ensure the better performance of every plant unit. Future improvements could involve tightening integration with existing system tools used in plants for a more comprehensive solution.

By implementing KanBo, industry leaders can ensure that regional computerized operation systems remain a source of business value and operational excellence, rather than a challenge.