Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Effective Equipment Introduction and Implementation - Tackling the Balancing Act in Automotive Manufacturing

What do you need to know about this challenge?

One of the significant challenges in the automotive industry is the role of a Process/ Equipment Engineer. This challenge emerges conspicuously in large automotive corporations where the engineer has to carry out the complex process of introducing and implementing equipment for new model introduction across several facilities. Simultaneously, they have to balance between maintaining quality, controlling costs, and ensuring safety. This balancing act is indeed complex and necessitates a clear and effective solution.

What can you do with KanBo to solve this challenge?

KanBo, a comprehensive project and collaboration tool, offers several features that help in overcoming this challenge:

- Activity Stream: Maintain a real-time log of actions performed, offering transparency on what happened, when, and who did it. This facilitates effective tracking of equipment introduction and implementation process.

- Space: Create separate 'spaces' for different departments involved in the process. This ensures that all task-specific data and discussions are in one place, making cross-departmental collaboration easier.

- Cards: Use KanBo 'cards' to represent various tasks in the process. Assign details such as tasks, deadlines, and relevant personnel to these cards, ensuring that every member of the team stays on the same page.

- Calendar view: Use this feature to schedule and keep track of all important tasks and deadlines. This allows you to manage timelines effectively and keep the implementation process on schedule.

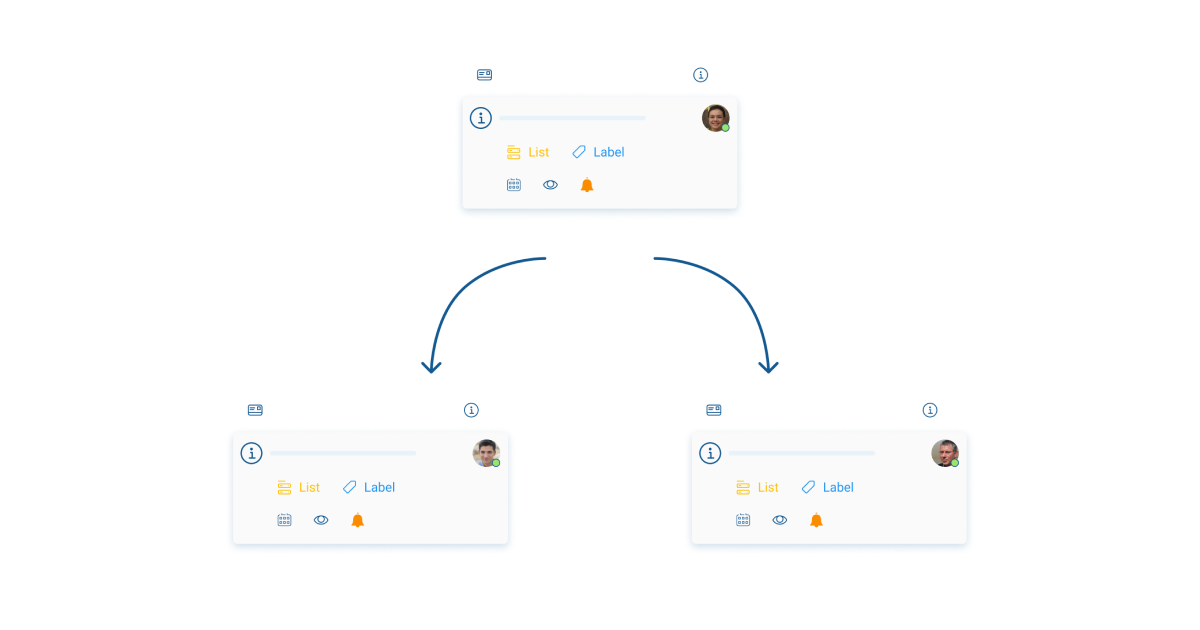

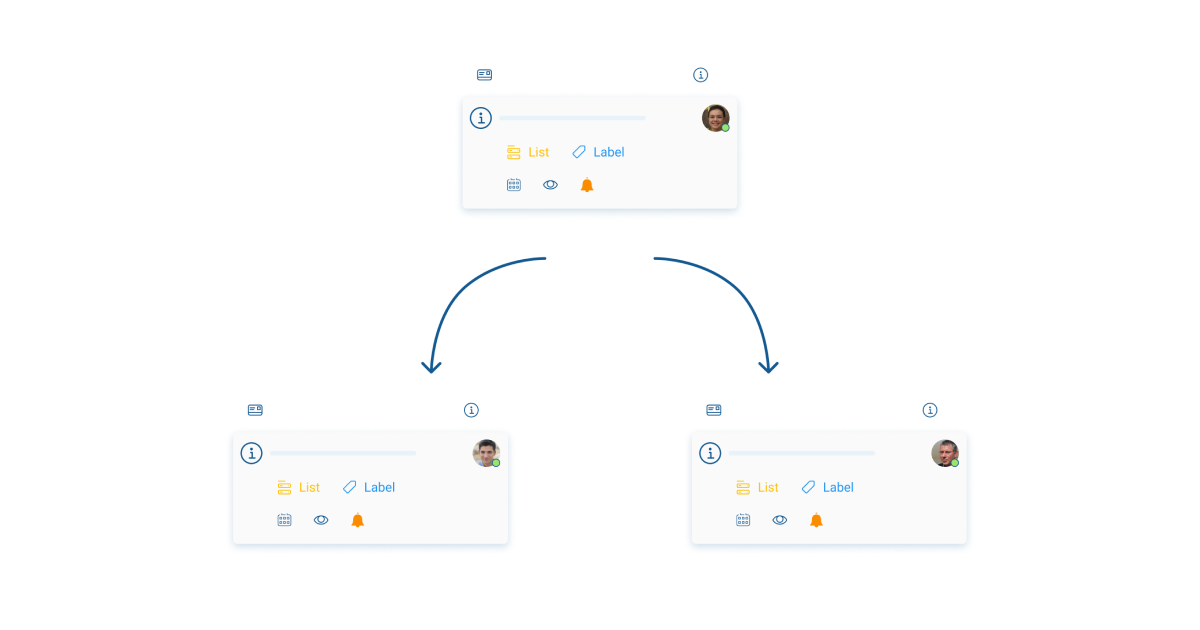

- Card Relations: This feature allows you to establish connections between different tasks (cards). It aids in understanding the interdependencies of various stages of the equipment introduction process, allowing for sequential and organized execution.

What can you expect after solving this challenge?

With the effective use of KanBo to manage such complex tasks, you can expect improved organization, streamlined operations, and enhanced team collaboration. In the long run, these improvements should lead to more efficient decision-making and implementation processes, which in turn would speed up time-to-market. Additionally, the use of KanBo promotes a culture of transparency and accountability within the team. Future enhancements could include integration with advanced manufacturing and process management software, providing a more comprehensive solution to tackle the challenge. Ultimately, with KanBo, the Process/ Equipment Engineers can focus on their core work while ensuring that the processes are carried out smoothly and effectively.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Effective Equipment Introduction and Implementation - Tackling the Balancing Act in Automotive Manufacturing

What do you need to know about this challenge?

One of the significant challenges in the automotive industry is the role of a Process/ Equipment Engineer. This challenge emerges conspicuously in large automotive corporations where the engineer has to carry out the complex process of introducing and implementing equipment for new model introduction across several facilities. Simultaneously, they have to balance between maintaining quality, controlling costs, and ensuring safety. This balancing act is indeed complex and necessitates a clear and effective solution.

What can you do with KanBo to solve this challenge?

KanBo, a comprehensive project and collaboration tool, offers several features that help in overcoming this challenge:

- Activity Stream: Maintain a real-time log of actions performed, offering transparency on what happened, when, and who did it. This facilitates effective tracking of equipment introduction and implementation process.

- Space: Create separate 'spaces' for different departments involved in the process. This ensures that all task-specific data and discussions are in one place, making cross-departmental collaboration easier.

- Cards: Use KanBo 'cards' to represent various tasks in the process. Assign details such as tasks, deadlines, and relevant personnel to these cards, ensuring that every member of the team stays on the same page.

- Calendar view: Use this feature to schedule and keep track of all important tasks and deadlines. This allows you to manage timelines effectively and keep the implementation process on schedule.

- Card Relations: This feature allows you to establish connections between different tasks (cards). It aids in understanding the interdependencies of various stages of the equipment introduction process, allowing for sequential and organized execution.

What can you expect after solving this challenge?

With the effective use of KanBo to manage such complex tasks, you can expect improved organization, streamlined operations, and enhanced team collaboration. In the long run, these improvements should lead to more efficient decision-making and implementation processes, which in turn would speed up time-to-market. Additionally, the use of KanBo promotes a culture of transparency and accountability within the team. Future enhancements could include integration with advanced manufacturing and process management software, providing a more comprehensive solution to tackle the challenge. Ultimately, with KanBo, the Process/ Equipment Engineers can focus on their core work while ensuring that the processes are carried out smoothly and effectively.