Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Streamlining Delivery Through Standardized Templates

Best Practice

In the dynamic operations of the automotive industry, the efficiency of a task depends largely on its standardization. As such, when dealing with recurrent processes like vehicle assembly, quality control checks, and supply chain management, certain patterns and routines become noticeable and can be documented into templates for future use. This practice of utilizing templates fosters uniformity, saves time taken in initiating processes from scratch, reduces the chances of mistakes, and ensures constancy in the final output.

Carving Efficiency through Standardized Templates in Automotive Industry Operations

In the pursuit of efficiency and cost-effectiveness in the automotive industry, one thing stands paramount; Standardization. Recurring processes are the backbone of the industry. Whether it's vehicle assembly, ensuring quality control, or managing the supply chain, these processes take place recurrently, hence highlighting the need for uniformity and consistency. It is against this backdrop, that the importance of streamlining deliveries through templates is highlighted.

Challenge

Coming up with a new approach for each recurring process consumes valuable time and predisposes the output to inconsistencies and irregularities.

Solution

Being in an environment where tasks such as quality control checks and supply chain management recur frequently, the time saved by using templates instead of initiating these processes from scratch each time can be significant. Besides, the use of templates ensures there is a standardized procedure to follow, minimizing the chances of errors or discrepancies.

Utilize Card Templates

KanBo's ‘card template’ functionality is a predetermined and reusable layout for creating cards, which represent tasks in the workflow process. These templates come in handy and save a lot of effort in creating new cards for each recurrent process.

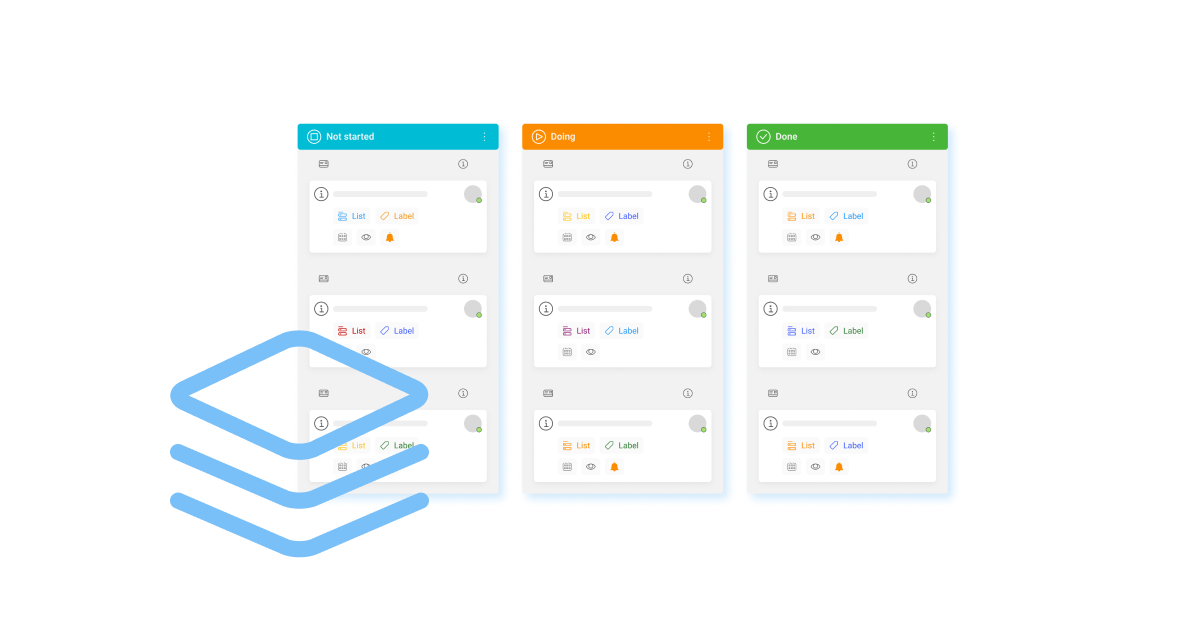

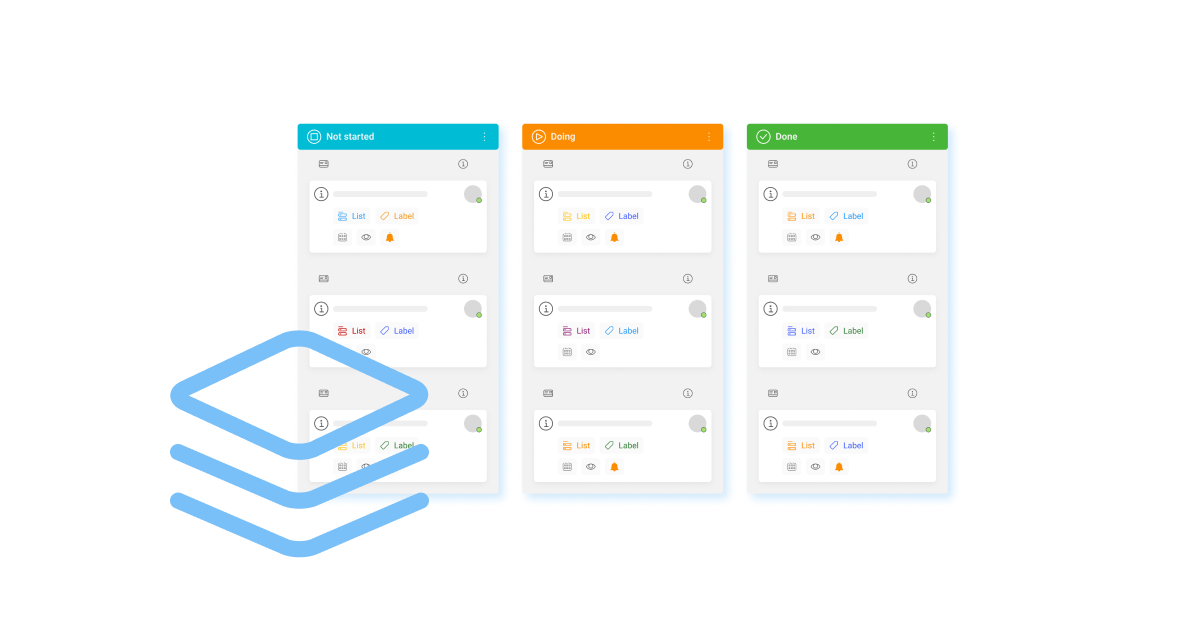

Implement Space Templates

KanBo's ‘space template’ is a preconfigured layout for creating spaces (projects or area of focus). These predefined card groupings, elements, and statuses facilitate consistency and efficiency in creation and management of new spaces.

Daily Routine

- Use a card template: whenever a new task such as quality control check comes up, instead of starting from scratch, the team can use a pre-existing car template to streamline the workflow process.

- Employ space templates: use space templates to structure and organize your project effectively.

Use Case

For example, if there is a frequent task of running quality control checks on finished products within the assembly line, instead of creating a new task card each time, a standardized card template can be used to initiate the task with all fields pre-filled as per the requirements of the task.

KanBo Tips

- Make good use of card templates for recurring tasks within your workflow. Not only do they save time, but they also ensure consistency in how tasks are performed.

- Space templates are your go-to for organizing your tasks and projects. They allow you to categorize your tasks effectively which makes management easier.

Get started on creating a more efficient and streamlined product design process today with KanBo for Automotive.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Streamlining Delivery Through Standardized Templates

Best Practice

In the dynamic operations of the automotive industry, the efficiency of a task depends largely on its standardization. As such, when dealing with recurrent processes like vehicle assembly, quality control checks, and supply chain management, certain patterns and routines become noticeable and can be documented into templates for future use. This practice of utilizing templates fosters uniformity, saves time taken in initiating processes from scratch, reduces the chances of mistakes, and ensures constancy in the final output.

Carving Efficiency through Standardized Templates in Automotive Industry Operations

In the pursuit of efficiency and cost-effectiveness in the automotive industry, one thing stands paramount; Standardization. Recurring processes are the backbone of the industry. Whether it's vehicle assembly, ensuring quality control, or managing the supply chain, these processes take place recurrently, hence highlighting the need for uniformity and consistency. It is against this backdrop, that the importance of streamlining deliveries through templates is highlighted.

Challenge

Coming up with a new approach for each recurring process consumes valuable time and predisposes the output to inconsistencies and irregularities.

Solution

Being in an environment where tasks such as quality control checks and supply chain management recur frequently, the time saved by using templates instead of initiating these processes from scratch each time can be significant. Besides, the use of templates ensures there is a standardized procedure to follow, minimizing the chances of errors or discrepancies.

Utilize Card Templates

KanBo's ‘card template’ functionality is a predetermined and reusable layout for creating cards, which represent tasks in the workflow process. These templates come in handy and save a lot of effort in creating new cards for each recurrent process.

Implement Space Templates

KanBo's ‘space template’ is a preconfigured layout for creating spaces (projects or area of focus). These predefined card groupings, elements, and statuses facilitate consistency and efficiency in creation and management of new spaces.

Daily Routine

- Use a card template: whenever a new task such as quality control check comes up, instead of starting from scratch, the team can use a pre-existing car template to streamline the workflow process.

- Employ space templates: use space templates to structure and organize your project effectively.

Use Case

For example, if there is a frequent task of running quality control checks on finished products within the assembly line, instead of creating a new task card each time, a standardized card template can be used to initiate the task with all fields pre-filled as per the requirements of the task.

KanBo Tips

- Make good use of card templates for recurring tasks within your workflow. Not only do they save time, but they also ensure consistency in how tasks are performed.

- Space templates are your go-to for organizing your tasks and projects. They allow you to categorize your tasks effectively which makes management easier.

Get started on creating a more efficient and streamlined product design process today with KanBo for Automotive.