Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo and the Maintenance Technician (Mechatronics) in Pharmaceuticals: Collaborating for Optimal Equipment Efficiency

What do you need to know about this challenge?

In the realm of pharmaceuticals, a Maintenance Technician (Mechatronics) is often confronted with the vital task of cross-team coordination to ensure the reliability and efficiency of complex equipment. This challenge is characterized by the necessity to conduct maintenance, troubleshooting, and improvement measures while meticulously documenting processes and collaborating with various team members to minimize equipment downtime and enhance productivity.

What can you do with KanBo to solve this challenge?

KanBo empowers Maintenance Technicians (Mechatronics) with a suite of tools designed to streamline collaboration and equipment management:

- Centralized Documentation: Utilize KanBo’s document source to centralize technical manuals and maintenance procedures, ensuring easy access and adherence to protocols.

- Workflow Management: Implement Grouping to organize maintenance tasks by machinery type or urgency level, improving oversight and prioritization of critical issues.

- Real-Time Updates: Benefit from the user activity stream to stay informed about team actions and updates, fostering real-time communication and quick responses.

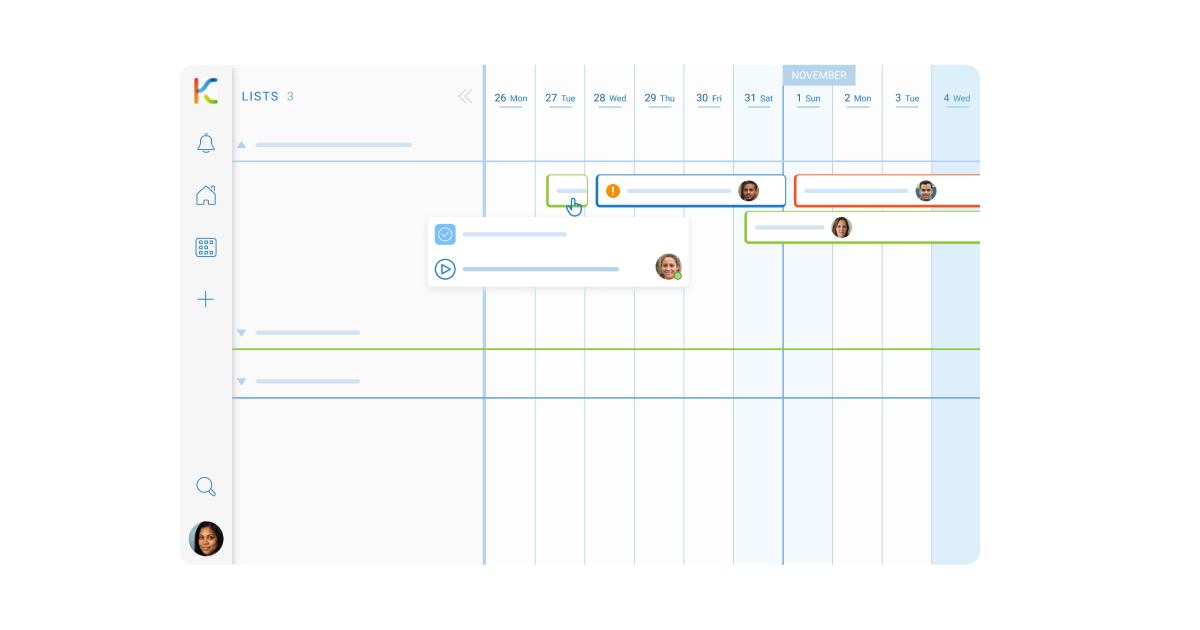

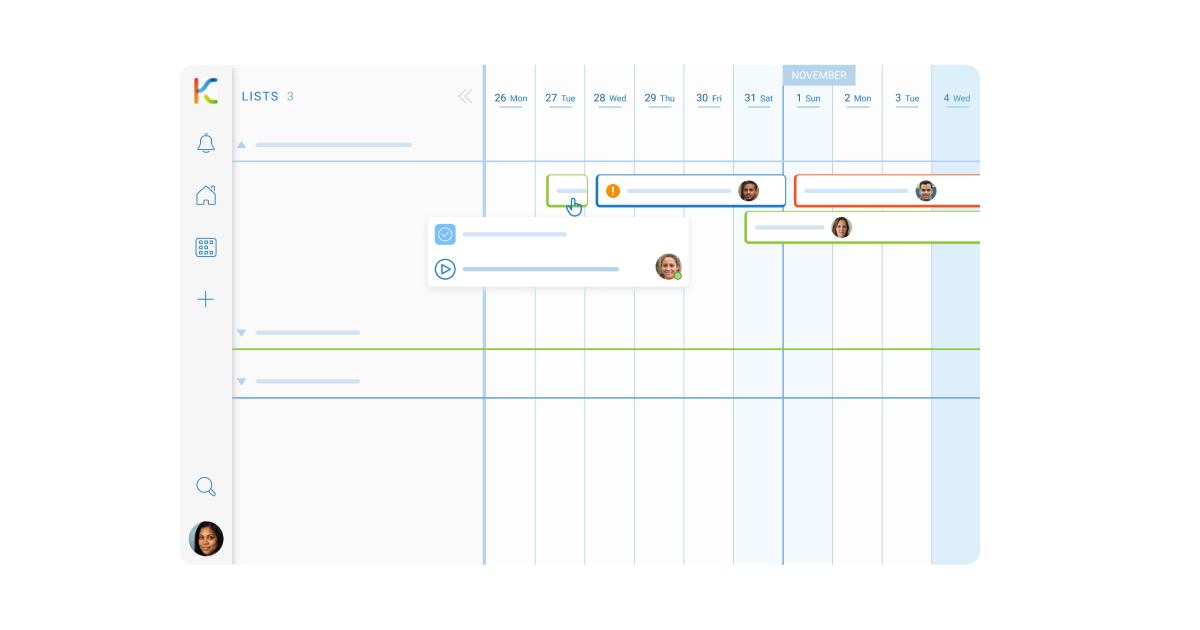

- Task Scheduling: Employ the Timeline view to schedule preventive maintenance tasks and track progress over time, ensuring timely execution and historical referencing.

- Performance Tracking: Use the KanBo Search to quickly retrieve past maintenance records, performance logs, or downtime incidents for analysis and reporting.

- Detailed Analysis: Analyze maintenance cycles and team efficiency with the Gantt Chart view, enabling a clear visual of timelines and workload distribution.

What can you expect after solving this challenge?

By leveraging KanBo's features to tackle the collaboration challenge in pharmaceutical maintenance, technicians can expect transformative outcomes. Enhanced visibility into team tasks will drive better coordination and quicker turnaround times. Structured and documented workflows foster a culture of accountability and continuous improvement, with reduced incidents of unexpected downtime. Over time, the predictive power enabled by diligent record keeping and analysis could lead to refined maintenance strategies, ultimately contributing to higher equipment longevity and lower operational costs. As the industry evolves, KanBo's versatile tools will remain ready to adapt to changing maintenance and collaboration needs, solidifying its role as an essential asset for any Maintenance Technician (Mechatronics).

Table of Contents

KanBo – The Pharma-Focused Work Coordination Maestro

Experience ultimate task alignment, communication and collaboration

Trusted globally, KanBo, bridges the gap between management and engineering in complex pharmaceutical organizations. Seamless coordination, advanced project planning, and outstanding leadership are made possible through our versatile software. Stride toward your mission-critical goals with superior collaboration and communication.

KanBo and the Maintenance Technician (Mechatronics) in Pharmaceuticals: Collaborating for Optimal Equipment Efficiency

What do you need to know about this challenge?

In the realm of pharmaceuticals, a Maintenance Technician (Mechatronics) is often confronted with the vital task of cross-team coordination to ensure the reliability and efficiency of complex equipment. This challenge is characterized by the necessity to conduct maintenance, troubleshooting, and improvement measures while meticulously documenting processes and collaborating with various team members to minimize equipment downtime and enhance productivity.

What can you do with KanBo to solve this challenge?

KanBo empowers Maintenance Technicians (Mechatronics) with a suite of tools designed to streamline collaboration and equipment management:

- Centralized Documentation: Utilize KanBo’s document source to centralize technical manuals and maintenance procedures, ensuring easy access and adherence to protocols.

- Workflow Management: Implement Grouping to organize maintenance tasks by machinery type or urgency level, improving oversight and prioritization of critical issues.

- Real-Time Updates: Benefit from the user activity stream to stay informed about team actions and updates, fostering real-time communication and quick responses.

- Task Scheduling: Employ the Timeline view to schedule preventive maintenance tasks and track progress over time, ensuring timely execution and historical referencing.

- Performance Tracking: Use the KanBo Search to quickly retrieve past maintenance records, performance logs, or downtime incidents for analysis and reporting.

- Detailed Analysis: Analyze maintenance cycles and team efficiency with the Gantt Chart view, enabling a clear visual of timelines and workload distribution.

What can you expect after solving this challenge?

By leveraging KanBo's features to tackle the collaboration challenge in pharmaceutical maintenance, technicians can expect transformative outcomes. Enhanced visibility into team tasks will drive better coordination and quicker turnaround times. Structured and documented workflows foster a culture of accountability and continuous improvement, with reduced incidents of unexpected downtime. Over time, the predictive power enabled by diligent record keeping and analysis could lead to refined maintenance strategies, ultimately contributing to higher equipment longevity and lower operational costs. As the industry evolves, KanBo's versatile tools will remain ready to adapt to changing maintenance and collaboration needs, solidifying its role as an essential asset for any Maintenance Technician (Mechatronics).