Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Quality Control in Automotive Battery Manufacturing

What do you need to know about this challenge?

In the fast-paced world of automotive manufacturing, one of the significant challenges is maintaining stringent quality control standards. This becomes notably prominent in the role of a Quality Engineer Technician at a battery manufacturing plant. Here, the challenge is twofold. Firstly, the technician needs to ensure all manufacturing processes are managed within set control requirements. Secondly, there is a need for detailed analyses of any cells/modules that fall out of these control limits, ensuring that only top-grade products reach the clients. This task requires careful attention to detail, effective data handling, and strong problem-solving skills while working in conjunction with different departments to enhance product quality.

What can you do with KanBo to solve this challenge?

KanBo's comprehensive array of features provides a robust solution to tackle these challenges:

- Space: Create separate spaces for individual processes. This segregation allows monitoring each process distinctly, facilitating efficient management.

- Card: Use cards to represent different tasks within each process. Cards can be used to identify tasks requiring special attention or any process falling outside the control limits.

- Activity Stream: The Activity Stream provides real-time updates of each process, keeping everyone informed and ensuring transparency across all stages.

- Card Status: Update Card Status regularly to keep track of task progression. This helps in quick identification of any issue that needs immediate attention.

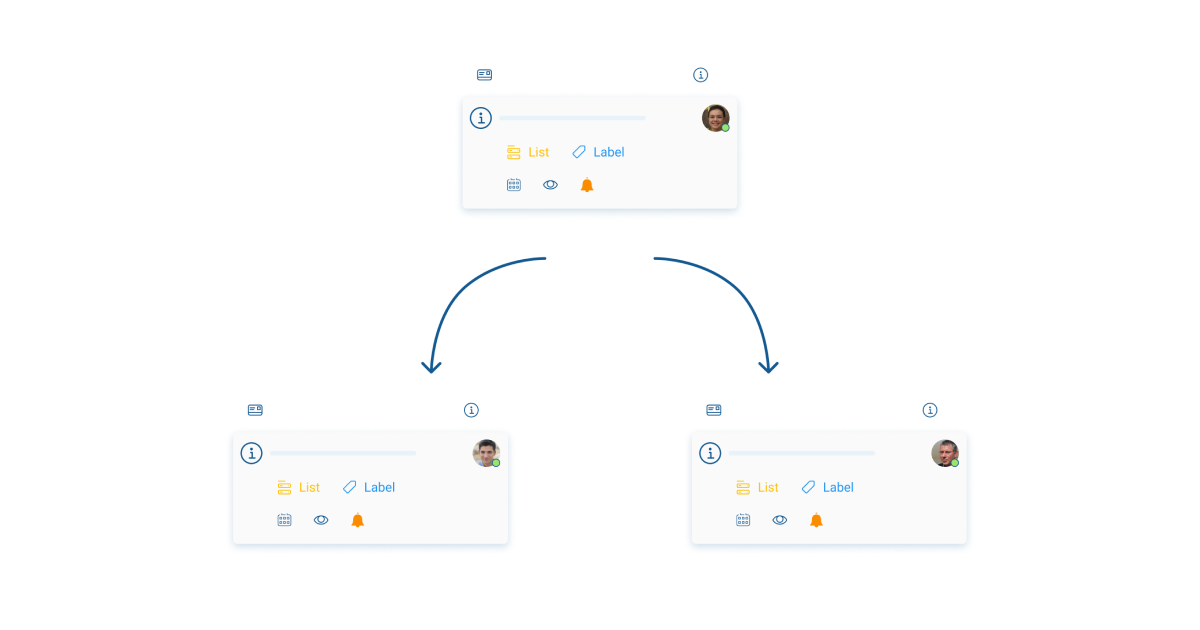

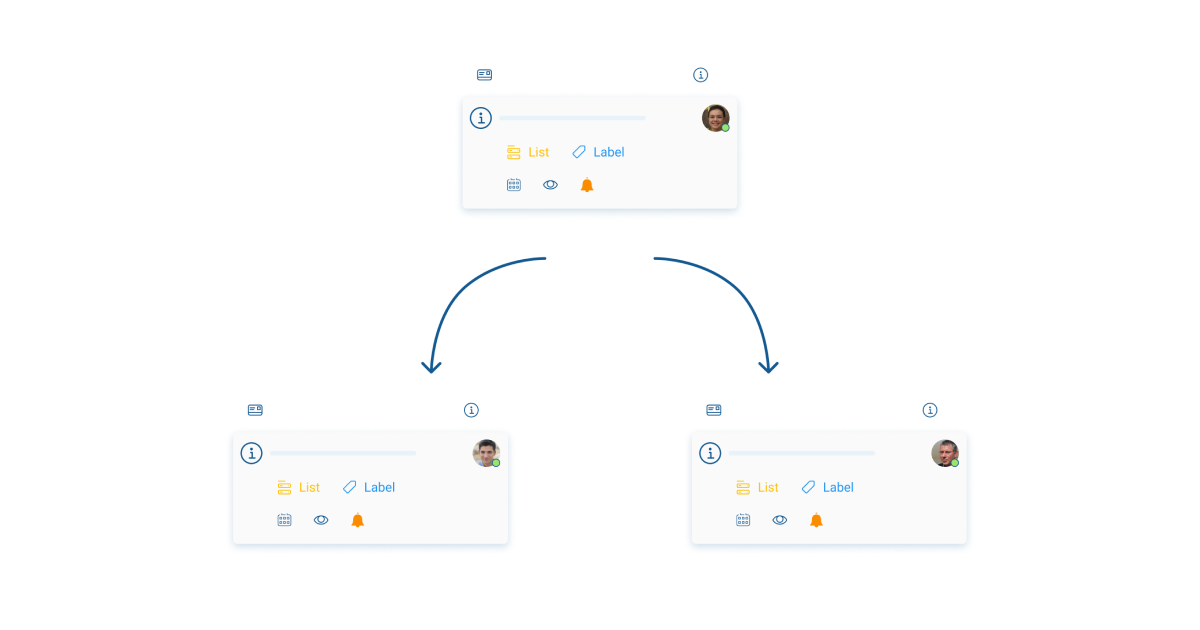

- Card relation: Highlight dependencies between tasks using Card Relation. This feature encourages a seamless workflow and can help in identifying problem areas more efficiently.

- User Activity Stream: Monitor individual performance and gain insights into who did what and when, leading to effective delegation of tasks, especially in the case of problem-solving.

- Document Folder: Store all relevant reports and analysis data systematically in Document Folders for easy access and reference.

What can readers expect after solving this challenge?

Implementing KanBo to overcome these existing hurdles ensures more efficient process management, quick problem identification, and prompt resolution. The platform's integrated workflow enhances communication and collaboration, leading to a more productive work environment. The long-term benefits include an elevated standard of quality control, decrease in a number of errors or issues, and overall manufacturing process improvement. As KanBo continues to evolve, future developments might include advanced analytics tools and integration capabilities with other technology already in use, enabling even smoother operations in managing quality control.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

KanBo for Quality Control in Automotive Battery Manufacturing

What do you need to know about this challenge?

In the fast-paced world of automotive manufacturing, one of the significant challenges is maintaining stringent quality control standards. This becomes notably prominent in the role of a Quality Engineer Technician at a battery manufacturing plant. Here, the challenge is twofold. Firstly, the technician needs to ensure all manufacturing processes are managed within set control requirements. Secondly, there is a need for detailed analyses of any cells/modules that fall out of these control limits, ensuring that only top-grade products reach the clients. This task requires careful attention to detail, effective data handling, and strong problem-solving skills while working in conjunction with different departments to enhance product quality.

What can you do with KanBo to solve this challenge?

KanBo's comprehensive array of features provides a robust solution to tackle these challenges:

- Space: Create separate spaces for individual processes. This segregation allows monitoring each process distinctly, facilitating efficient management.

- Card: Use cards to represent different tasks within each process. Cards can be used to identify tasks requiring special attention or any process falling outside the control limits.

- Activity Stream: The Activity Stream provides real-time updates of each process, keeping everyone informed and ensuring transparency across all stages.

- Card Status: Update Card Status regularly to keep track of task progression. This helps in quick identification of any issue that needs immediate attention.

- Card relation: Highlight dependencies between tasks using Card Relation. This feature encourages a seamless workflow and can help in identifying problem areas more efficiently.

- User Activity Stream: Monitor individual performance and gain insights into who did what and when, leading to effective delegation of tasks, especially in the case of problem-solving.

- Document Folder: Store all relevant reports and analysis data systematically in Document Folders for easy access and reference.

What can readers expect after solving this challenge?

Implementing KanBo to overcome these existing hurdles ensures more efficient process management, quick problem identification, and prompt resolution. The platform's integrated workflow enhances communication and collaboration, leading to a more productive work environment. The long-term benefits include an elevated standard of quality control, decrease in a number of errors or issues, and overall manufacturing process improvement. As KanBo continues to evolve, future developments might include advanced analytics tools and integration capabilities with other technology already in use, enabling even smoother operations in managing quality control.