Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Utilizing KanBo for Optimized Workflow and Increased Productivity in Automotive Industries

Best Practice

Conveniently manage layout design strategies using KanBo's activity stream, card blocker function, Card Dates, and Gantt Chart View in the automotive industry.

Why this Best Practice was created: To leverage KanBo's capabilities in managing efficient workflow and enhancing productivity using automation and robotics, a common demand in the automotive industry.

With increasing pressure to speed up production and improve efficiency, automotive industries are looking for tools that can help manage their layout design strategies effectively. Technology, robotics, and automation are playing an increasingly vital role in optimizing workflow in facilities and expanding productivity.

Challenge

Keeping track of workflow, managing potential issues, and coordinating tasks effectively can become overwhelming in a complex automotive production environment, making it hard to maintain efficiency and productivity.

Solution

Using KanBo's function can assist with this need in the following ways:

Activity Stream

Monitor and follow all actions in real-time ensuring no task or detail is missed.

Card Blocker

Identify potential issues preventing tasks from advancing, providing transparency in issues and bottlenecks.

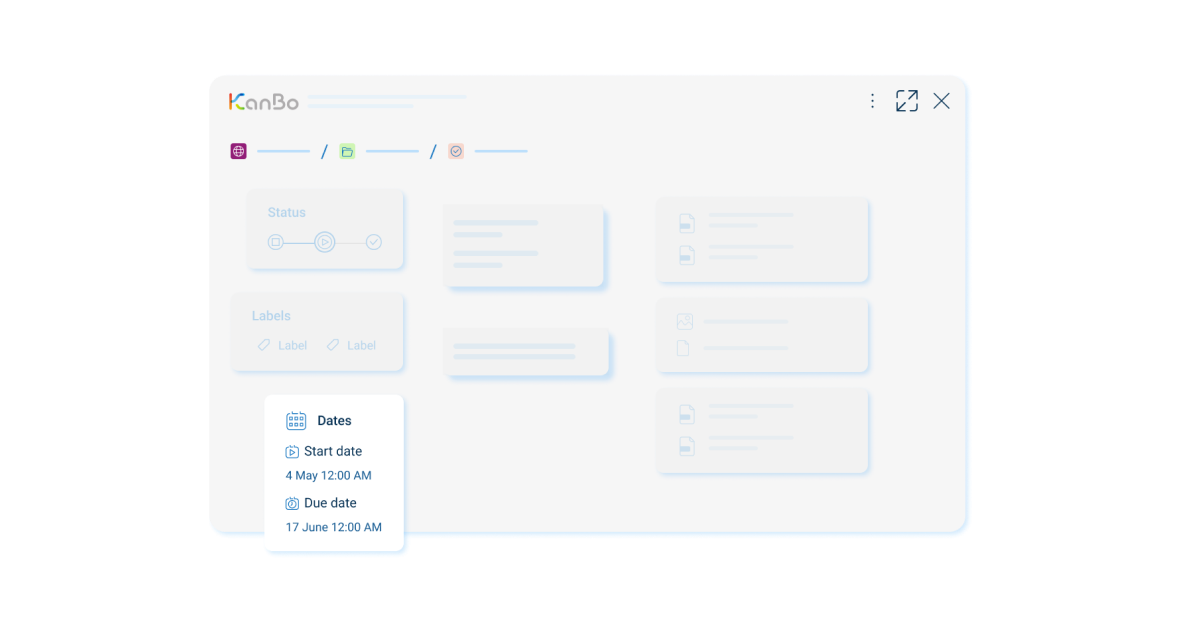

Card Dates

Outline significant dates, deadlines, and schedules which are crucial for maintaining a timely workflow.

Gantt Chart View

Visualize and plan your project to maintain an optimized workflow, and foresee potential overlaps or underutilized times.

Daily Routine

Begin each day by reviewing activity stream updates to stay informed about ongoing tasks. Regularly check Gantt Chart View for project timelines and potential conflicts.

Use Case

An automotive company can use the activity stream to track progress on designing a new assembly line. If a problem is detected like a delay in delivery of new robotic arm, card blocker can signal this issue. The company can then reference the Card dates and reschedule tasks on the Gantt Chart View to maintain workflow efficiency.

KanBo Tips

Leverage Gantt Chart View for visualizing and planning complex projects. Use the activity stream to stay updated with real-time actions on your tasks.

Learn more about how KanBo for Automotive can empower your company to maintain an optimized workflow and boost productivity in facilities.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Utilizing KanBo for Optimized Workflow and Increased Productivity in Automotive Industries

Best Practice

Conveniently manage layout design strategies using KanBo's activity stream, card blocker function, Card Dates, and Gantt Chart View in the automotive industry.

Why this Best Practice was created: To leverage KanBo's capabilities in managing efficient workflow and enhancing productivity using automation and robotics, a common demand in the automotive industry.

With increasing pressure to speed up production and improve efficiency, automotive industries are looking for tools that can help manage their layout design strategies effectively. Technology, robotics, and automation are playing an increasingly vital role in optimizing workflow in facilities and expanding productivity.

Challenge

Keeping track of workflow, managing potential issues, and coordinating tasks effectively can become overwhelming in a complex automotive production environment, making it hard to maintain efficiency and productivity.

Solution

Using KanBo's function can assist with this need in the following ways:

Activity Stream

Monitor and follow all actions in real-time ensuring no task or detail is missed.

Card Blocker

Identify potential issues preventing tasks from advancing, providing transparency in issues and bottlenecks.

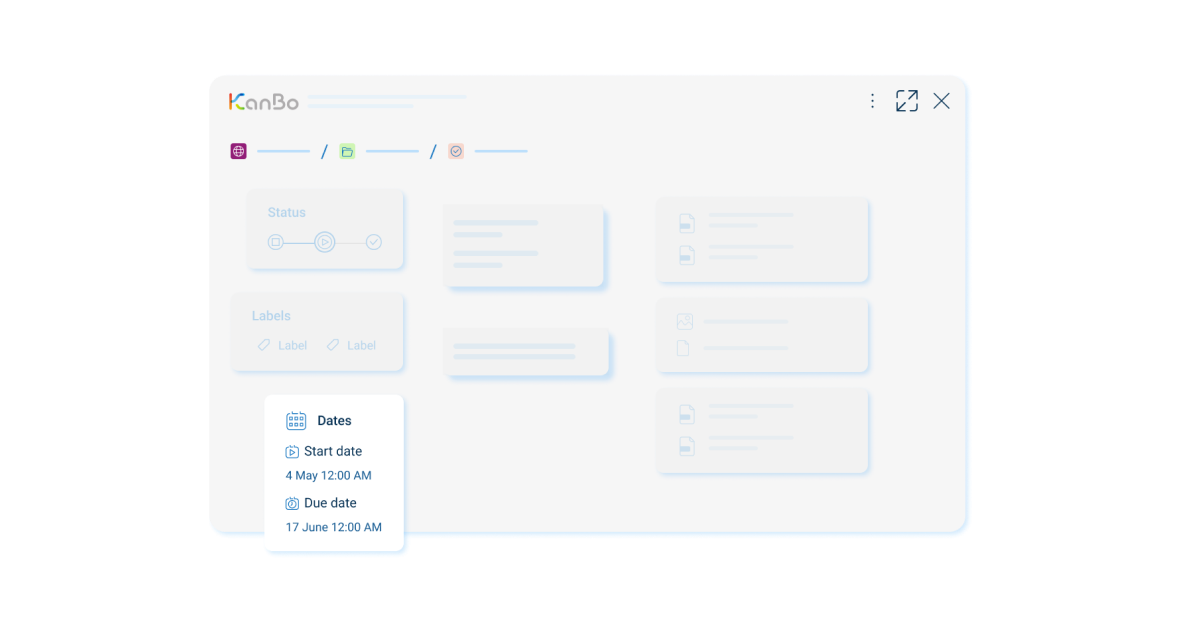

Card Dates

Outline significant dates, deadlines, and schedules which are crucial for maintaining a timely workflow.

Gantt Chart View

Visualize and plan your project to maintain an optimized workflow, and foresee potential overlaps or underutilized times.

Daily Routine

Begin each day by reviewing activity stream updates to stay informed about ongoing tasks. Regularly check Gantt Chart View for project timelines and potential conflicts.

Use Case

An automotive company can use the activity stream to track progress on designing a new assembly line. If a problem is detected like a delay in delivery of new robotic arm, card blocker can signal this issue. The company can then reference the Card dates and reschedule tasks on the Gantt Chart View to maintain workflow efficiency.

KanBo Tips

Leverage Gantt Chart View for visualizing and planning complex projects. Use the activity stream to stay updated with real-time actions on your tasks.

Learn more about how KanBo for Automotive can empower your company to maintain an optimized workflow and boost productivity in facilities.