Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Leveraging KanBo's Mind Map View to Visualize and Manage Project Priorities in the Automotive Industry

Best Practice

The usage of KanBo's Mind Map View to comprehend, visualize, and manage project hierarchies and priorities effectively in the vast landscape of the automotive industry.

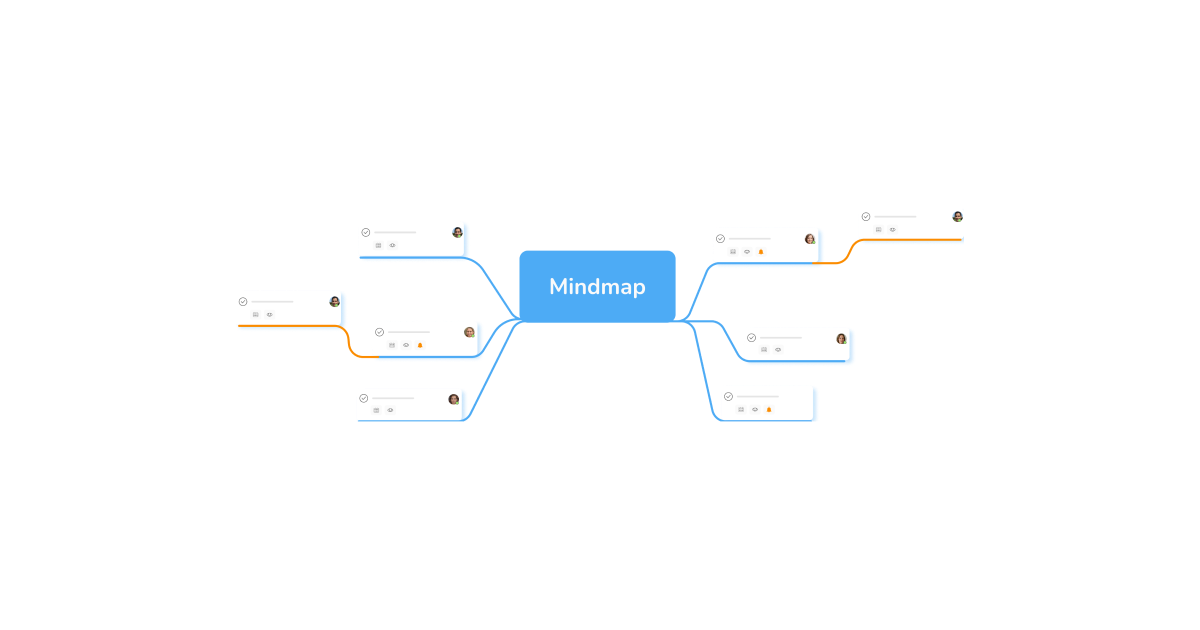

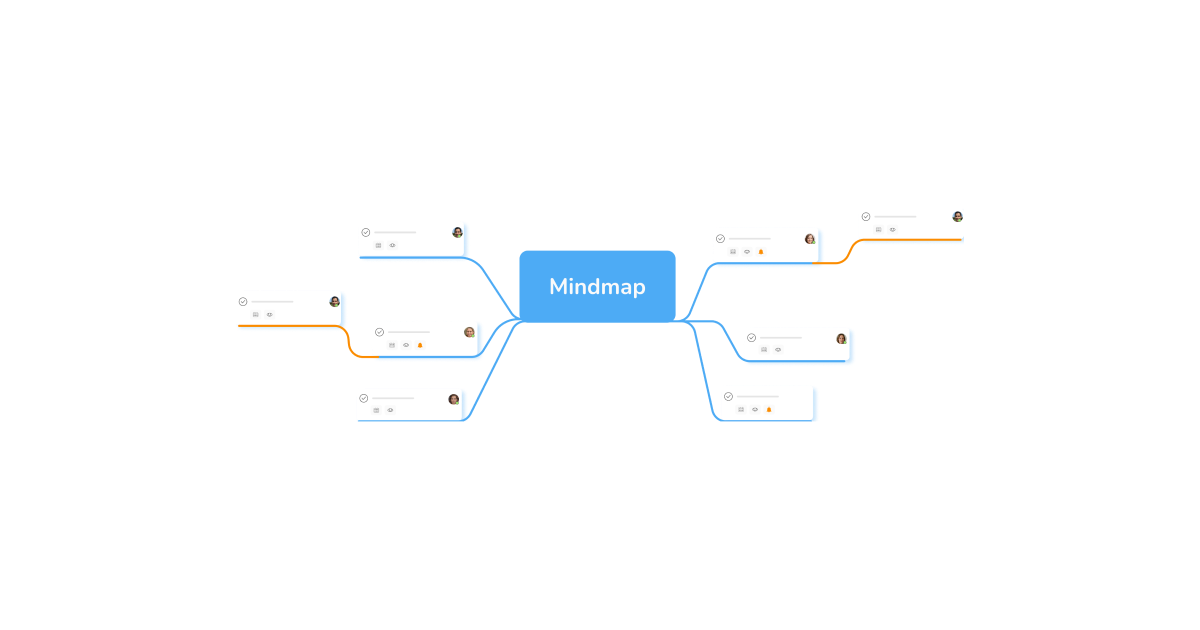

The Mind Map view is a key feature in KanBo that graphically represents the relations between cards. It provides a visual and individual approach to planning, arranging tasks, brainstorming, organizing thoughts and generating hierarchical structures in a single canvas.

This practice was created to address the challenge of understanding and managing multiple project priorities within extensive and complex industries like automotive, where multidimensional constituent elements can make prioritization a challenging process.

In the automotive industry, balancing multiple project priorities can be a daunting task. Understanding the hierarchy and conveying this to different teams allows for a more streamlined, efficient workflow. A crucial need is a tool that can visualize the project processes and priorities and enhance effective communication.

Challenge

The automotive industry involves juggling multiple projects. Determining and communicating whether designing an energy-efficient vehicle is of higher priority over developing autonomous driving technology can be complex.

Solution

Mind Map View

This feature allows managers to create a visual representation of the hierarchy of tasks and project priorities. As a result, complex structures and relationships can be understood at a glance.

The Mind Map view makes it easier to see the big picture and the details simultaneously. It provides a graphical representation of tasks, thus helping teams understand priorities and dependencies.

Daily Routine

On a typical day, project managers can use the Mind Map View to create, view, and modify project hierarchies. When new projects or tasks come in, they can add these to the Mind Map and adjust priorities as needed.

Use Case

For instance, if a decision has been made to prioritize the development of energy-efficient vehicles, this can quickly be visualized in the Mind Map View. This graphic can then be shared with all teams, ensuring everyone understands the new priority.

KanBo Tips

Implement regularly scheduled reviews of your Mind Map View in regular team meetings to ensure all stakeholders stay updated about current priorities and potential changes. This will foster an environment of clear communication and transparency.

Get started on creating a more efficient and streamlined product design process today with KanBo for Automotive.

Table of Contents

Work coordination platform

Designed for the automotive industry

As a leader in innovation, you understand the importance of staying ahead of the curve in the fast-moving automotive 4.0 world. KanBo provides you with the tools to do just that by facilitating smart factory operations, streamlining project management, fostering collaboration and solving complex problems.

Leveraging KanBo's Mind Map View to Visualize and Manage Project Priorities in the Automotive Industry

Best Practice

The usage of KanBo's Mind Map View to comprehend, visualize, and manage project hierarchies and priorities effectively in the vast landscape of the automotive industry.

The Mind Map view is a key feature in KanBo that graphically represents the relations between cards. It provides a visual and individual approach to planning, arranging tasks, brainstorming, organizing thoughts and generating hierarchical structures in a single canvas.

This practice was created to address the challenge of understanding and managing multiple project priorities within extensive and complex industries like automotive, where multidimensional constituent elements can make prioritization a challenging process.

In the automotive industry, balancing multiple project priorities can be a daunting task. Understanding the hierarchy and conveying this to different teams allows for a more streamlined, efficient workflow. A crucial need is a tool that can visualize the project processes and priorities and enhance effective communication.

Challenge

The automotive industry involves juggling multiple projects. Determining and communicating whether designing an energy-efficient vehicle is of higher priority over developing autonomous driving technology can be complex.

Solution

Mind Map View

This feature allows managers to create a visual representation of the hierarchy of tasks and project priorities. As a result, complex structures and relationships can be understood at a glance.

The Mind Map view makes it easier to see the big picture and the details simultaneously. It provides a graphical representation of tasks, thus helping teams understand priorities and dependencies.

Daily Routine

On a typical day, project managers can use the Mind Map View to create, view, and modify project hierarchies. When new projects or tasks come in, they can add these to the Mind Map and adjust priorities as needed.

Use Case

For instance, if a decision has been made to prioritize the development of energy-efficient vehicles, this can quickly be visualized in the Mind Map View. This graphic can then be shared with all teams, ensuring everyone understands the new priority.

KanBo Tips

Implement regularly scheduled reviews of your Mind Map View in regular team meetings to ensure all stakeholders stay updated about current priorities and potential changes. This will foster an environment of clear communication and transparency.

Get started on creating a more efficient and streamlined product design process today with KanBo for Automotive.